A robotic arm control device and control method for electrostatic spraying of auto parts

An electrostatic spraying and control device technology, applied in electrostatic spraying devices, spraying devices, liquid spraying equipment, etc., can solve the problems of different impact force, inconsistent uniformity, etc., and achieve stable airflow parameters, flexible and adjustable size, reduce The effect of execution difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

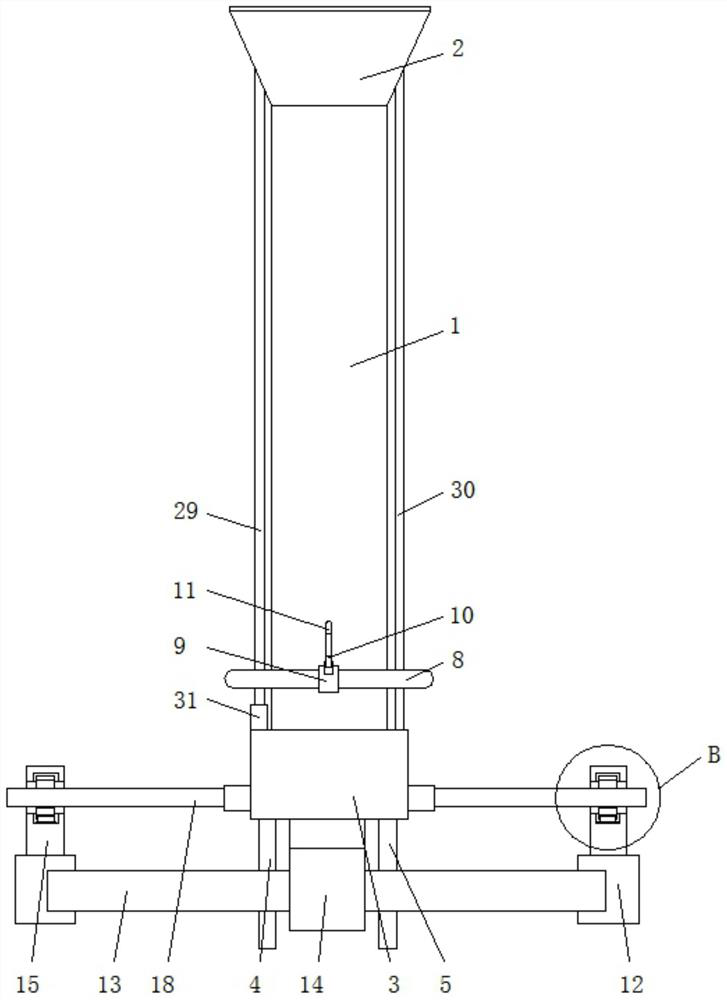

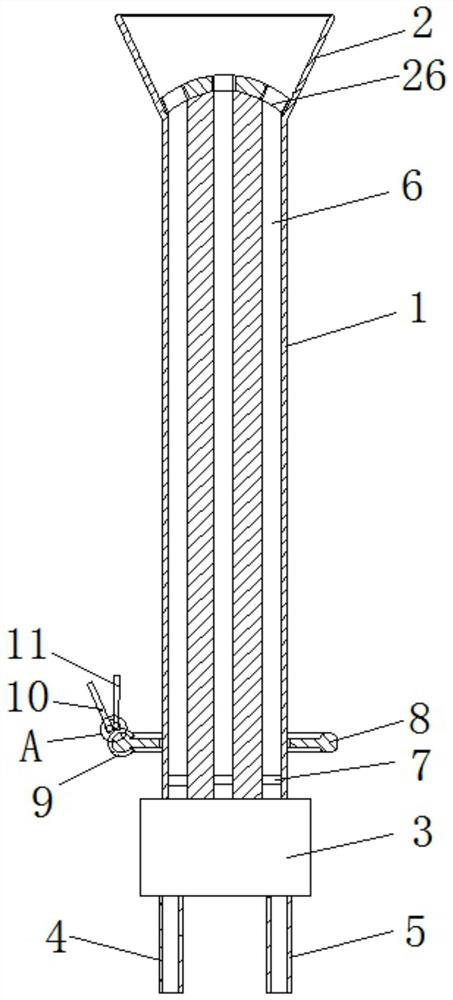

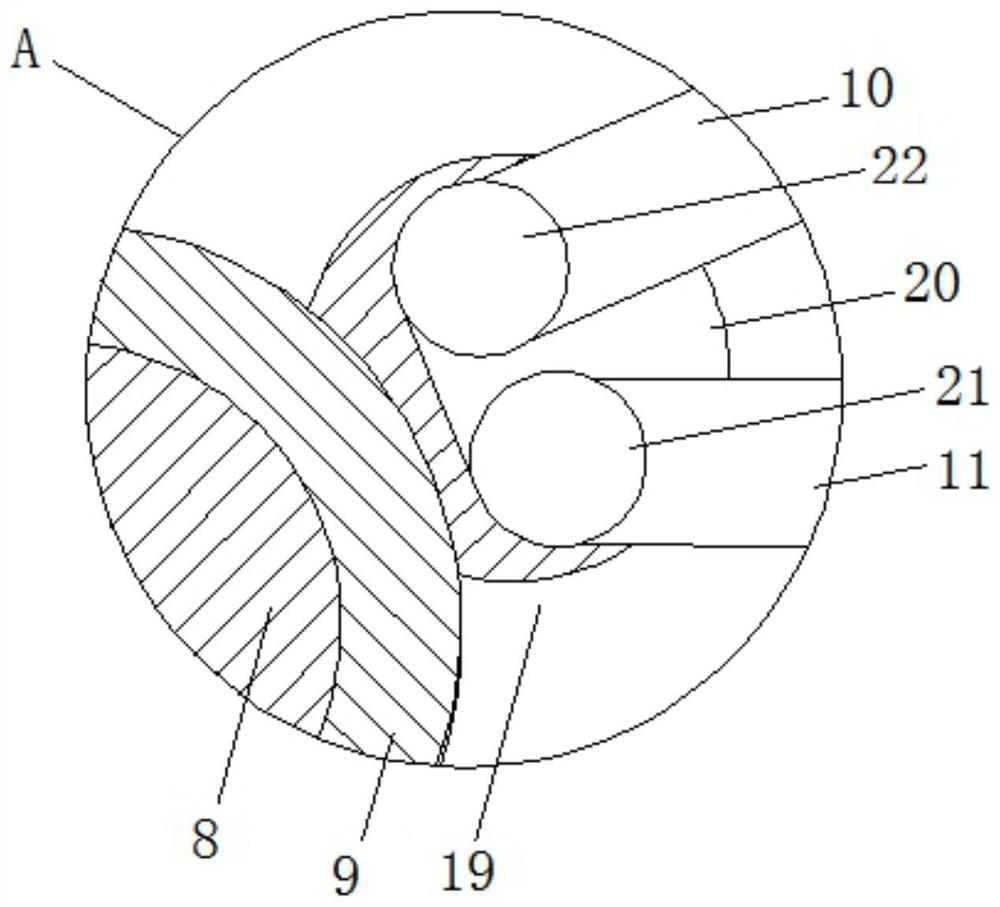

[0033] according to figure 1 , 2 , 3, 4, 5, 6, and 7, the present embodiment proposes a mechanical arm control device and control method for electrostatic spraying of automobile parts, including a spraying mechanism, a robotic arm mechanism and a main controller, the spraying mechanism It is connected with the mechanical arm mechanism, and the spraying mechanism includes a conveying body 1. The upper and lower ends of the conveying body 1 are respectively equipped with a spray cup 2 and a mixer 3, and the left and right sides below the mixer 3 are respectively provided with powder pipes 4. and the air duct 5, and the upper ends of the powder duct 4 and the air du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com