A workshop exhaust gas dust removal device

A dust removal device and workshop exhaust gas technology, applied in the field of air purification, can solve the problems of simple structure, affecting the quality of dust removal, poor dust removal effect, etc., and achieve the effect of convenient pulling and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

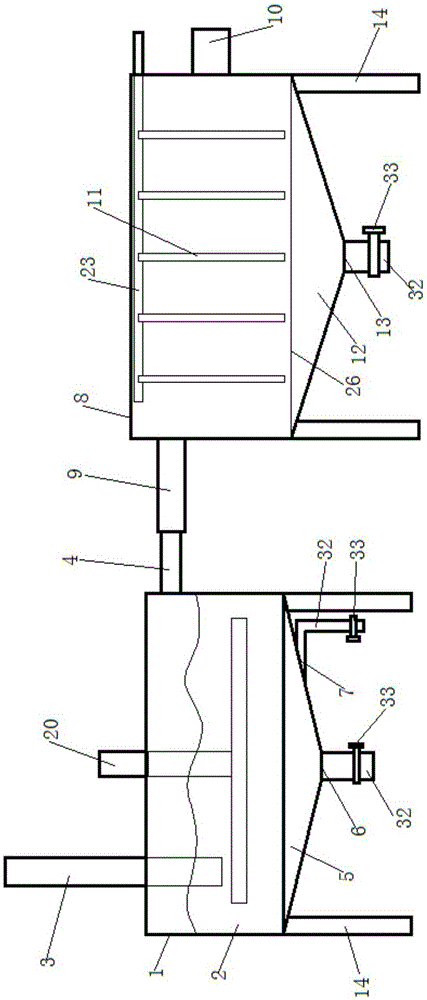

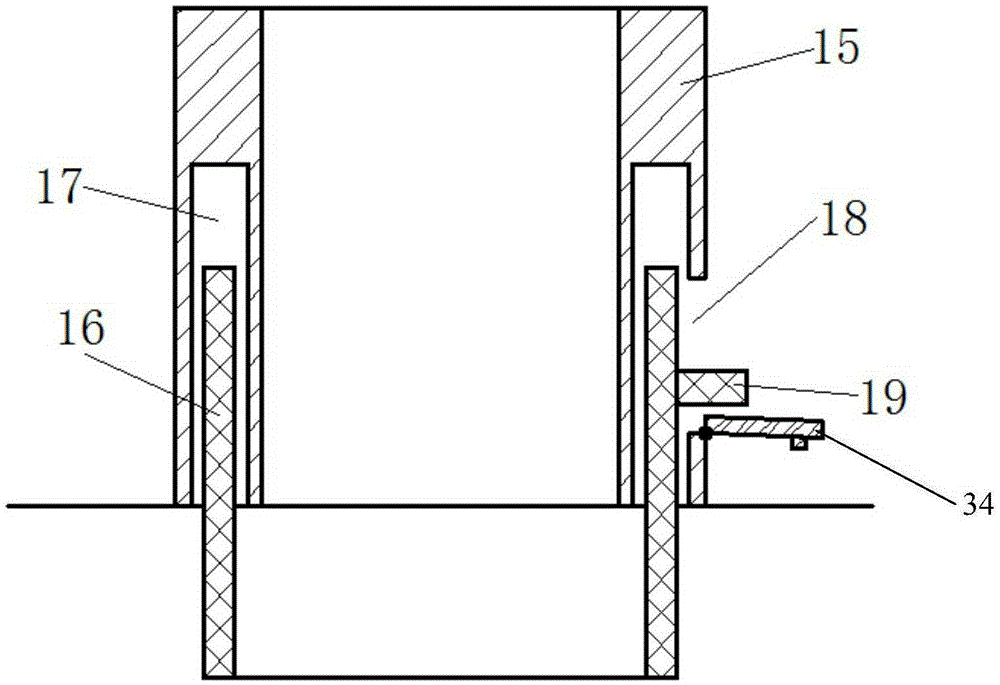

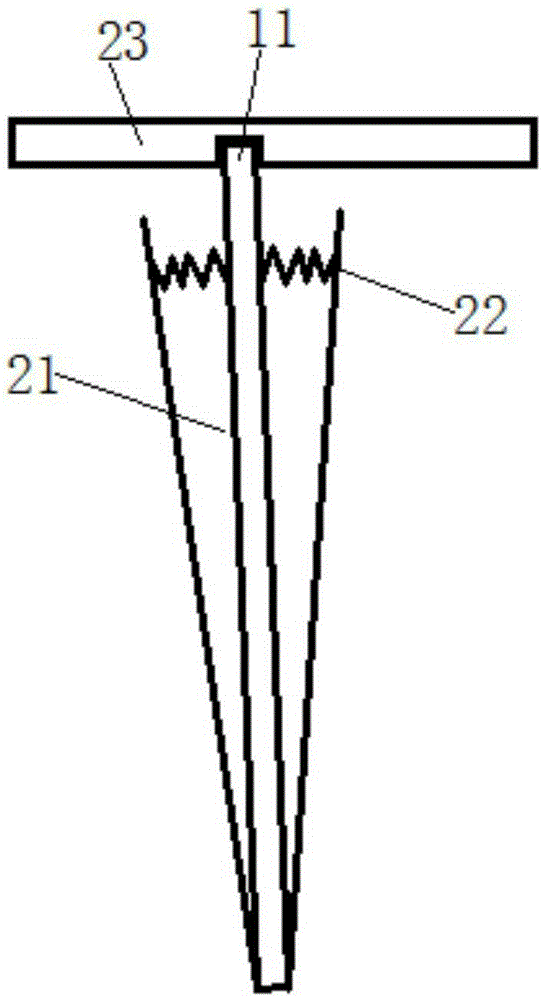

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] figure 1 The first specific embodiment of the present invention is shown: a plant waste gas dedusting device, including a liquid dedusting device and a solid dedusting device, the liquid dedusting device includes a liquid dedusting box 1, and the liquid dedusting box 1 is provided with water 2, the water level The line is 1 / 2 to 4 / 5 of the depth of the entire liquid dust removal box 1, and the top of the liquid dust removal box 1 is provided with a first air intake pipe 3 in the vertical direction, and the lower end opening of the first air intake pipe 3 is located below the horizontal plane. A first air outlet pipe 4 is provided on the side wall away from the first air inlet pipe 3 above the liquid dust removal box 1, and an impurity sedimentation tank 5 is arranged at the bottom of the liquid dust removal box 1. The impurity sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com