Three-beam gate type dual-power intelligent nuclear head molding press

An intelligent, door-type technology, applied in other home appliances, household appliances, applications, etc., can solve the problems of inability to realize efficient, accurate, safe and stable molding mechanical products, increase the economic cost of enterprises, and high product scrap rate, so as to achieve safety and stable forming and pressing processing operations, reducing production economic costs, and high yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

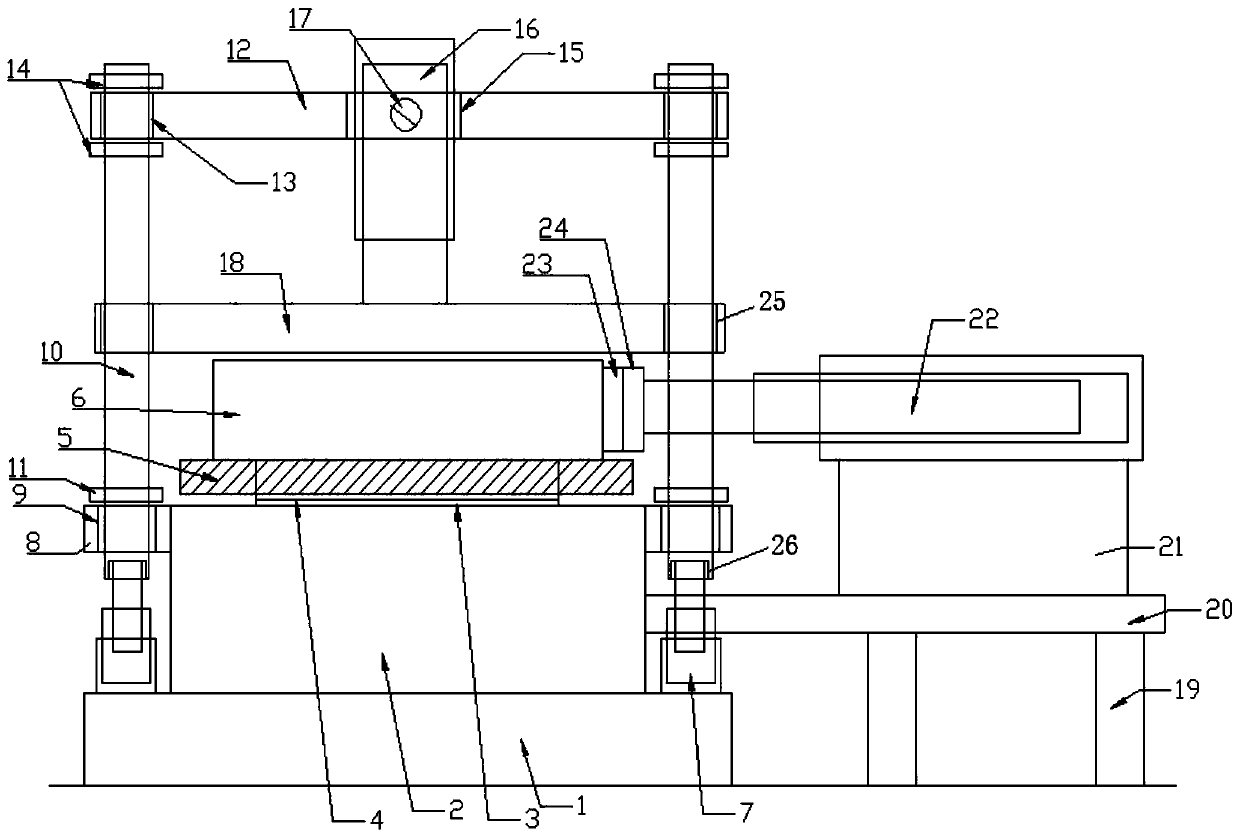

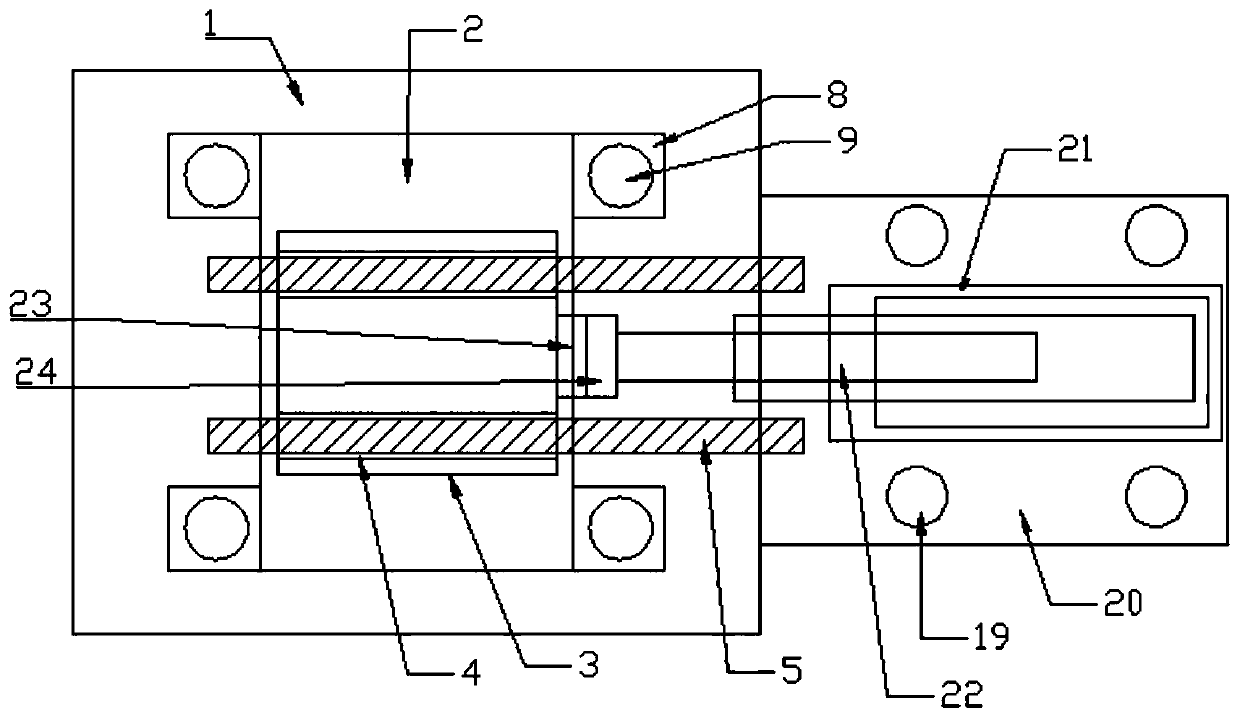

[0016] Such as figure 1 and figure 2 A three-beam portal type double-action intelligent nuclear power head forming press shown is composed of a vertical forming pressing assembly and a horizontal push-pull assembly used in conjunction with the vertical forming pressing assembly; the vertical forming pressing assembly, It includes a base 1, a workbench 2 arranged on one side of the base 1, a horizontal guide bar 3 symmetrically arranged on one side of the workbench 2, and slide rail grooves 4 respectively arranged in one side of the transverse guide bar 3, and respectively snapped into The strip-shaped support slide rail 5 in the slide rail groove 4, and the intelligent nuclear power forming lower head mold 6 arranged on one side of the strip-shaped support slide rail 5, and the fixing method arranged on the outer wall of one end of the intelligent nuclear power forming lower head mold 6 Lan 23, and the vertical support oil cylinder 7 arranged on the four corners of the base ...

Embodiment 2

[0018] Such as figure 1 and figure 2 A three-beam gantry type double-action intelligent nuclear power head forming press shown includes a vertical forming and pressing assembly, and a horizontal push-pull assembly used in conjunction with the vertical forming and pressing assembly; the vertical forming and pressing assembly, It includes a base 1, a workbench 2 arranged on one side of the base 1, a horizontal guide bar 3 symmetrically arranged on one side of the workbench 2, and slide rail grooves 4 respectively arranged in one side of the transverse guide bar 3, and respectively snapped into The strip-shaped support slide rail 5 in the slide rail groove 4, and the intelligent nuclear power forming lower head mold 6 arranged on one side of the strip-shaped support slide rail 5, and the fixing method arranged on the outer wall of one end of the intelligent nuclear power forming lower head mold 6 Lan 23, and the vertical support oil cylinder 7 arranged on the four corners of th...

Embodiment 3

[0020] Such as figure 1 and figure 2 A three-beam gantry type double-action intelligent nuclear power head forming press shown includes a vertical forming and pressing assembly, and a horizontal push-pull assembly used in conjunction with the vertical forming and pressing assembly; the vertical forming and pressing assembly, It includes a base 1, a workbench 2 arranged on one side of the base 1, a horizontal guide bar 3 symmetrically arranged on one side of the workbench 2, and slide rail grooves 4 respectively arranged in one side of the transverse guide bar 3, and respectively snapped into The strip-shaped support slide rail 5 in the slide rail groove 4, and the intelligent nuclear power forming lower head mold 6 arranged on one side of the strip-shaped support slide rail 5, and the fixing method arranged on the outer wall of one end of the intelligent nuclear power forming lower head mold 6 Lan 23, and the vertical support oil cylinder 7 arranged on the four corners of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com