Quick-install locking mechanism and working method of oblique axis pressing block

A locking mechanism and working method technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of filtered gas leakage, poor filtering effect, poor sealing, etc., to achieve improved sealing and filtering effects, improve sealing and filtering Effect, the effect that the ease of disassembly improves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

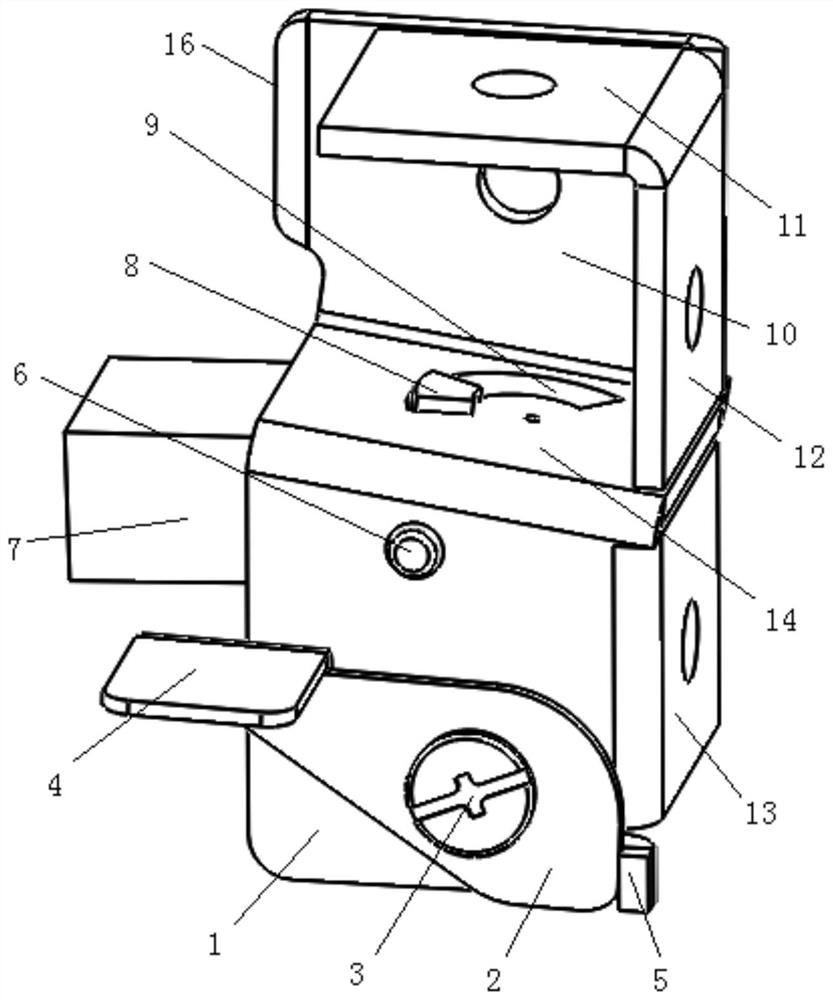

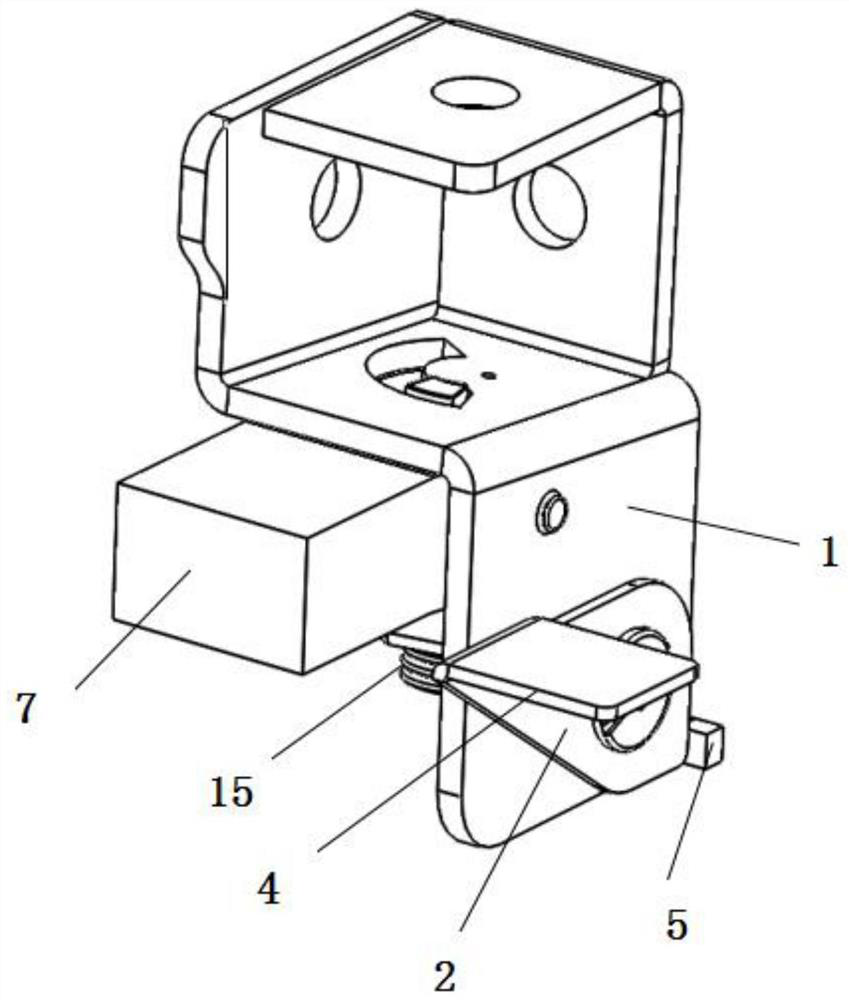

[0038] like Figure 1-Figure 2 As shown in the figure, a quick-loading and locking mechanism for an oblique axis pressure block is disclosed, which includes a reference plate 14, and the reference plate 14 is rotatably connected with a pressure block 7; the pressure block 7 is used for locking the fixing member;

[0039] The bottom edge of the reference plate 14 is provided with a bracket 1, and a side part of the bracket 1 is rotatably connected with a buckle 2; the buckle 2 is used to support the fixing piece; Keep it flush, the other end is longer than the bracket 1 in the horizontal direction, and the protruding part is used to support the fixing piece; the present invention can realize the safe and fast disassembly and replacement of the filter by one person by pulling the buckle itself, and ensure the disassembly and assembly of the filter. During the process, the risk of filter falling is prevented, and the safety, convenience and speed of operation are improved;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com