System for making iced coffee and iced juice, and method for making iced coffee

An iced juice and coffee technology, applied in the field of iced coffee and iced juice production systems, can solve the problems of difficult microorganisms and pests, uncertain food safety risks, high costs, etc., to ensure food safety, perfect customer experience, and the lowest cost. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

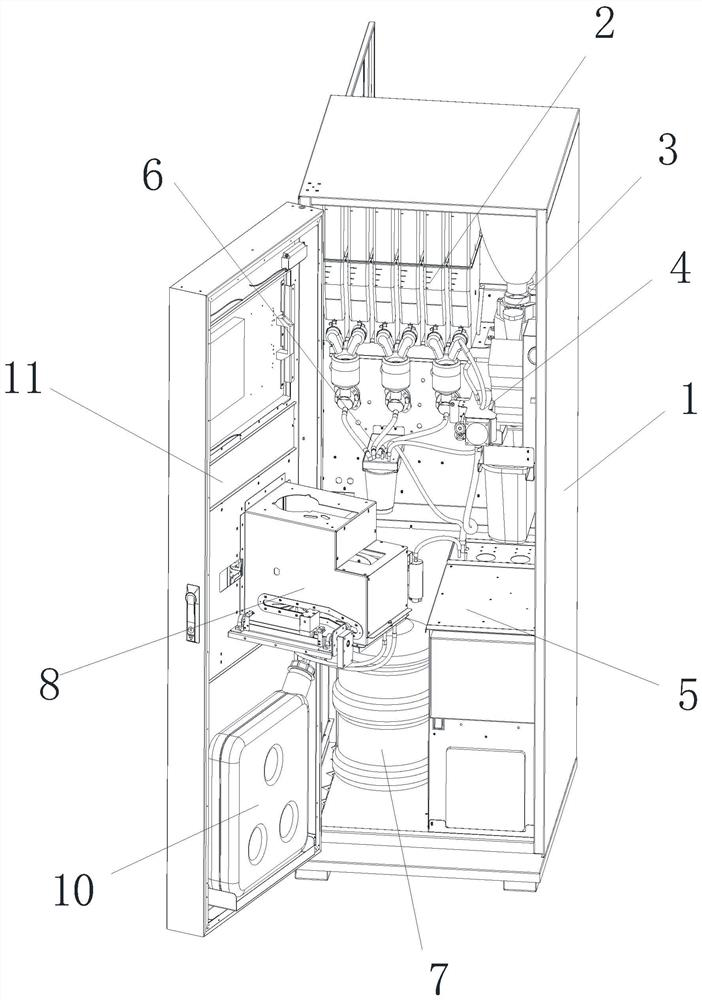

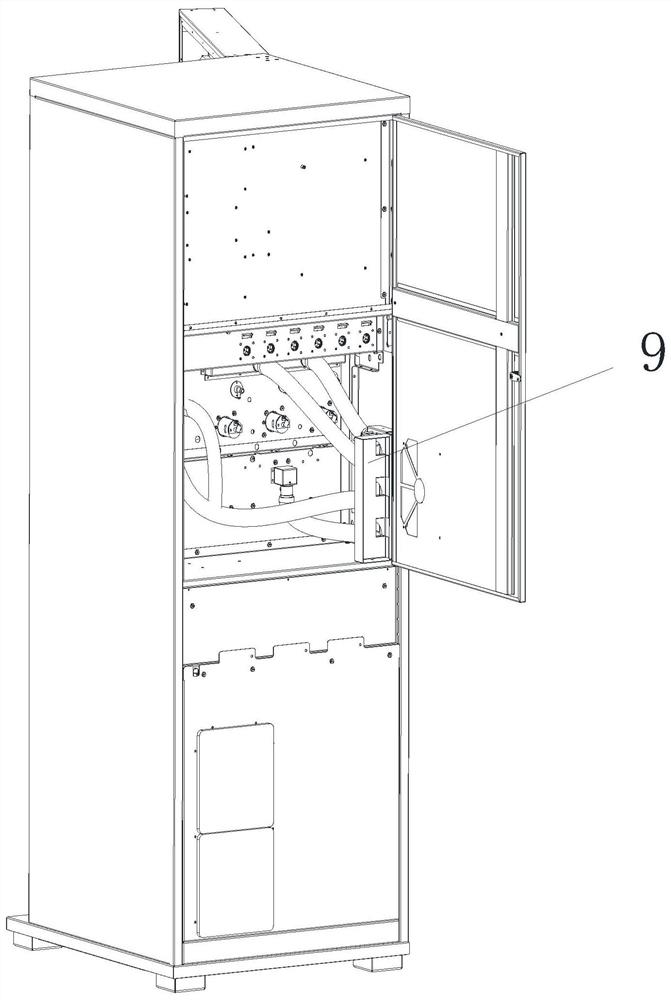

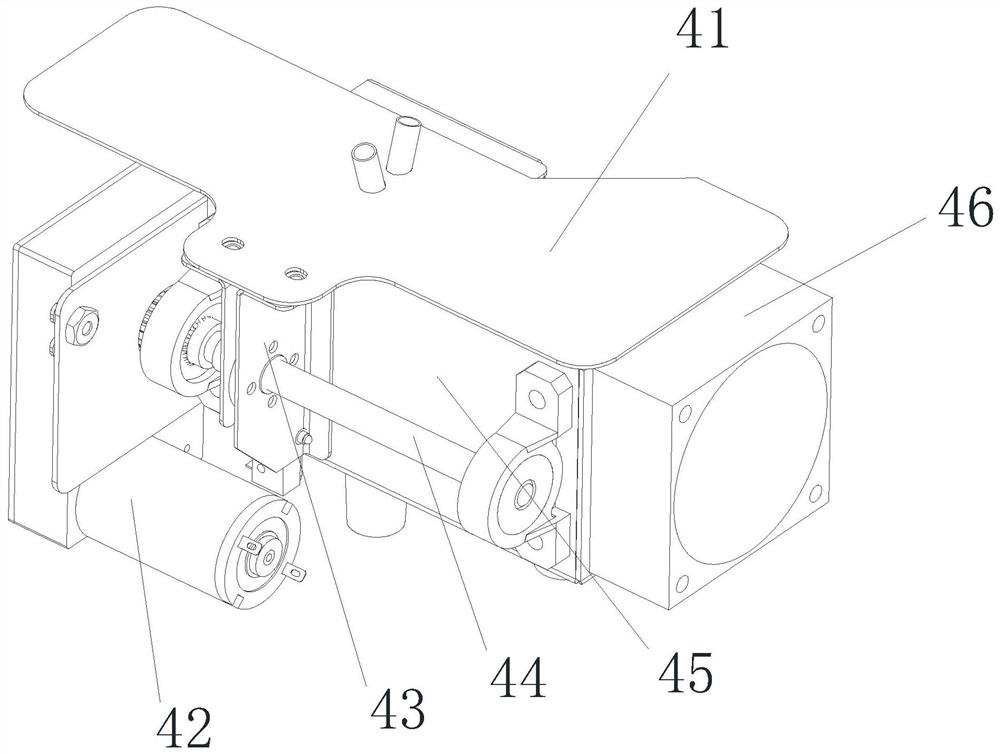

[0031] The preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be

[0042] It should be noted that the parts not involved in the present invention are the same as the prior art or can be realized by using the prior art.

[0043] In the description of the embodiments of the present invention, unless otherwise expressly specified and limited, the terms "installed", "connected", "connected"

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap