Pressing molding technology for ultra-long refractory material tank body

A technology for press forming and refractory materials, which is applied in the direction of manufacturing tools, ceramic forming machines, auxiliary forming equipment, etc., which can solve the problem of inability to achieve efficient, accurate, safe and stable super-long refractory tank pressing and unreasonable press forming process design. , unreasonable design of the pressing process, etc., to achieve the effects of precise and safe forming and pressing operations, high qualified rate of finished products and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

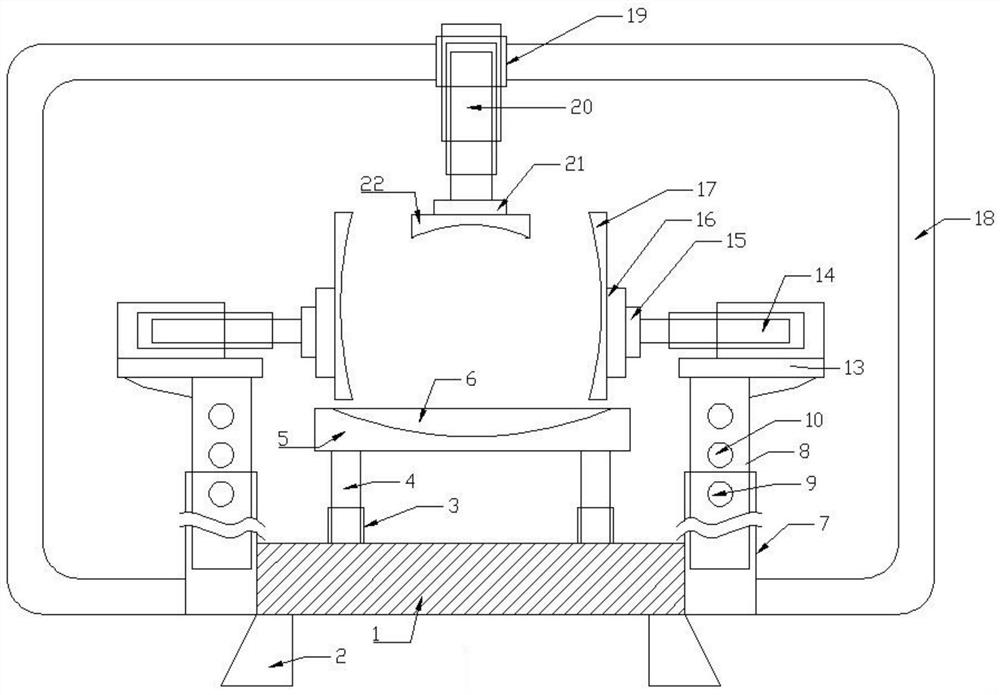

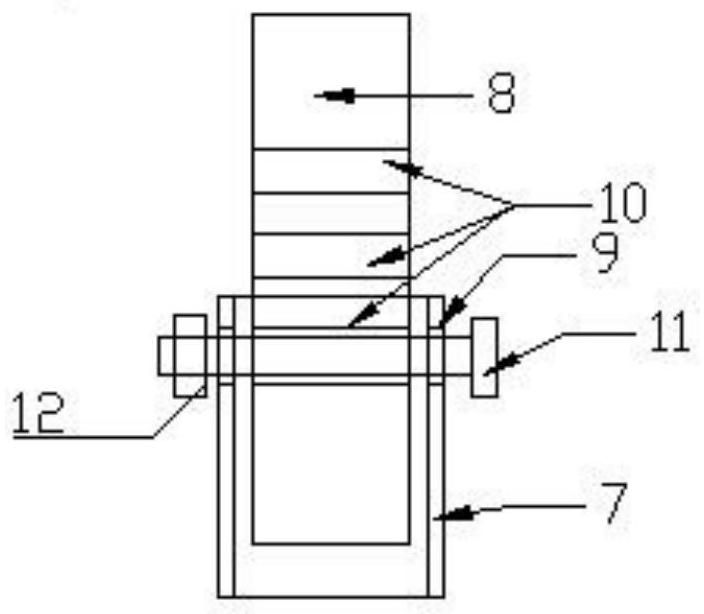

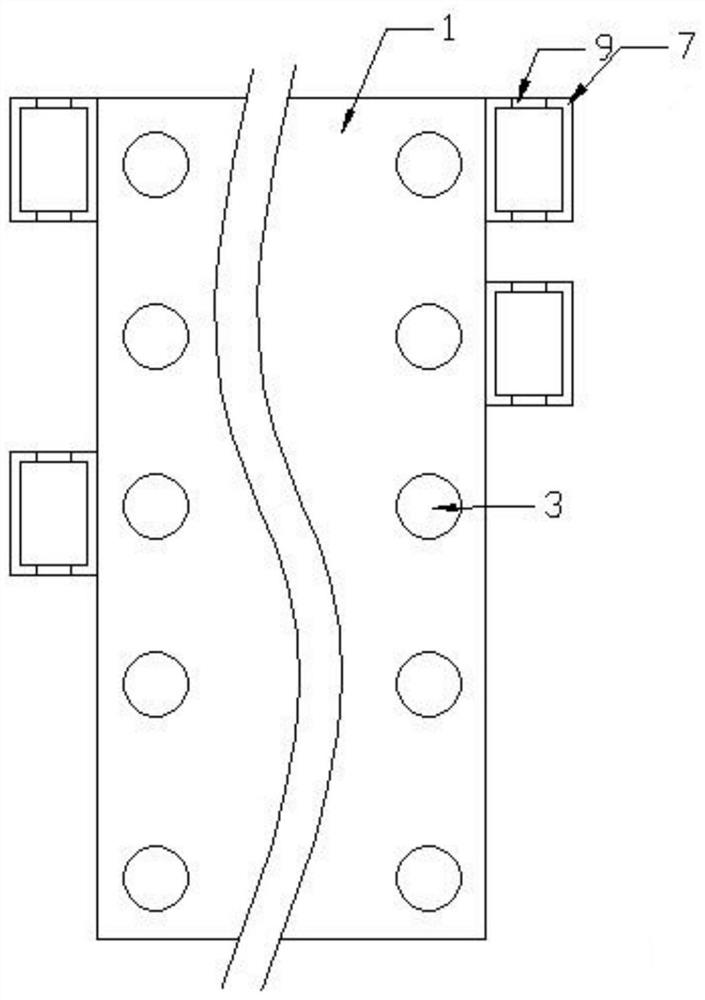

[0016] Such as figure 1 , figure 2 , image 3 with Figure 4 Shown is a press-forming process for an ultra-long refractory tank body, the press-forming process is completed by a horizontal support assembly and a press-forming assembly used in conjunction with the horizontal support assembly; the horizontal support assembly includes a horizontal support plate 1, and Several support legs 2 arranged on the bottom surfaces of both sides of the horizontal support plate 1, and several hollow spacer sleeves 3 symmetrically arranged on the upper end surfaces of both sides of the horizontal support plate 1, and used in conjunction with several hollow spacer sleeves 3 respectively The circular support column 4, and the tank body limit plate 5 respectively connected to one end of the circular support column 4, and the tank body limit groove 6 arranged in the tank body limit plate 5; the press-molded assembly, It includes several auxiliary hollow limit sleeves 7 symmetrically arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com