Patents

Literature

38 results about "Semi-formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

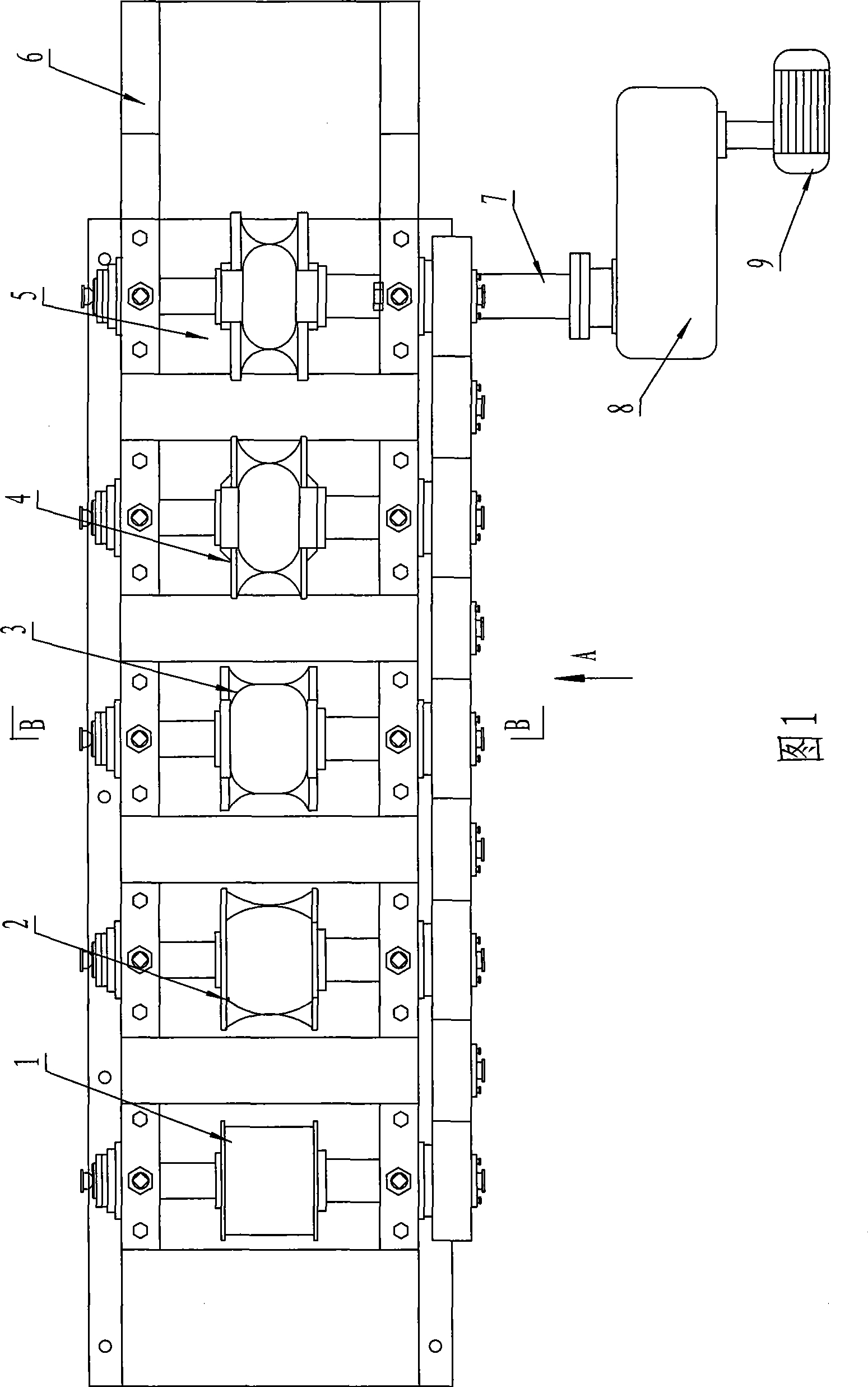

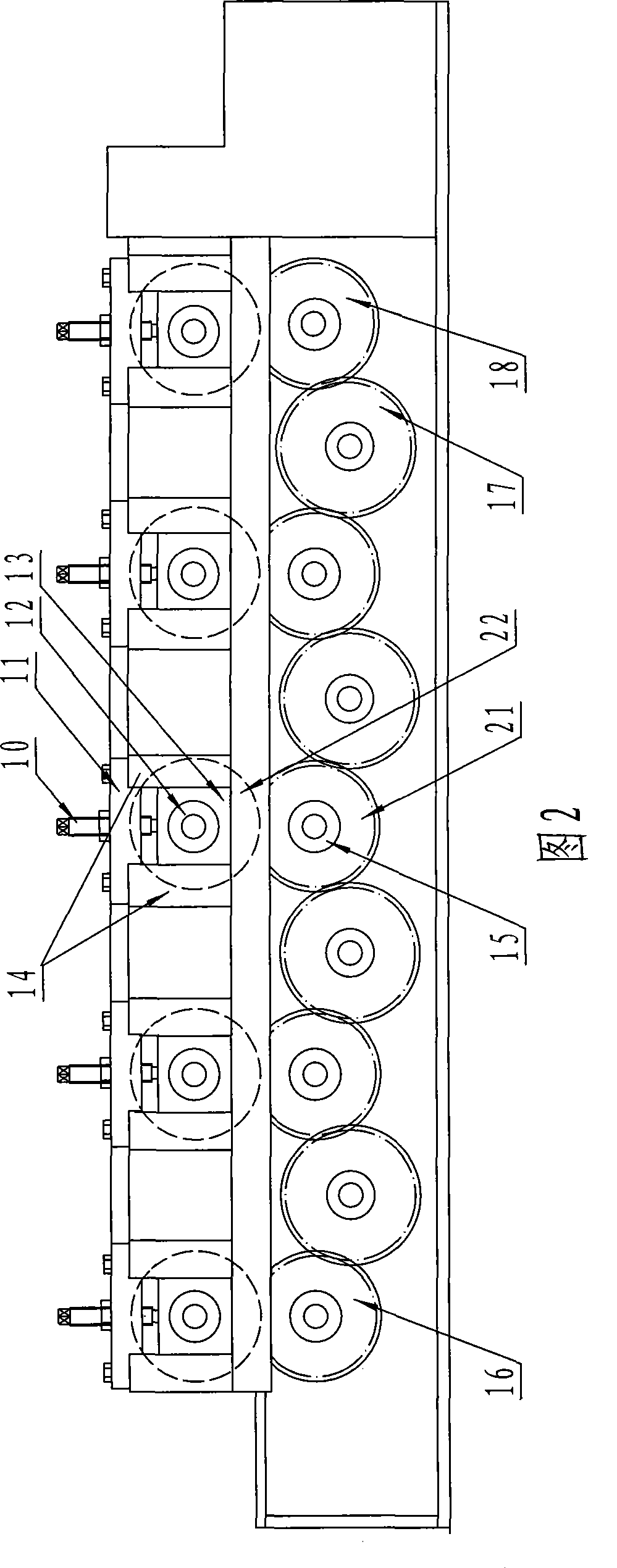

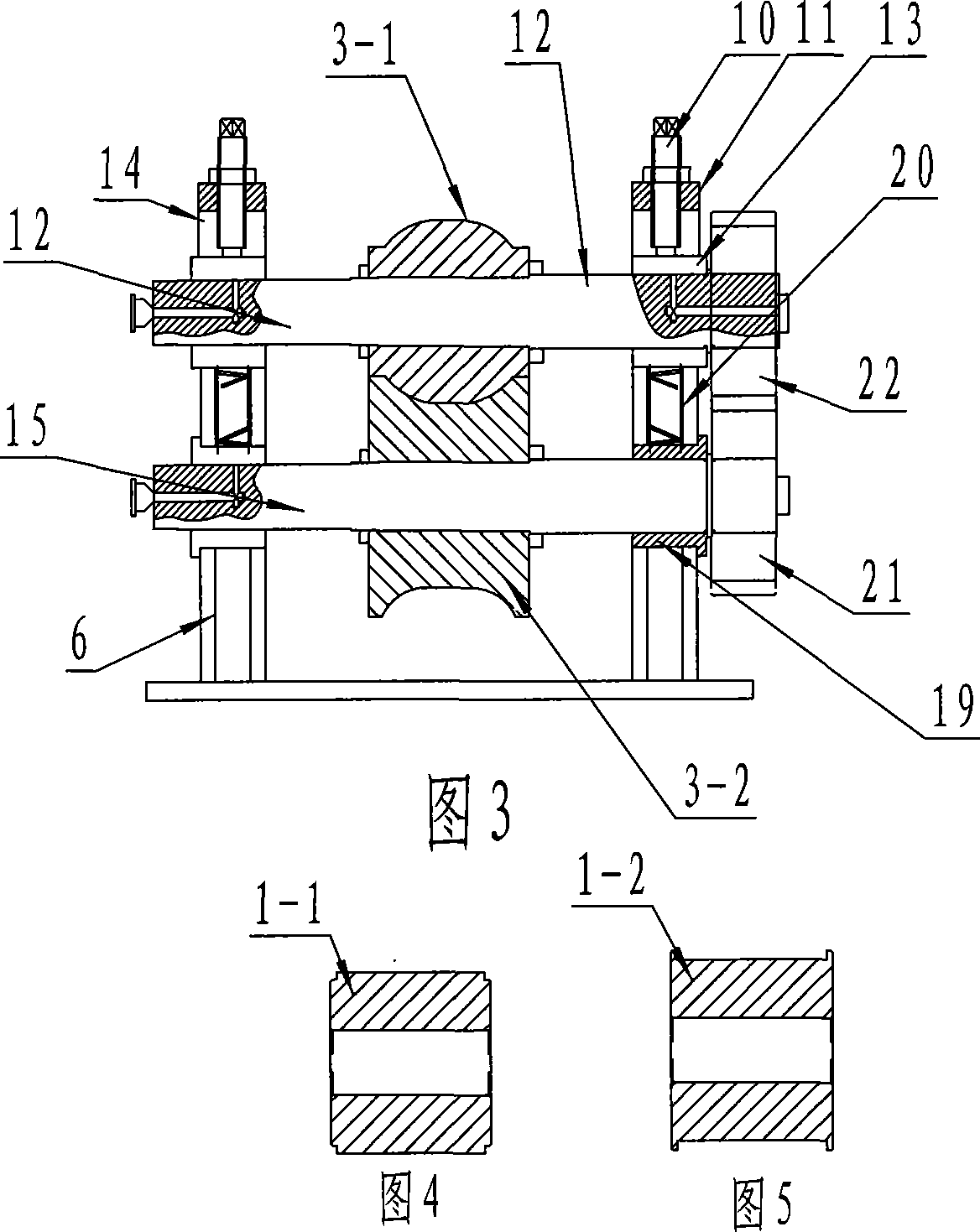

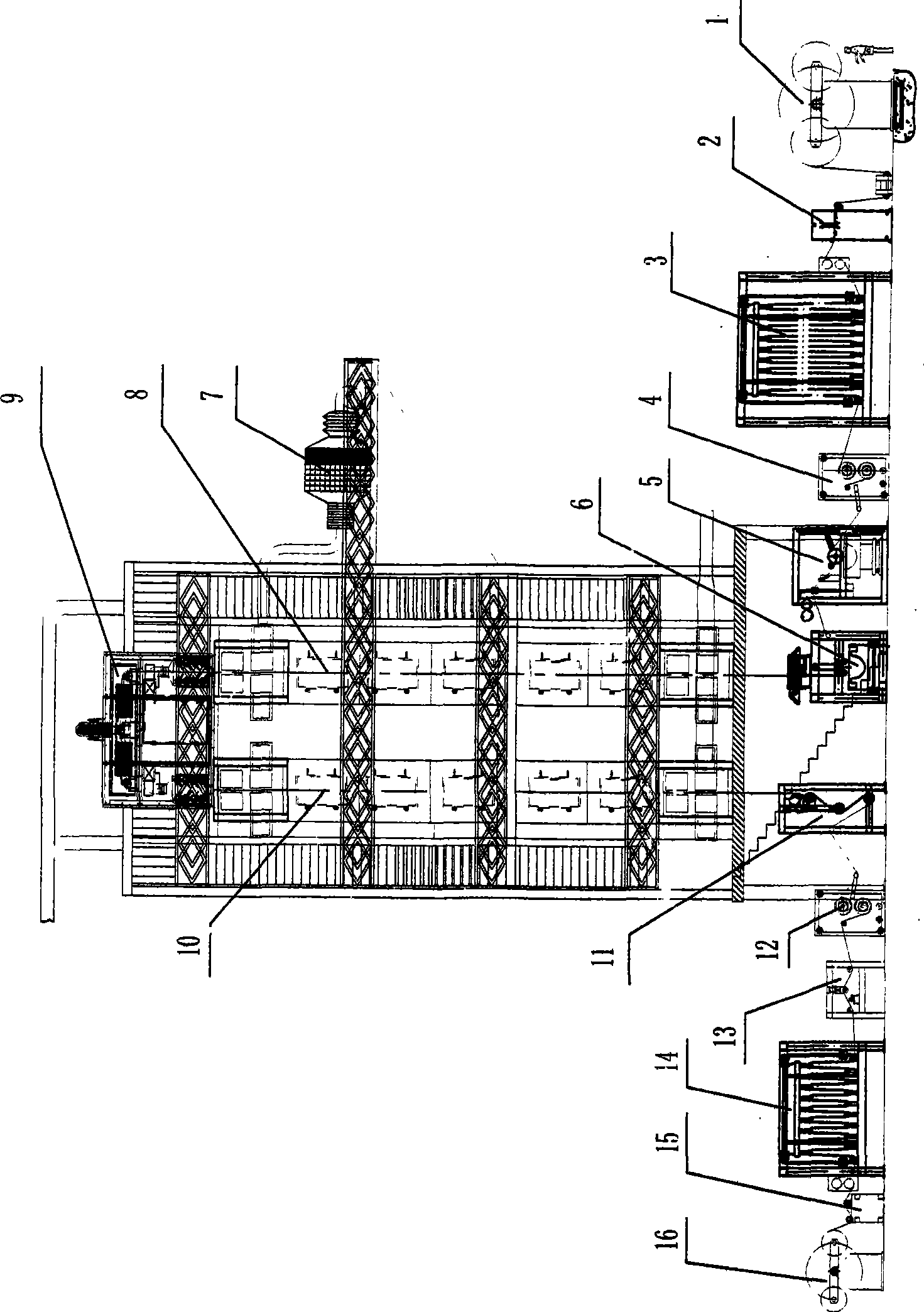

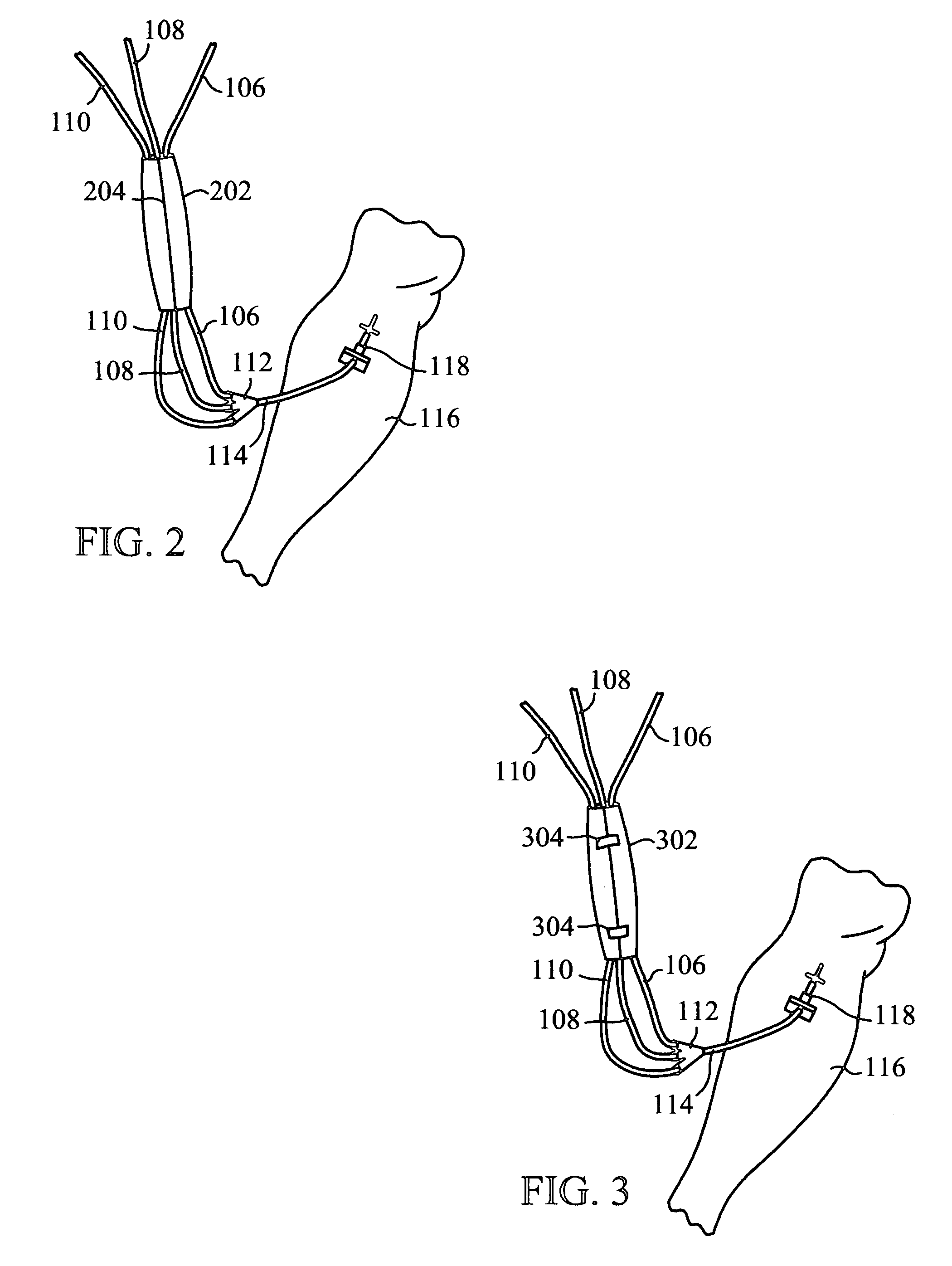

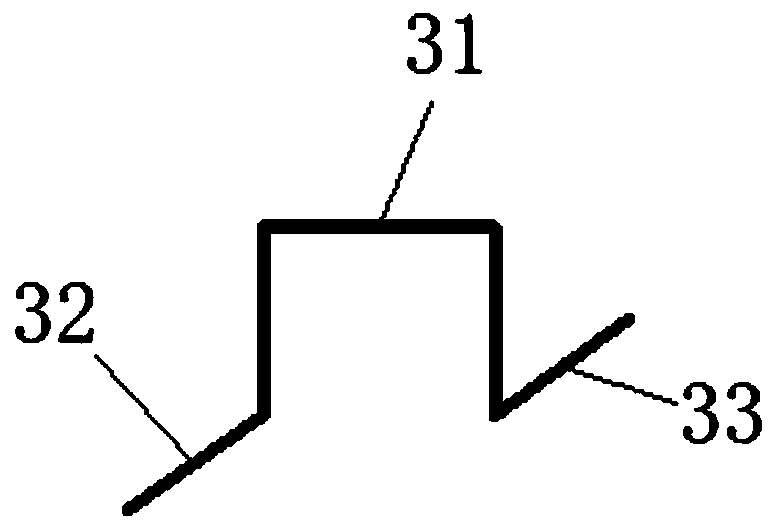

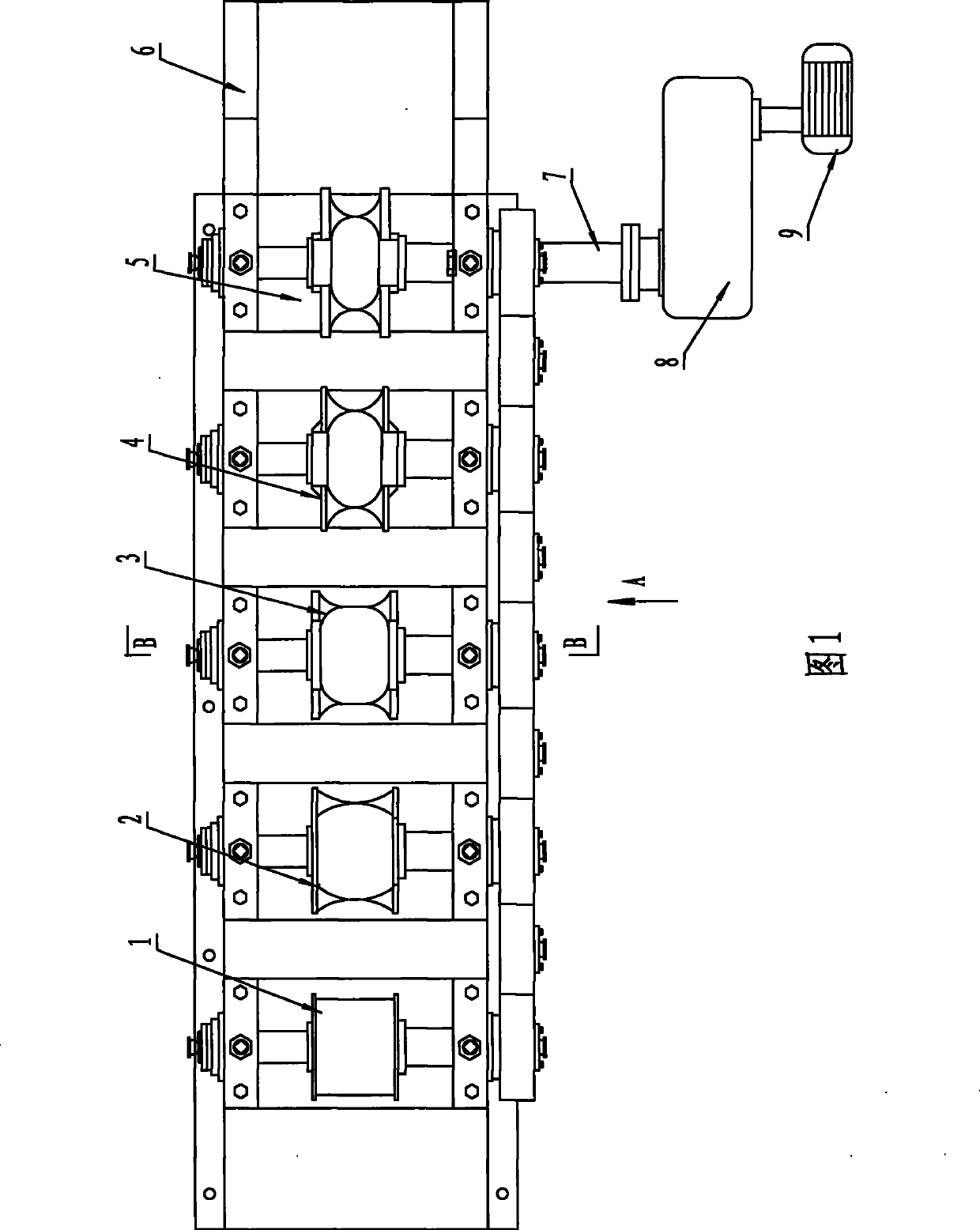

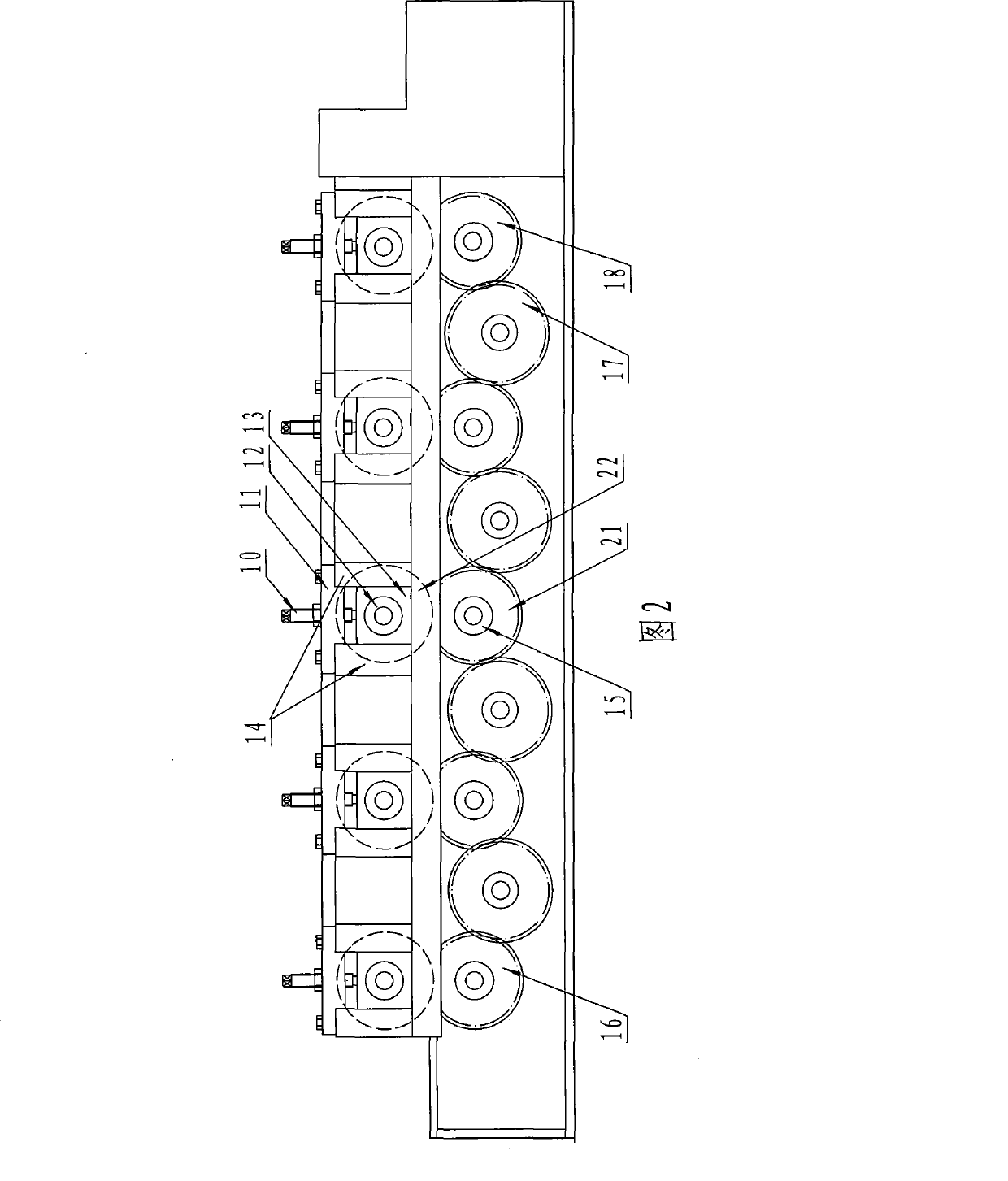

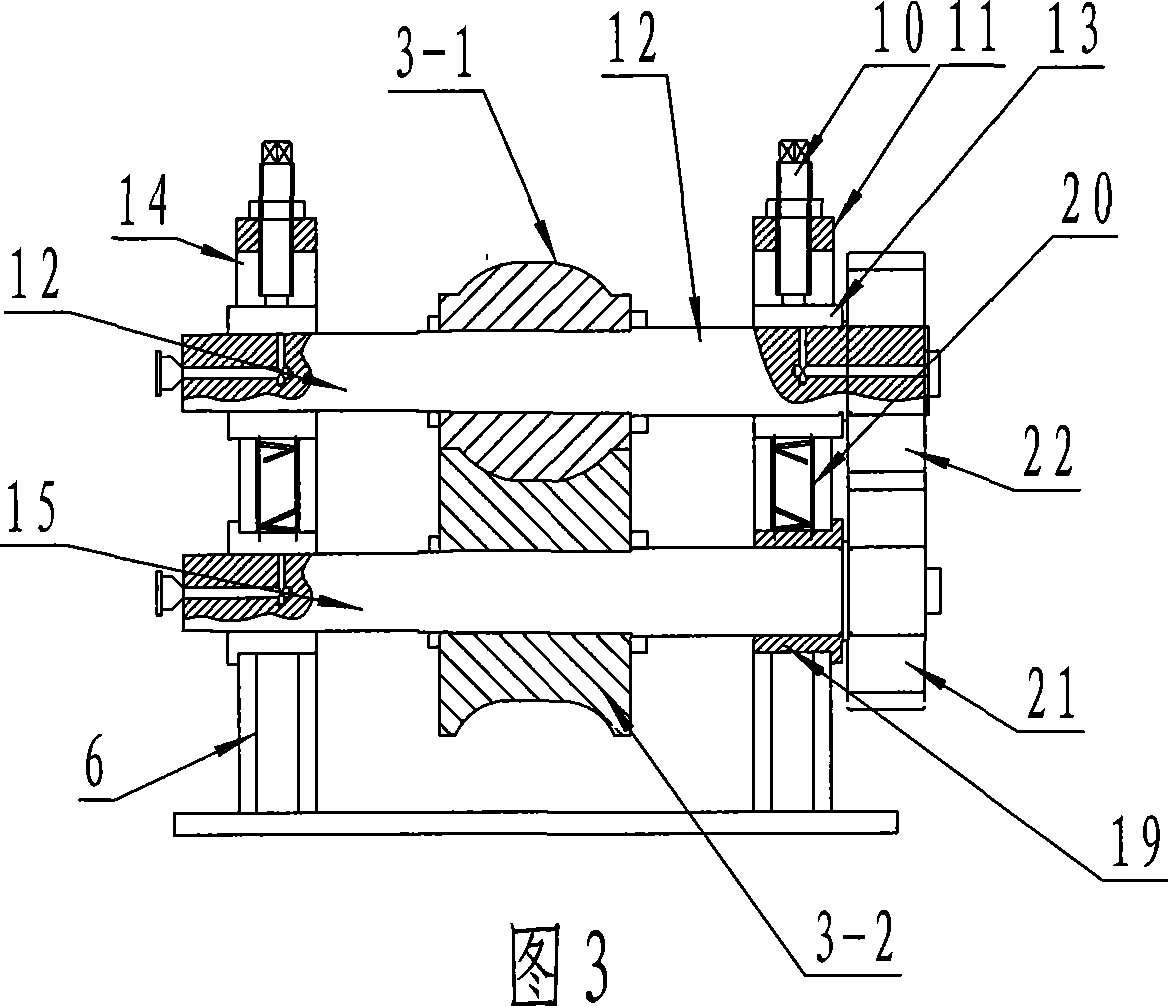

Semicanal formation rolling machine

ActiveCN101386023AReduce stiffnessImprove flexibilityMetal rolling stand detailsRollsSteel beltHelix

A rolling mill for forming a semi-tube belongs to the technical field of rolling, and is used for solving the problem of one-time forming of steel strips. The technical proposal is that the rolling mill comprises a frame, a rolling part, a transmission part and a cogging adjusting mechanism. The rolling part consists of a guide roller, a pre-forming roller, a semi-forming roller, a forming roller and a rolling roller which are arranged in sequence. The upper roller and the lower roller of the guide roller are cylindrical rollers, while the other four rollers respectively consist of upper rollers and lower rollers which are provided with mutually matched arc roll surfaces. The rolling mill can roll the steel strip with the thickness of 2-3mm into semi-tubes in different diameters. The thickness of the wall of the semi-tube rolled by the rolling mill is evenly changed with the curvature thereof, and the semi-tube shows no folding. The finished product semi-tube has the advantages of low rigidity and good flexibility, and can be smoothly and spirally wound or directly laid on a cylindrical shell of a device while arranging the device.

Owner:HEBEI INSTALLATION ENG

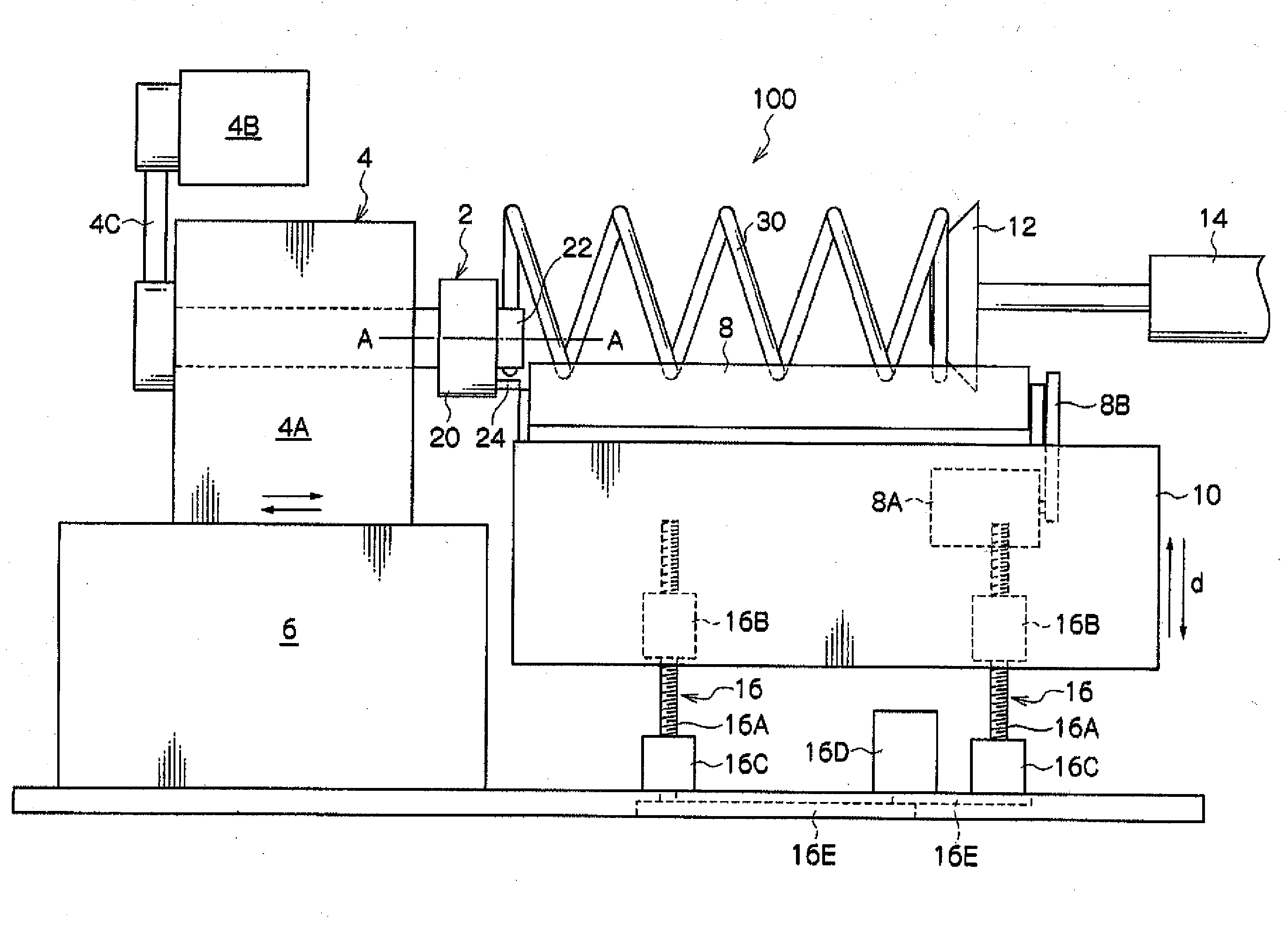

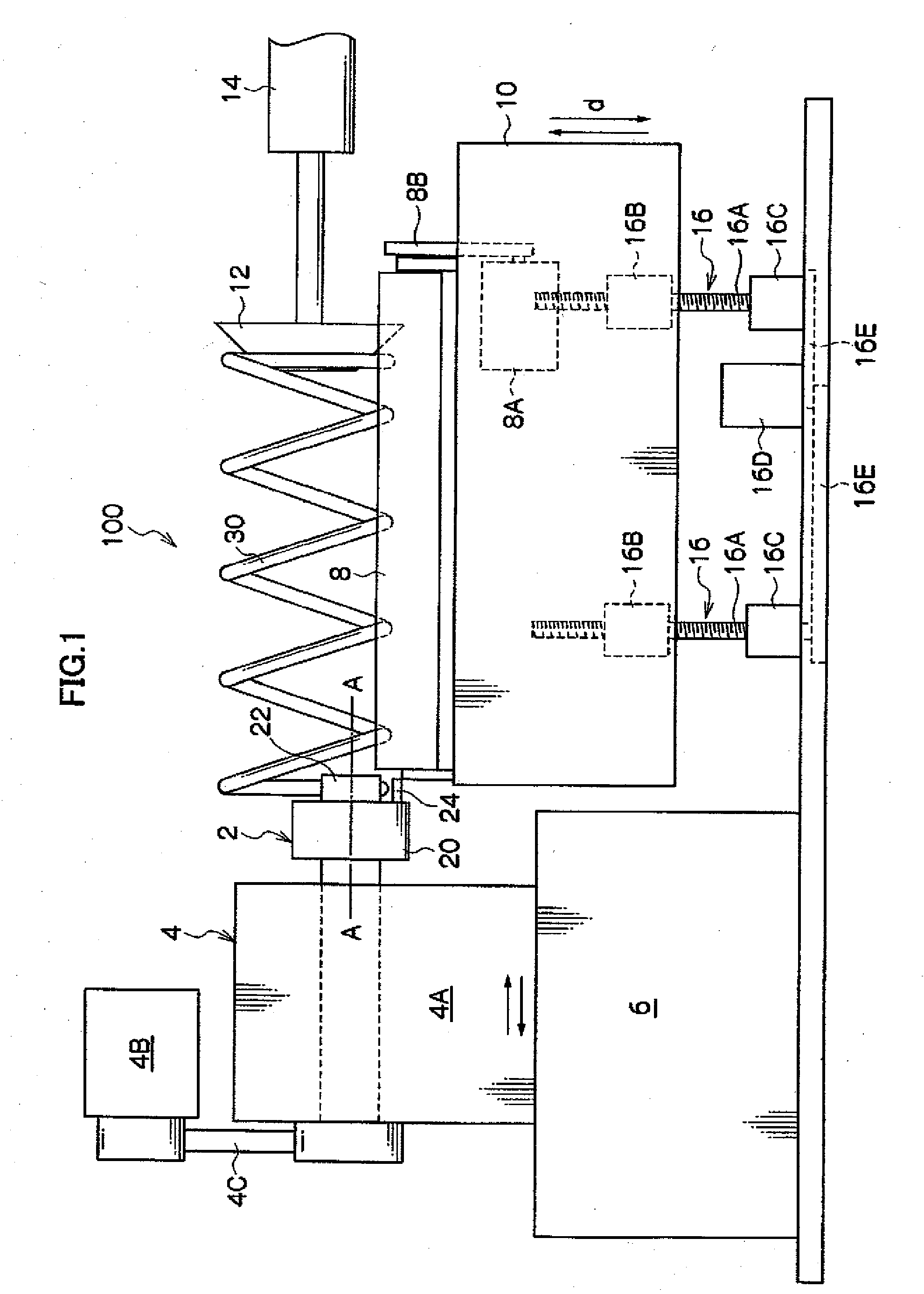

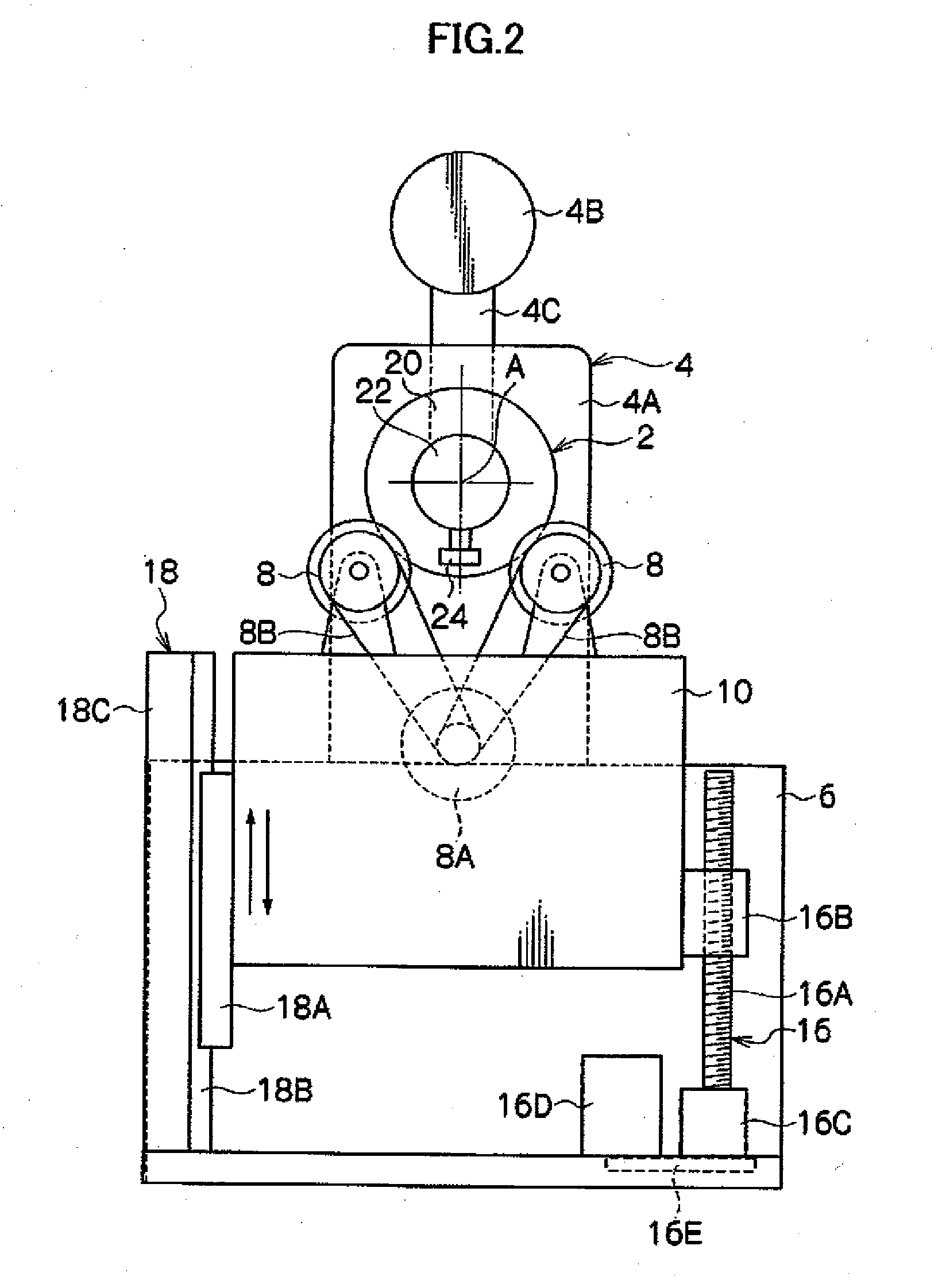

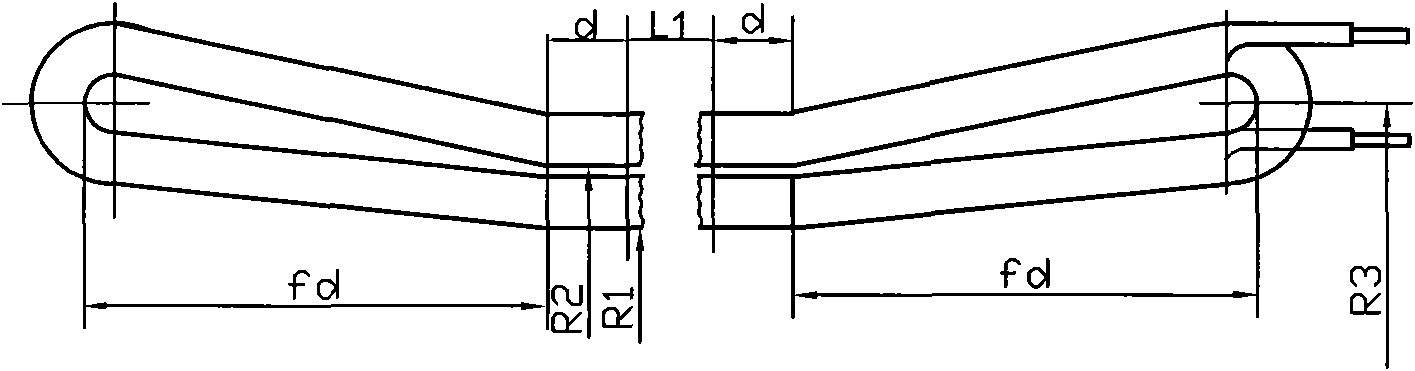

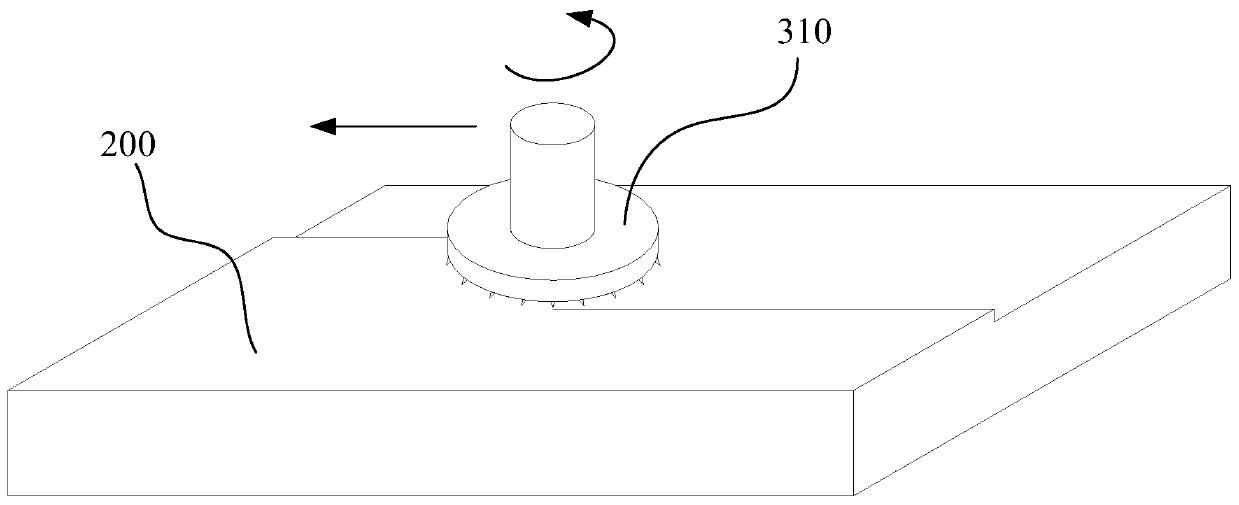

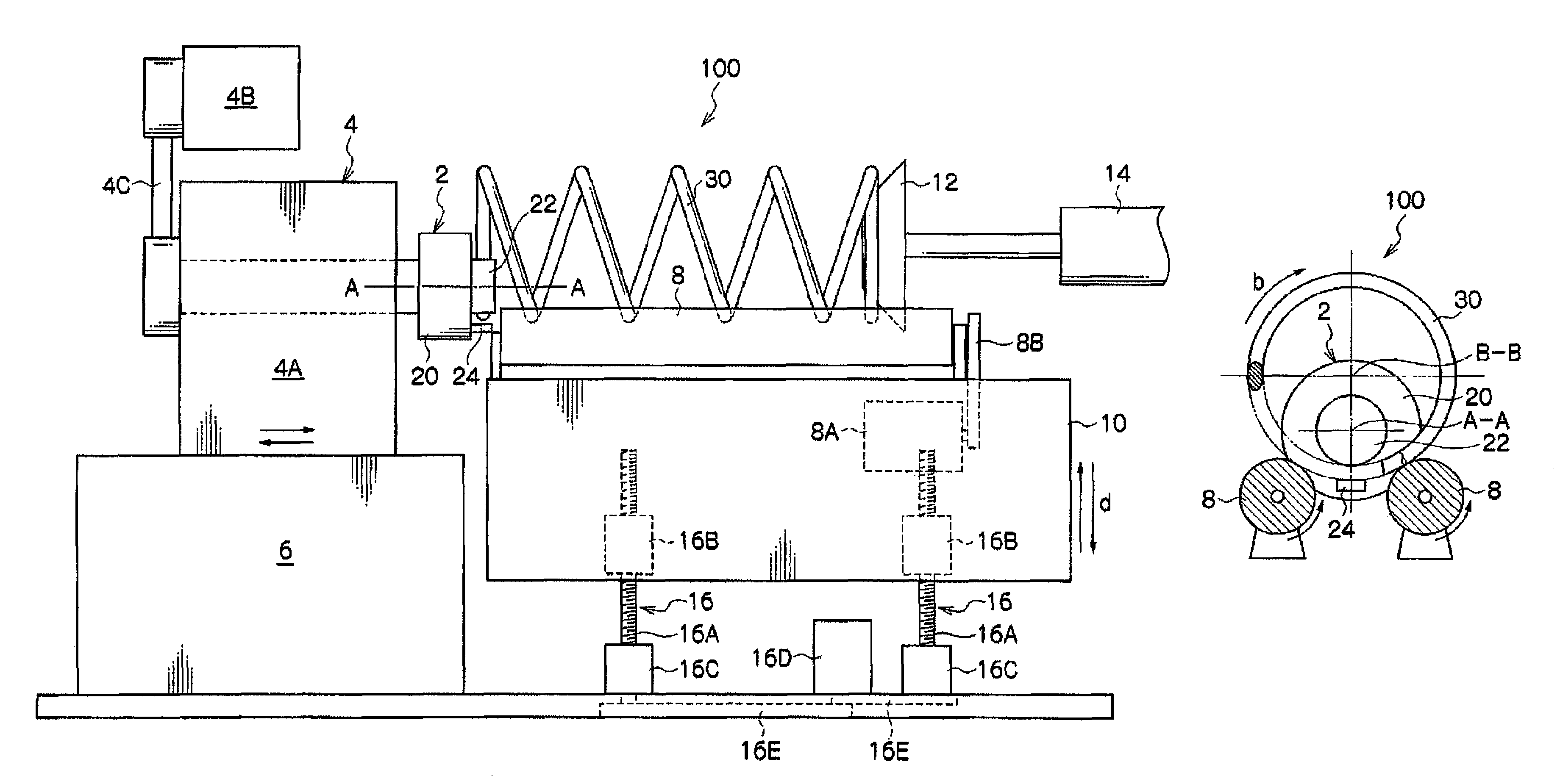

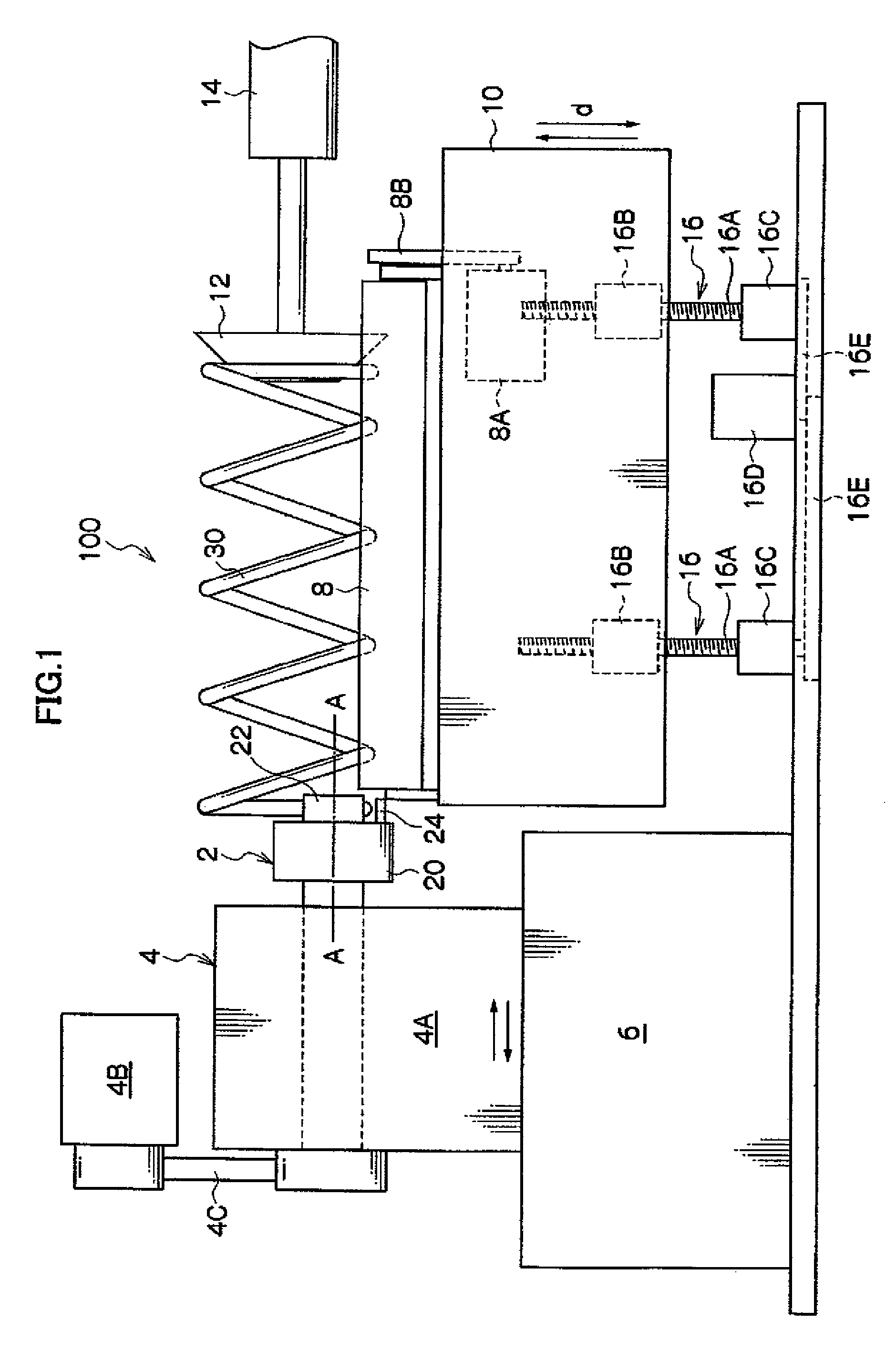

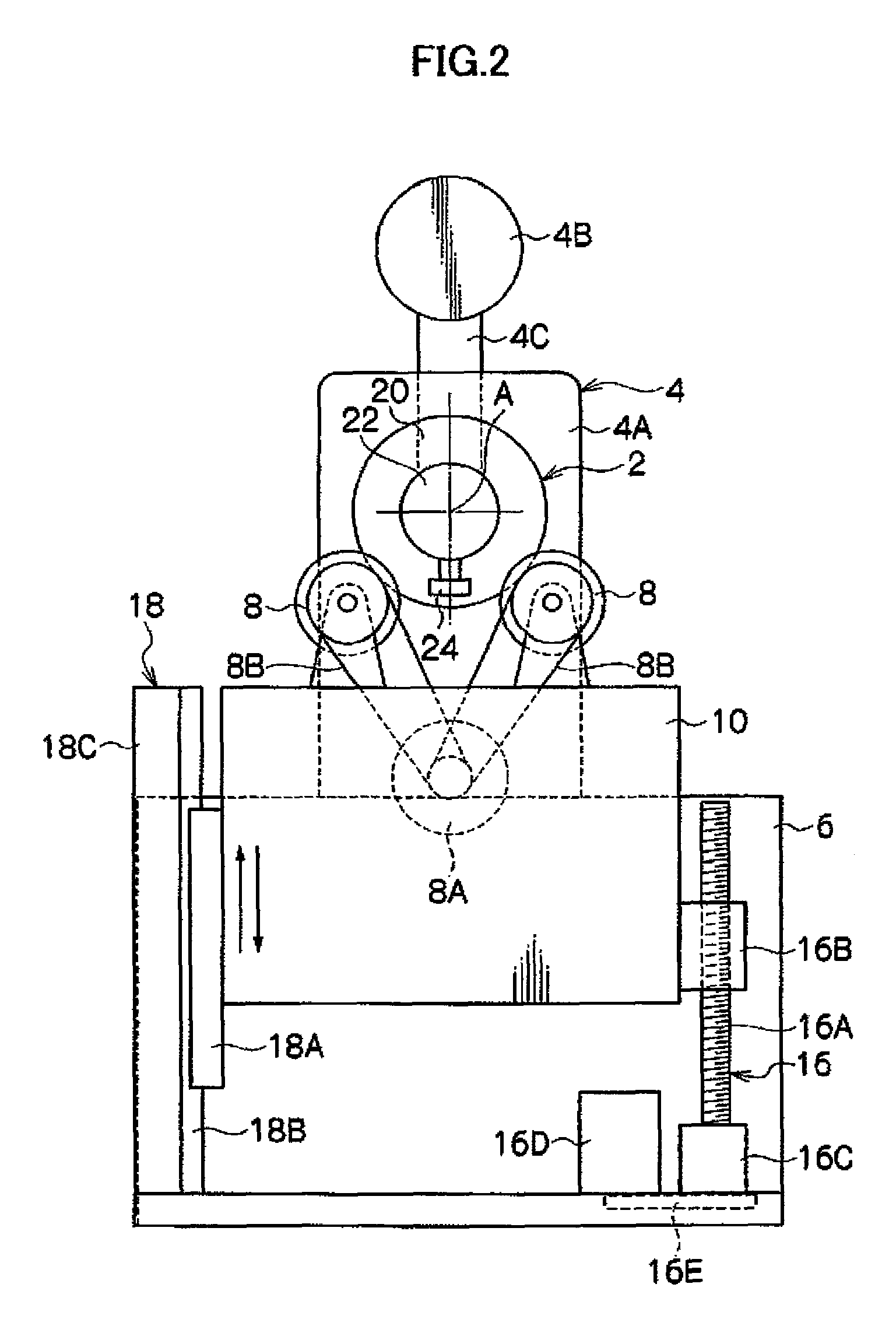

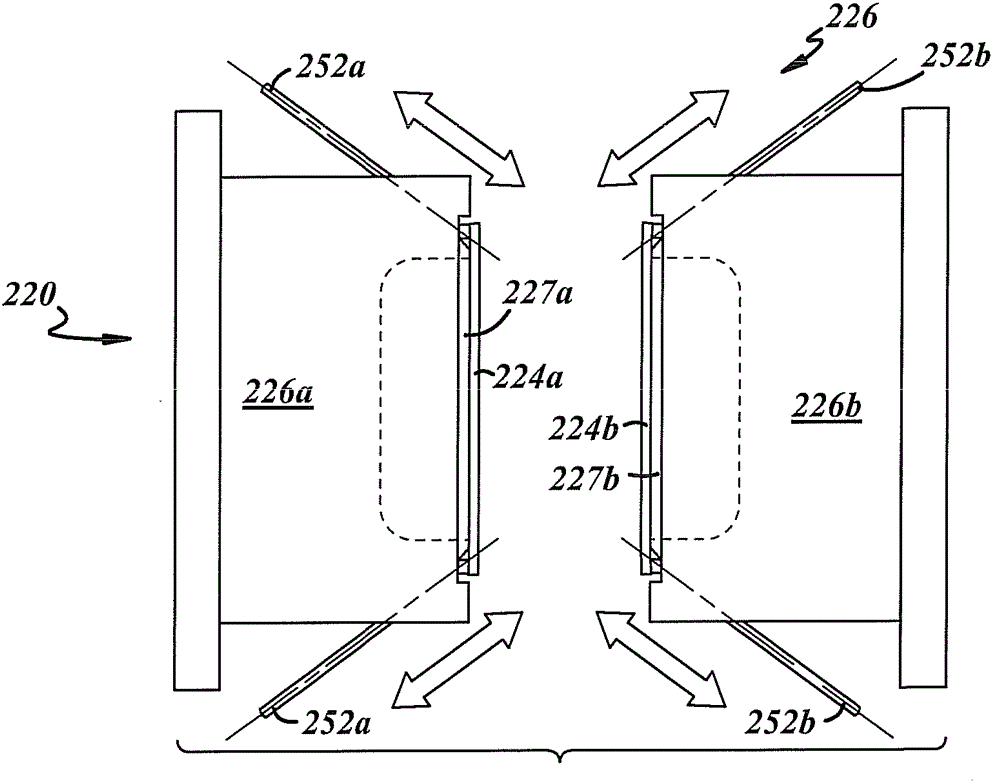

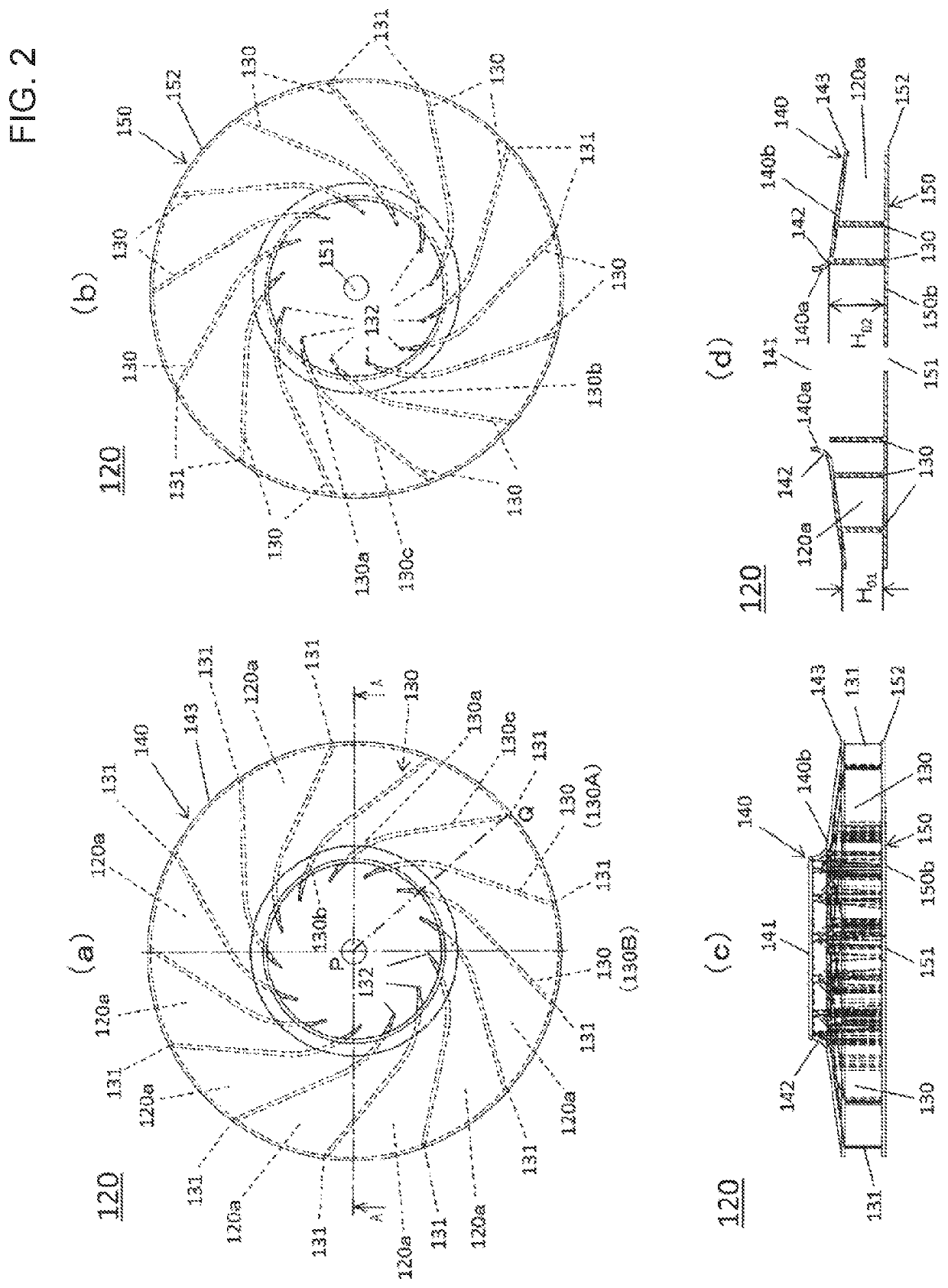

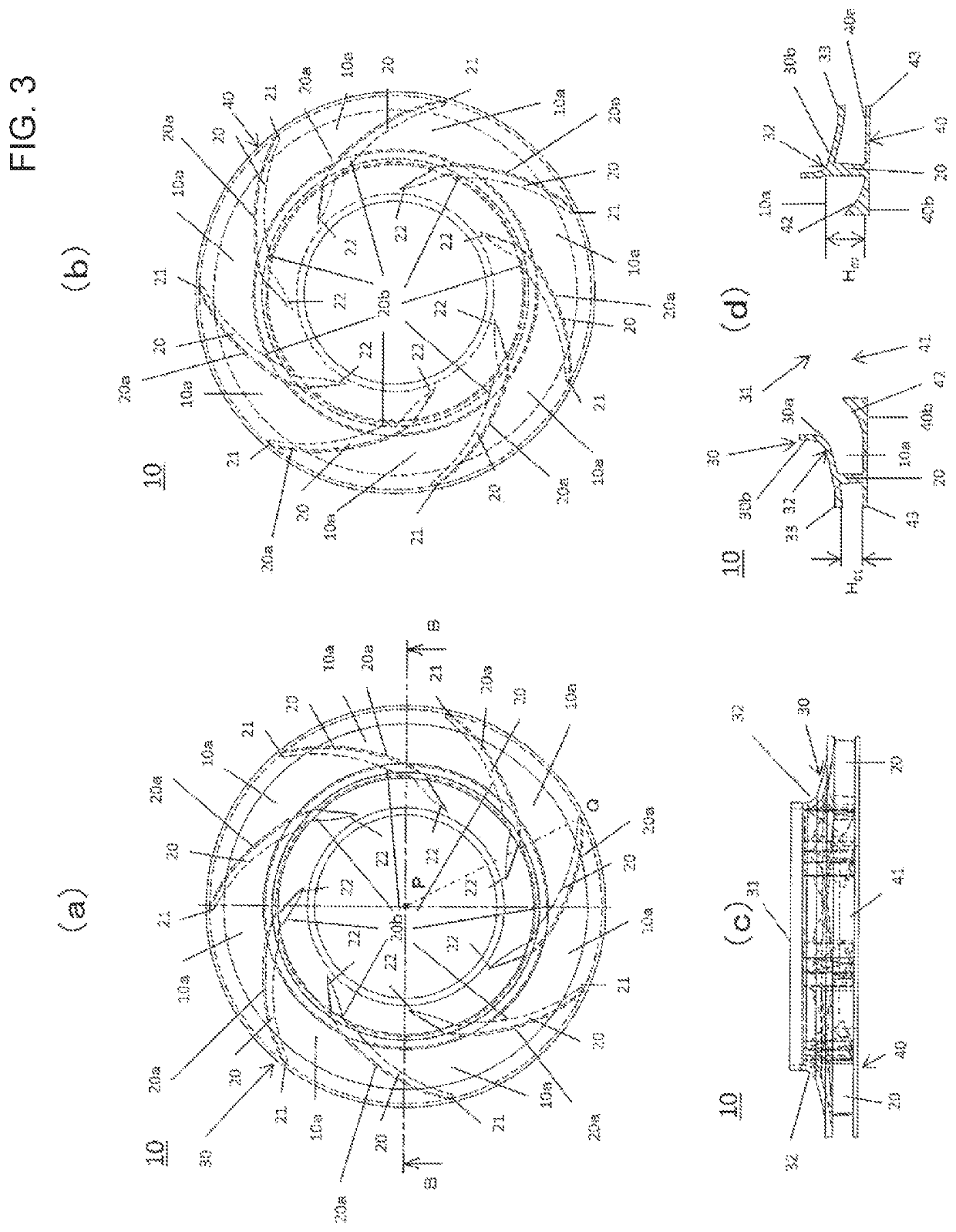

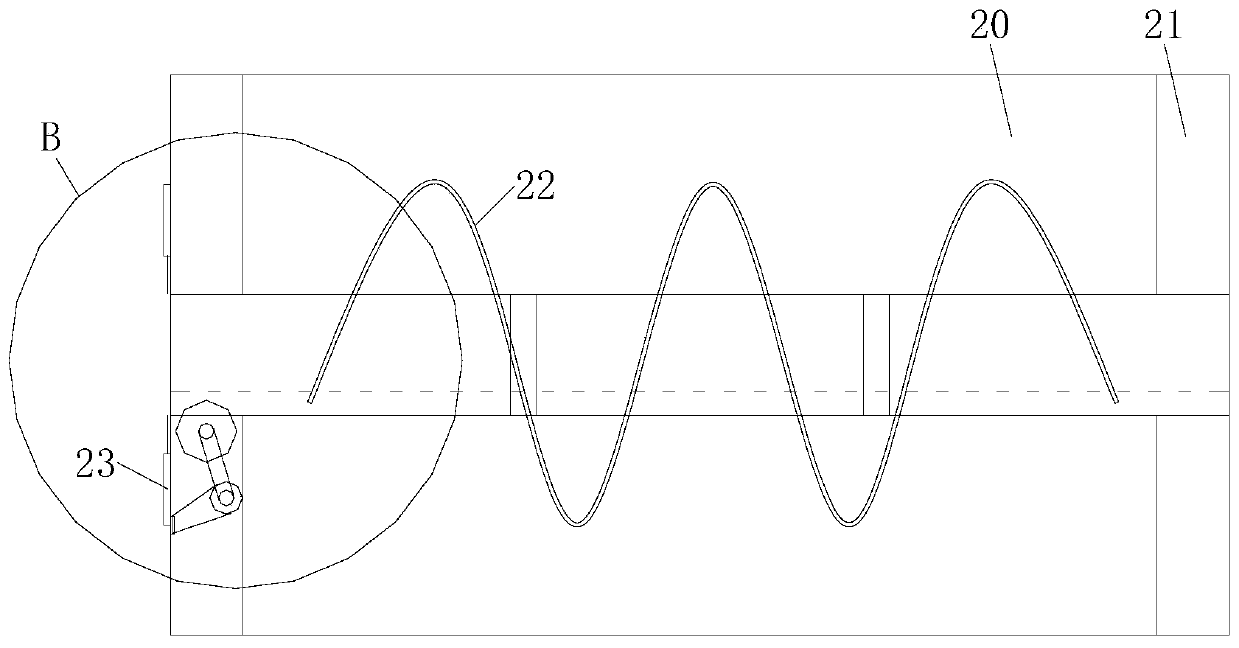

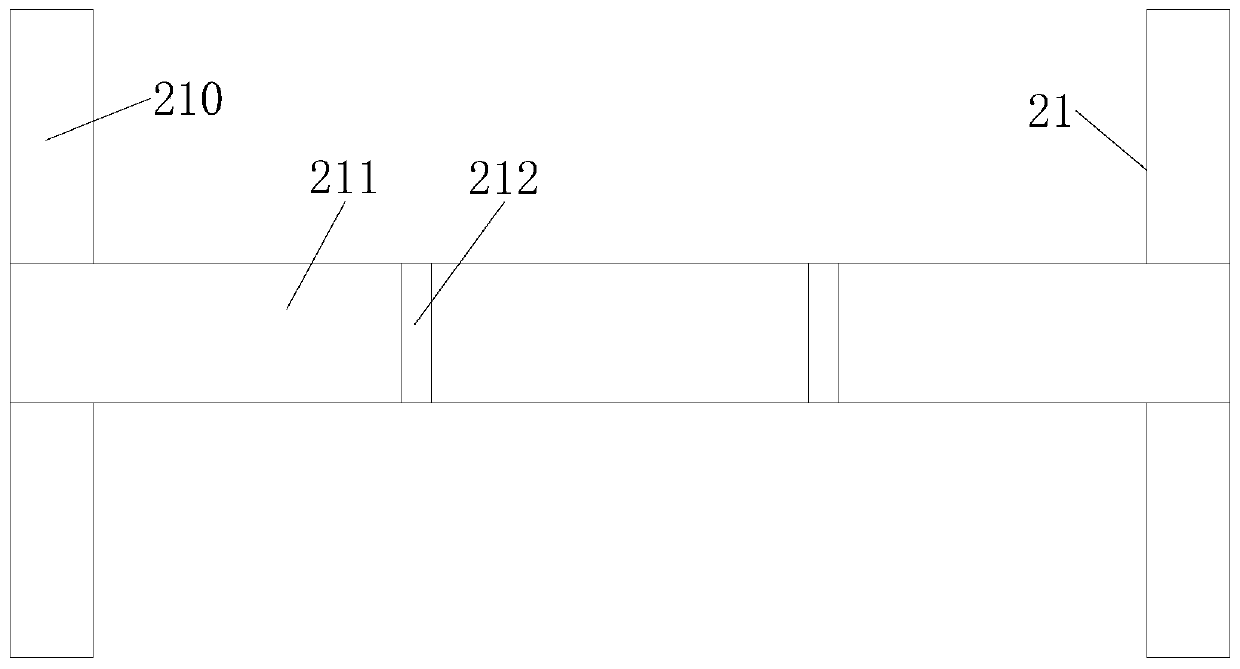

Device and method for forming end of coiled spring

ActiveUS20090283173A1Increase productivityShorten the timeWire springsSprings/dampers manufactureCoil springEngineering

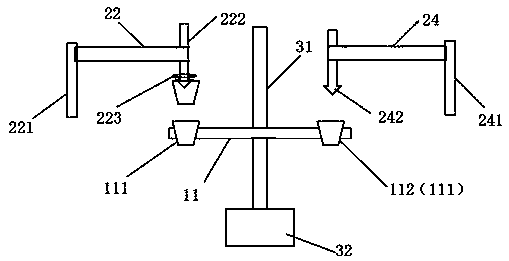

A coil spring end forming apparatus is provided that includes a pair of horizontally disposed parallel rollers 8; a mandrel 22; a stopper 20 that is provided adjacent to the circumferential surface of the mandrel 22 and is moved up or down and rotated integrally with the mandrel 22; a clamp jig 24 that is provided so as to be movable toward or away from the mandrel 22 and that holds a semi-formed spring 30 in cooperation with the mandrel 22, and a pusher 12 for pushing the semi-formed spring 30 toward the stopper 20, wherein in a state in which the axis of the mandrel 22 is positioned between the axes of the parallel rollers 8 and the semi-formed spring 30, a clamp portion 2 holds the semi-formed spring 30 at the inner side of a triangle formed by the axes of the parallel rollers 8 and the semi-formed spring 30 and rotates around the axis along the winding direction of the semi-formed spring 30 to form a pigtail portion at one end of the semi-formed spring 30, and a coil spring end forming method is further provided.

Owner:MITSUBISHI STEEL MFG CO LTD

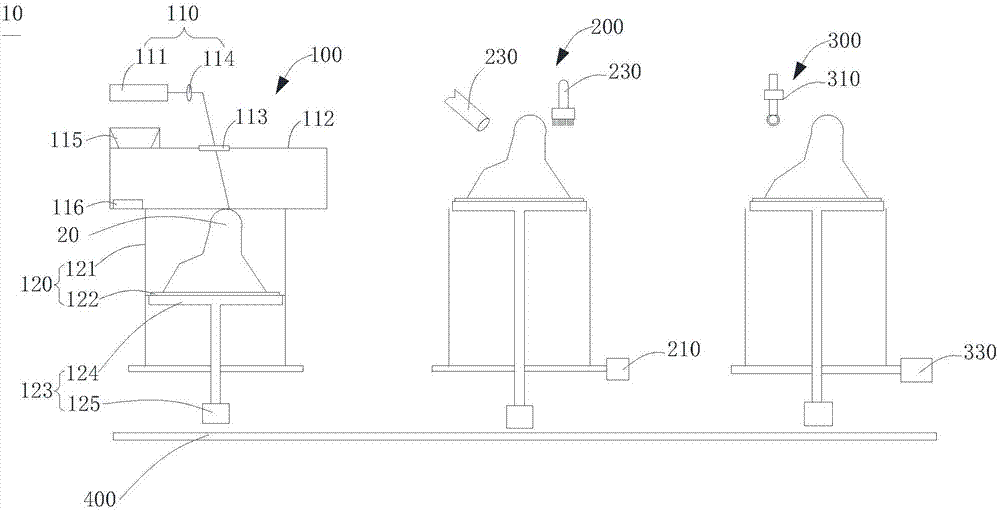

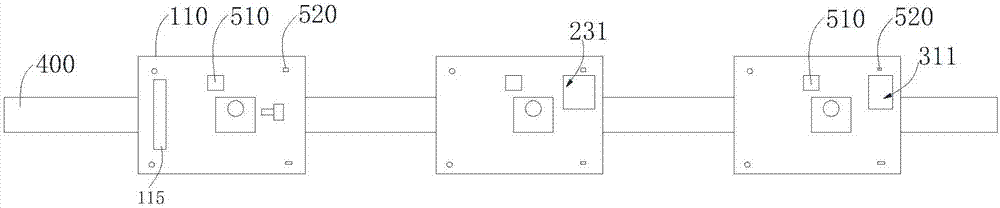

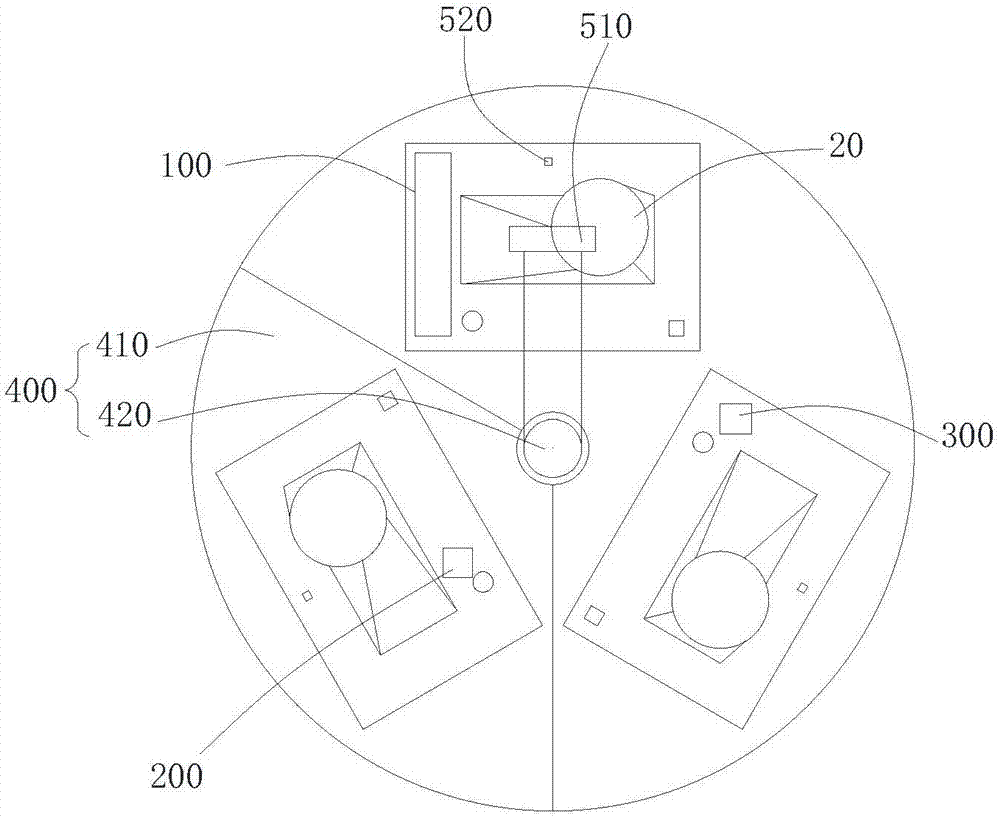

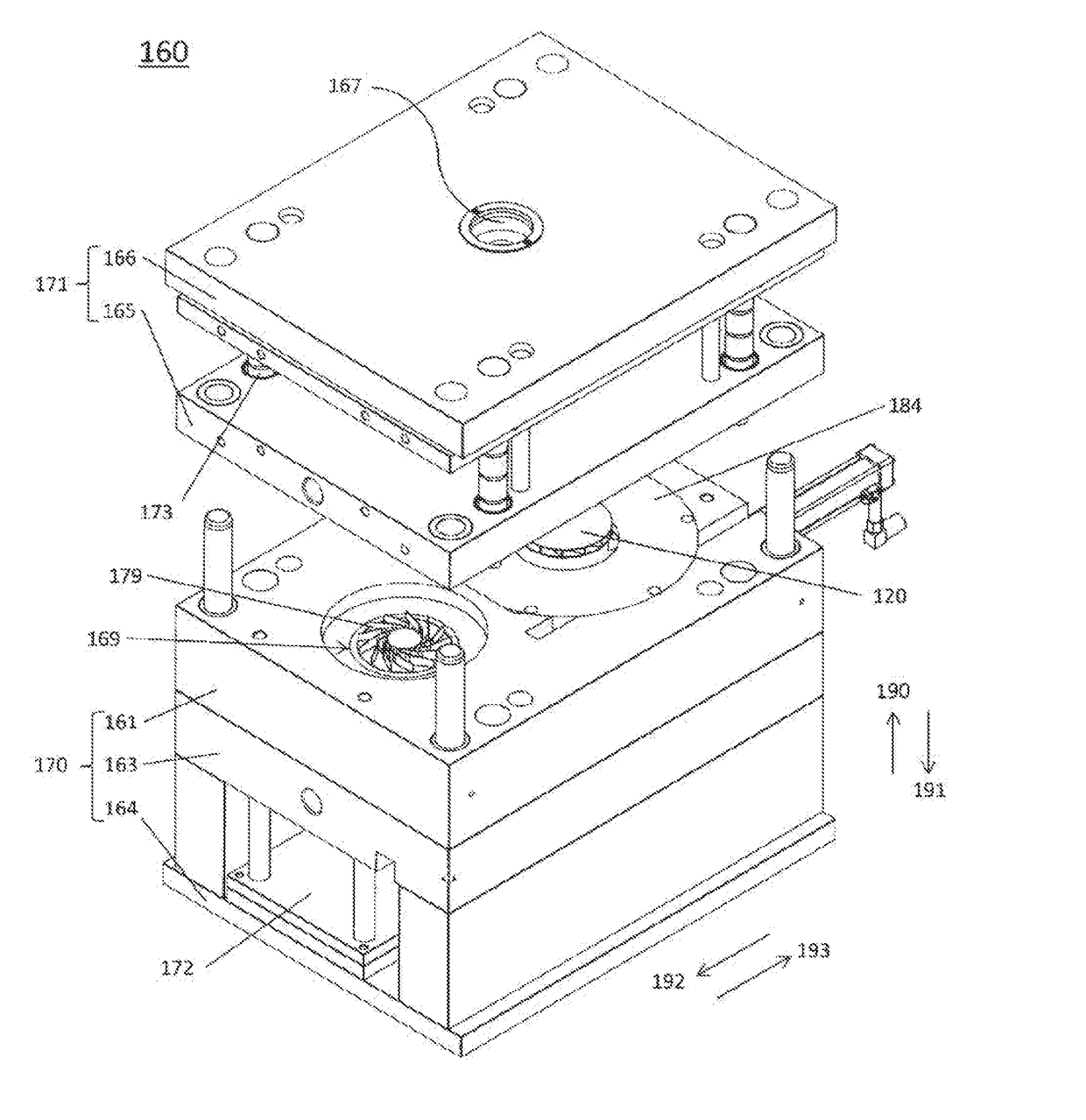

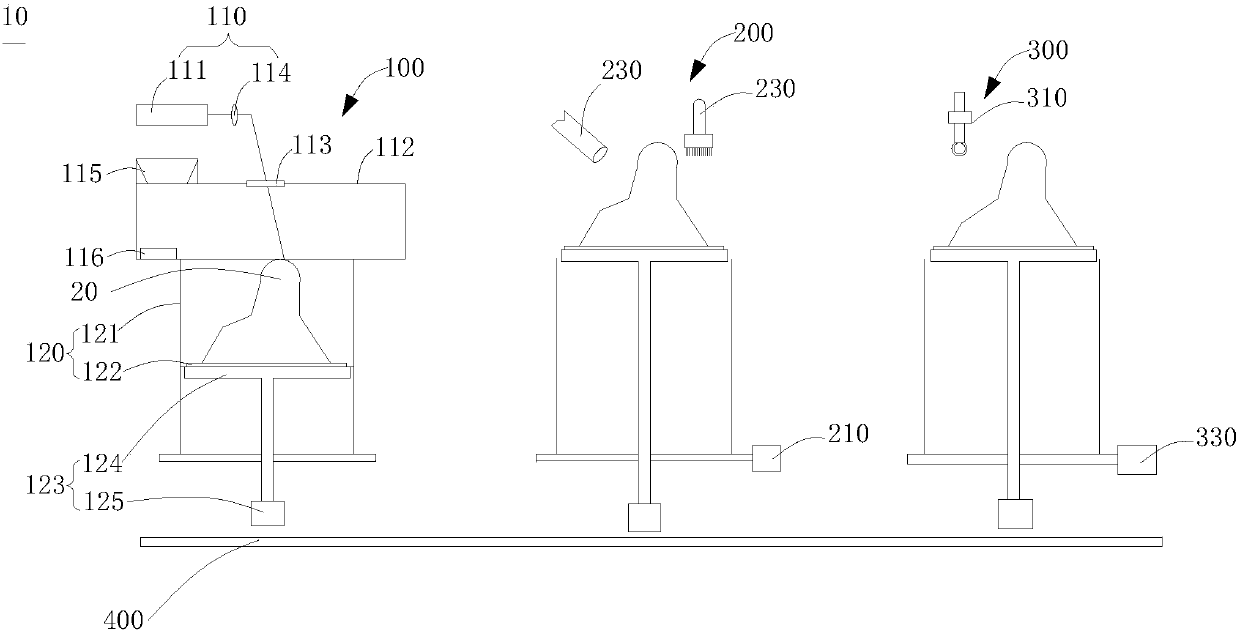

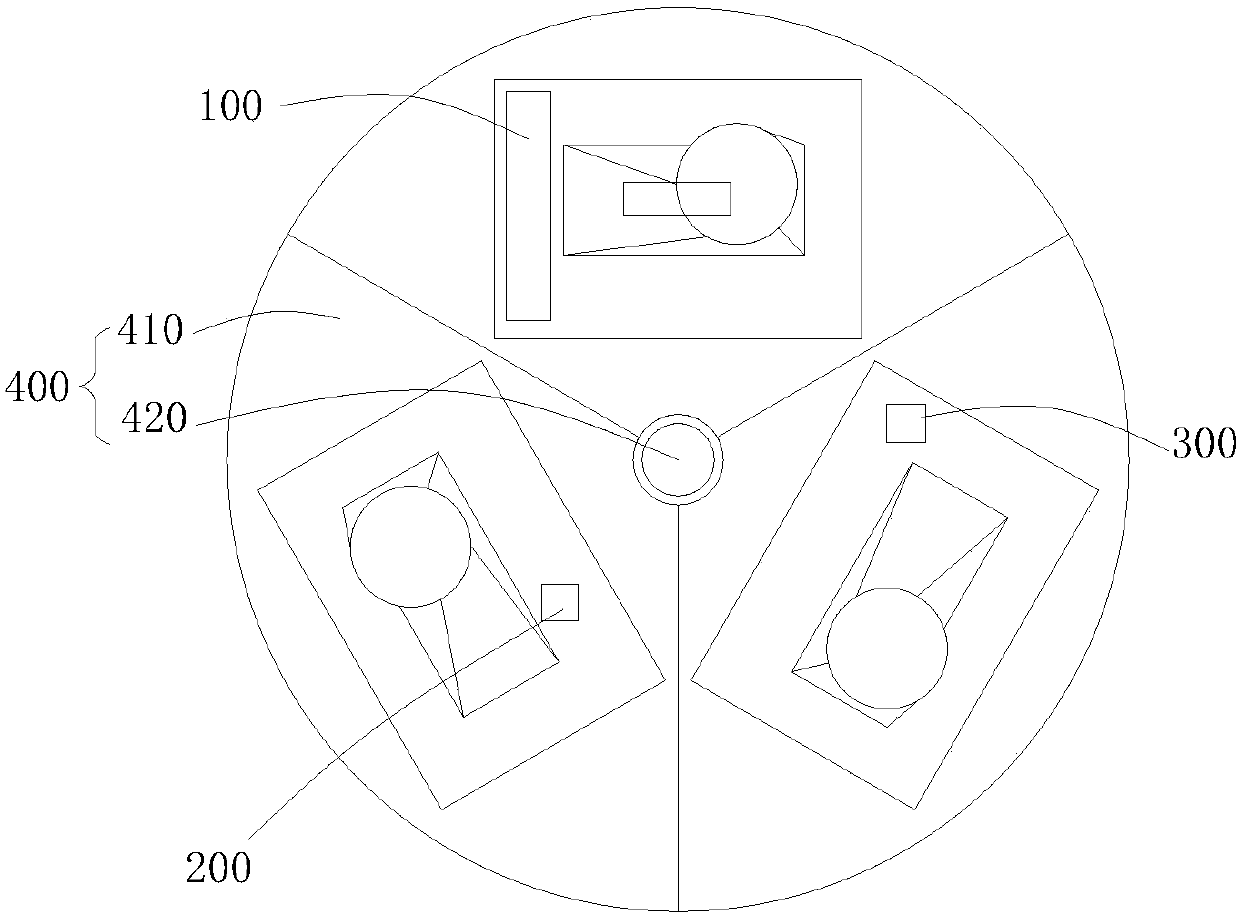

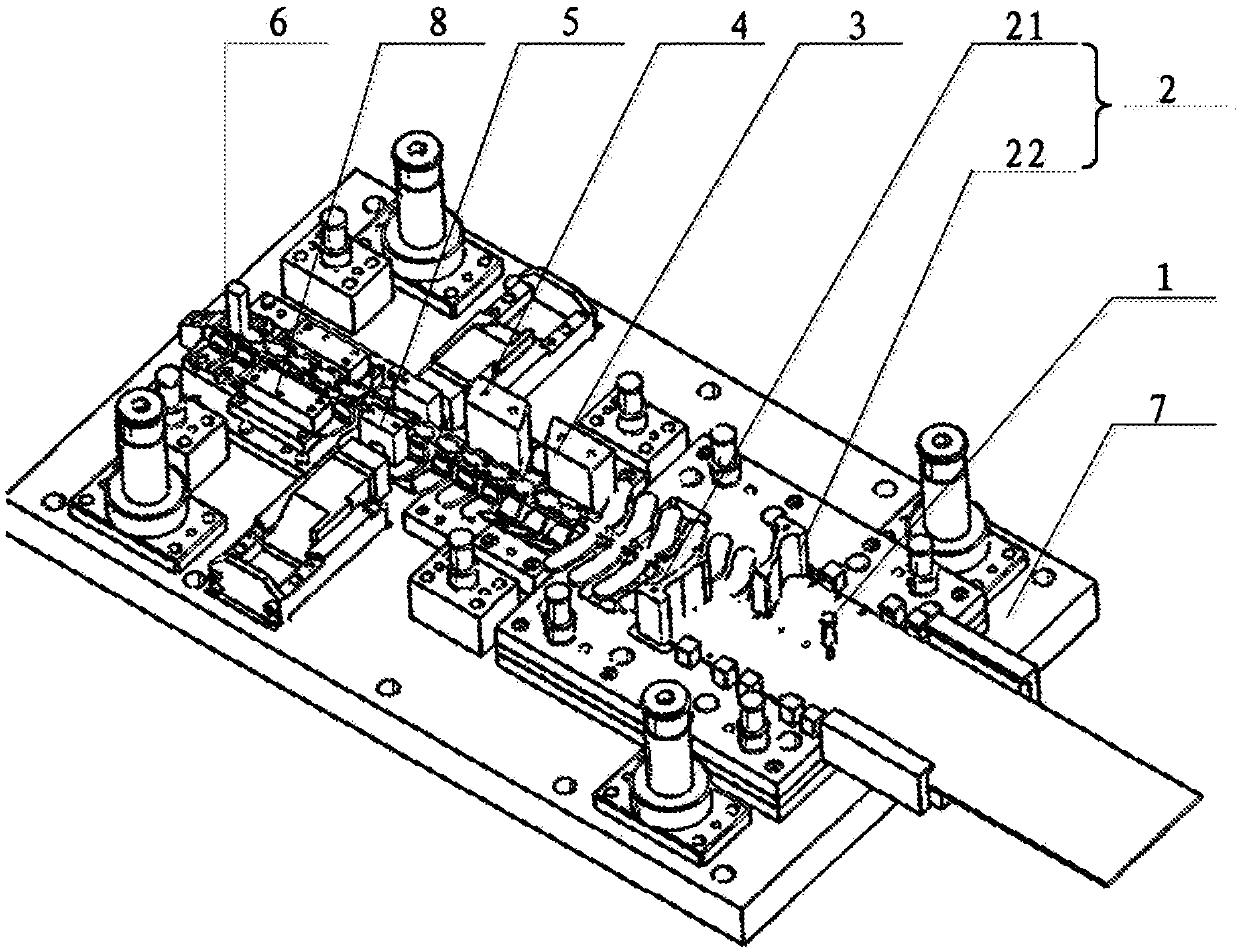

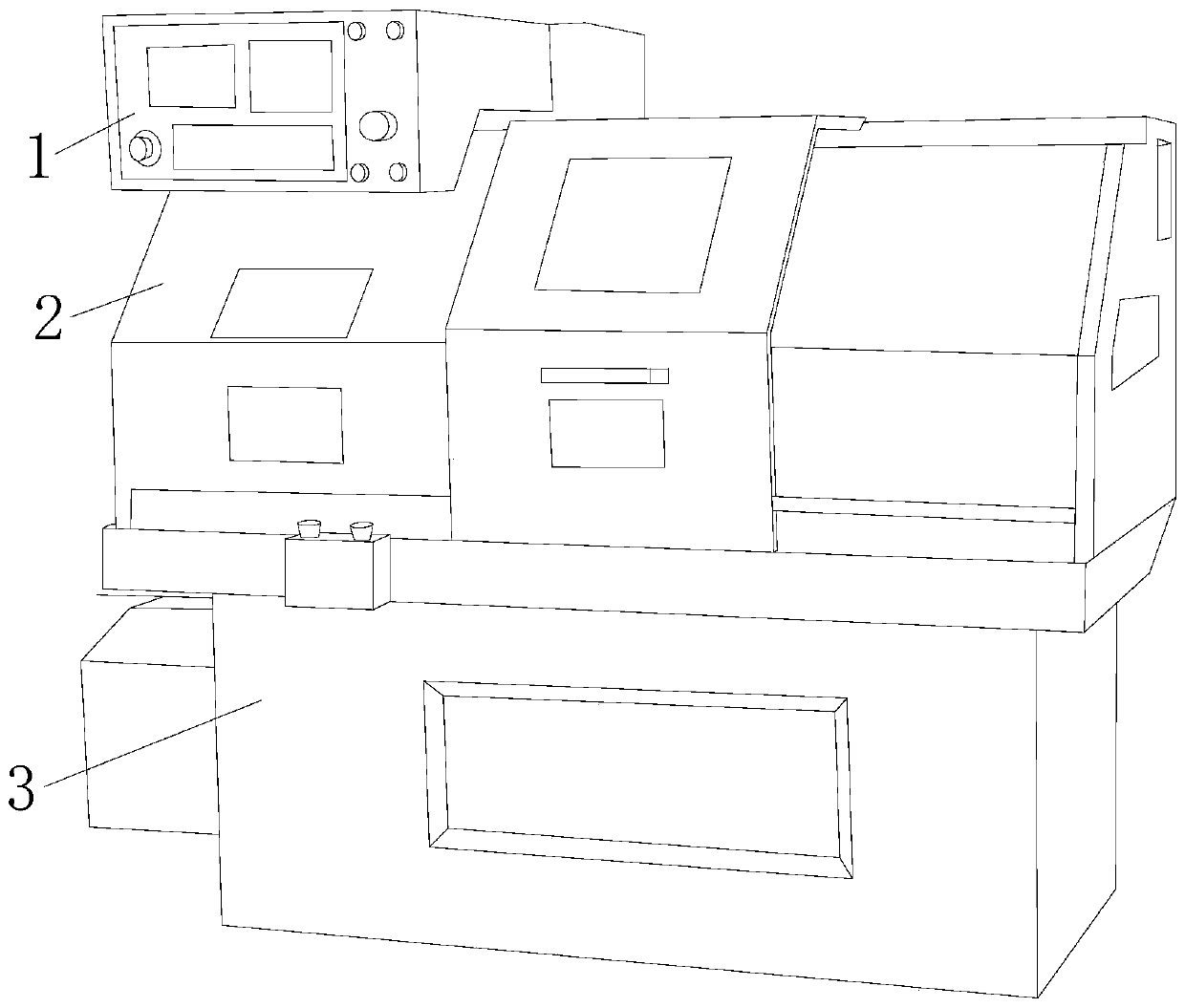

Additional and subtraction material composite processing equipment

InactiveCN107415236AImprove applicabilityImprove processing efficiencyAdditive manufacturing apparatus3D object support structuresEngineeringMaterials processing

Additional and subtraction material composite processing equipment comprises an additional material manufacturing device, a cleaning device, a subtraction material processing device, a transfer device and a positioning device. The additional material manufacturing device comprises an energy source mechanism and a forming mechanism; the forming mechanism comprises a forming cavity and a forming substrate arranged in the forming cavity; the energy source mechanism is used for forming and repeated forming of powder on the forming substrate; the transfer device is used for transferring the forming mechanism and workpieces positioned on the forming substrate between two optional workstations of an additional material manufacturing workstation, a cleaning workstation and a subtraction material processing workstation; the cleaning device is used for cleaning the workpieces on the forming substrate; the subtraction material processing device is used for processing the workpieces on the forming substrate; and the positioning device is used for positioning the forming substrate. Subtraction material processing can be added between semi-formed workpieces and formed workpieces of additional material manufacturing, subtraction material processing on inner and outer surfaces of the semi-formed workpieces can be implemented accurately in time, the applicability and processing efficiency of the formed workpieces are improved, positioning is accurate, and the quality of the formed workpieces is controllable.

Owner:HUNAN FARSOON HIGH TECH CO LTD

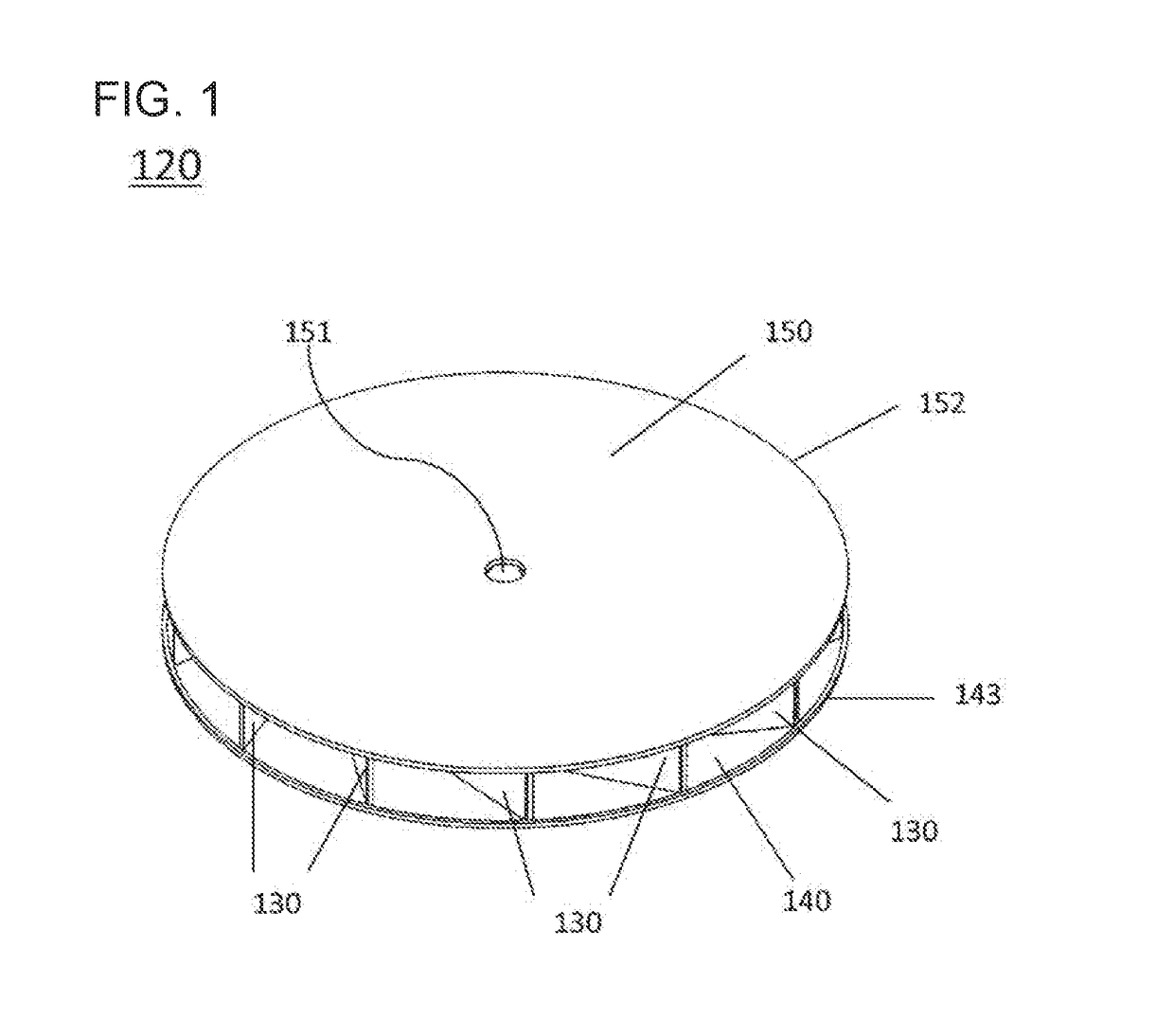

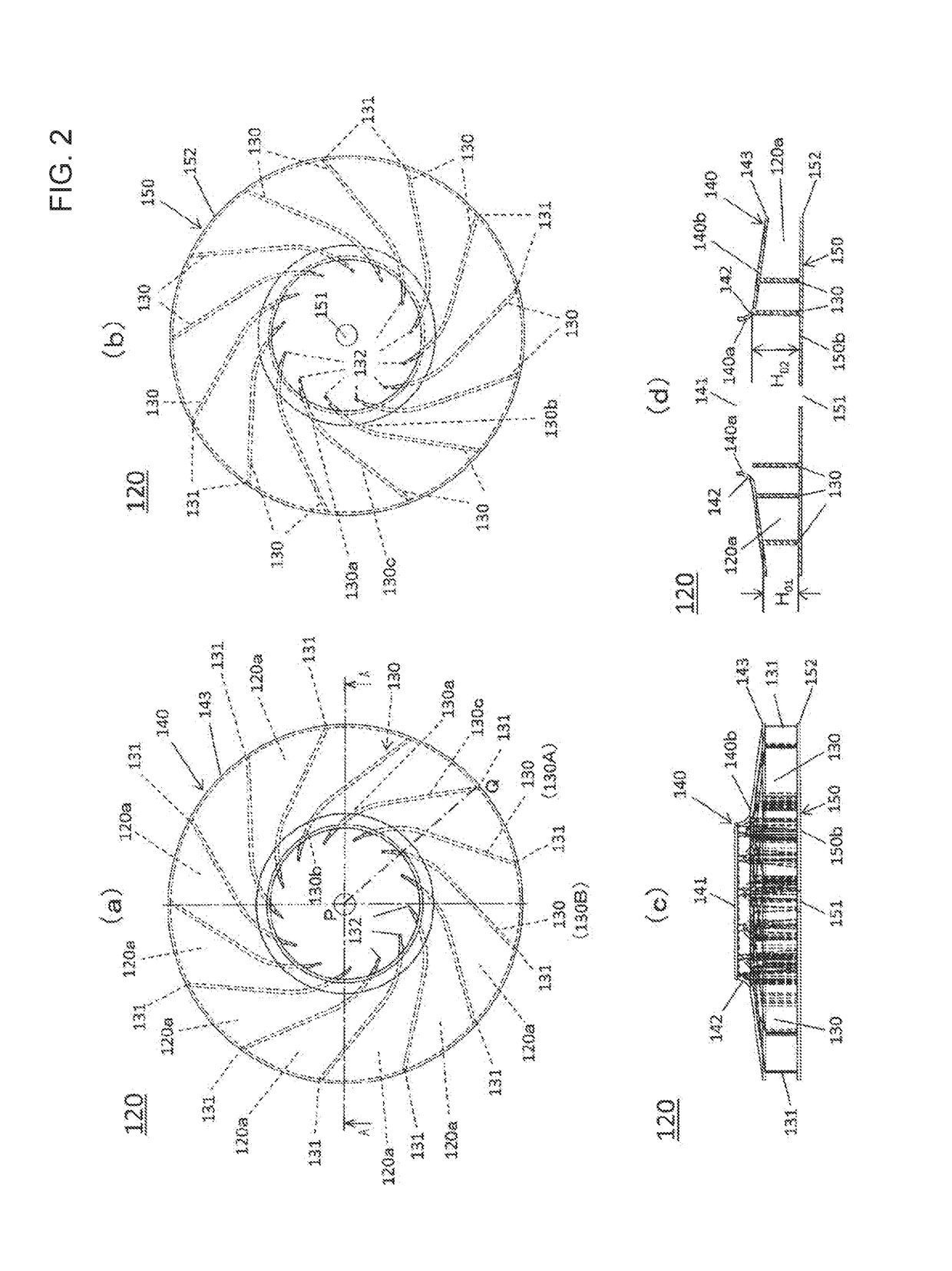

Manufacturing method and manufacturing device for resin fan

Owner:MATSUDAKANAGATAKOGYO CO LTD

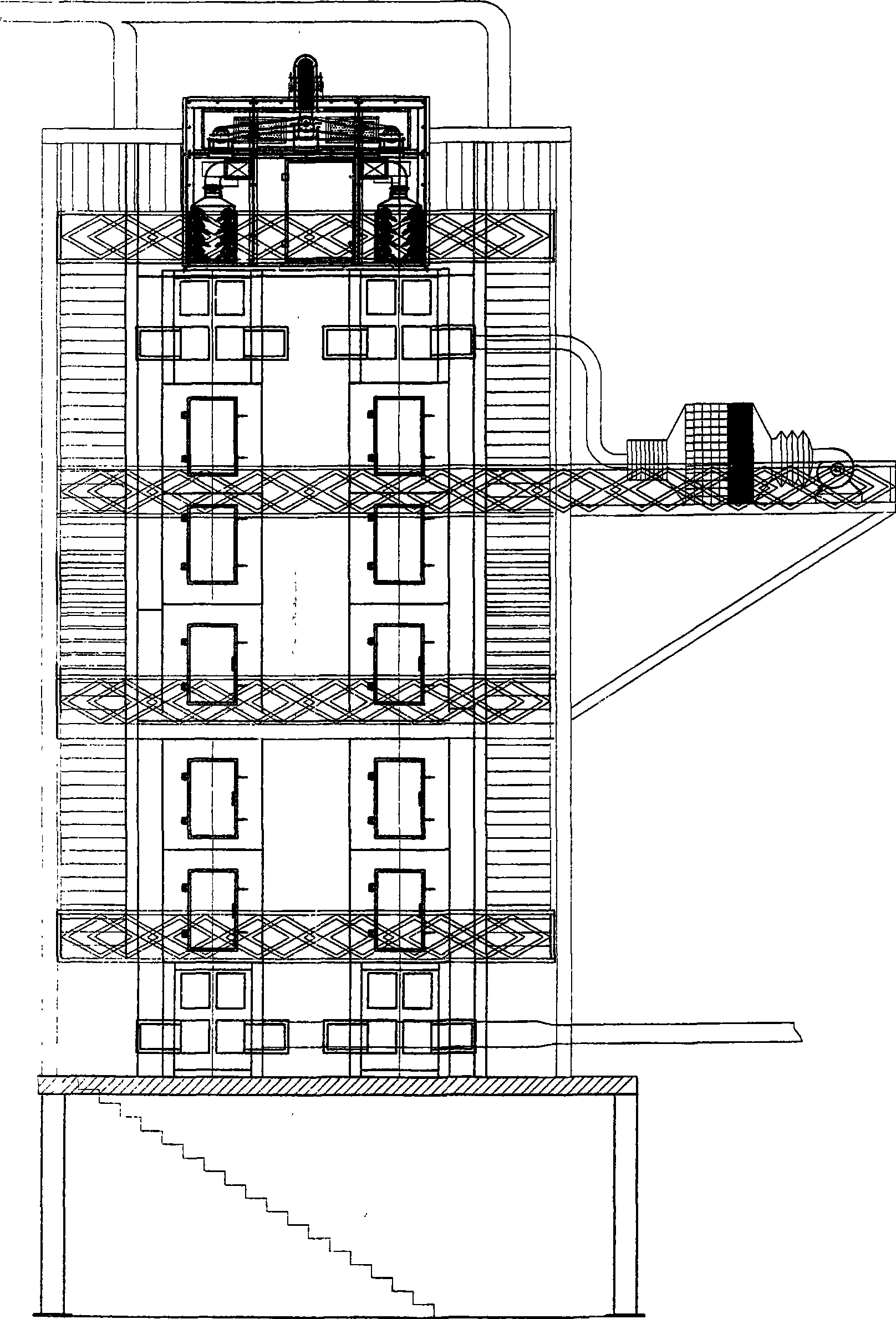

Vertical far infrared radiation impregnation drying production line

InactiveCN101476247AIndex uniformFlat surfaceDrying solid materials with heatPretreated surfacesProduction lineWinding machine

The invention provides a vertical type far infrared radiation dipping drying production line, which consists of a unwinding machine and tension control, a cloth receiving machine, a front material storing machine, a front traction and tension control, a back-coating machine, a dipping machine, a hot gas heat exchanger, an upward oven, a cold wind chamber, a downward oven, a rectifying machine, a traction machine, a trimming machine, a rear material storing machine, a tension control and a winding machine. The drying form is vertical to unify the dipping amount of the left and right side of the dipped material; the dried material runs in the drying oven, cooling the dipping material by wind while it is semi-formed, descending on through a roller with temperature adjustable cold water passing through, re-drying for final complete solidification and shaping. The invention aims to provide a production equipment to make the dried material to have uniform dipping indexes in the left, middle and right parts, and a leveling surface.

Owner:NANTONG KAIDI AUTOMATIC MACHINERY

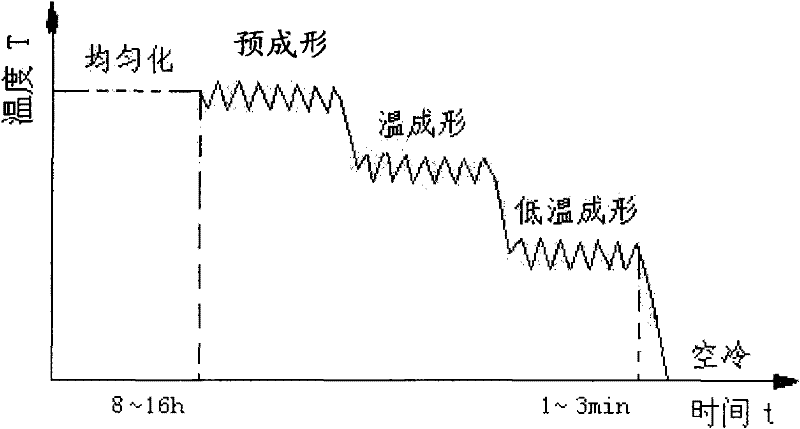

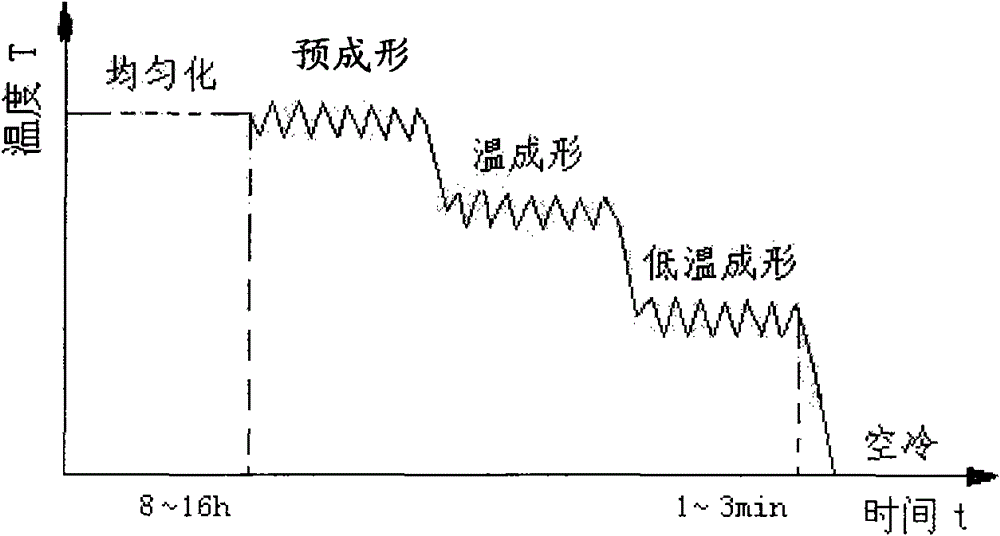

Magnesium alloy construction member step temperature forming method

InactiveCN102172750ARealize comprehensive utilizationImprove performanceMetal-working apparatusThermal energyHeating furnace

The invention provides a magnesium alloy construction member step temperature forming method. The method comprises the process route, namely homogenizing, preforming, warm forming and low temperature forming and is characterized in that: 1, in the stage of homogenizing and preforming, homogenizing is carried out in a heating furnace, and upsetting and preforming are directly carried out by utilizing a blank homogenizing temperature, wherein the thermal temperature of preforming is 380 minus or plus 10 DEG C; 2, in the stage of warm forming, warm extrusion forming is carried out on the preformed upsetting blank in a mould, wherein the warm forming temperature is 340 minus or plus 10 DEG C; and 3, in the stage of low temperature reshaping, low temperature reshaping is carried out on a semi-formed blank obtained after the warm forming is finished in the mould again, wherein the low temperature reshaping temperature is 300 minus or plus 10 DEG C. By adopting the method provided by the invention, the problems that high temperature forming performance of a magnesium alloy is low and the magnesium alloy can not be formed at a low temperature are solved, coordination and uniform of forming and toughening on the magnesium are realized, and product performance is improved; and energy sources are saved, the process is simplified, and waste heat of homogenizing is utilized to directly carry out subsequent plastic deformation, thus the process is simplified, the thermal energy is effectively utilized, and the production cost is reduced.

Owner:ZHONGBEI UNIV

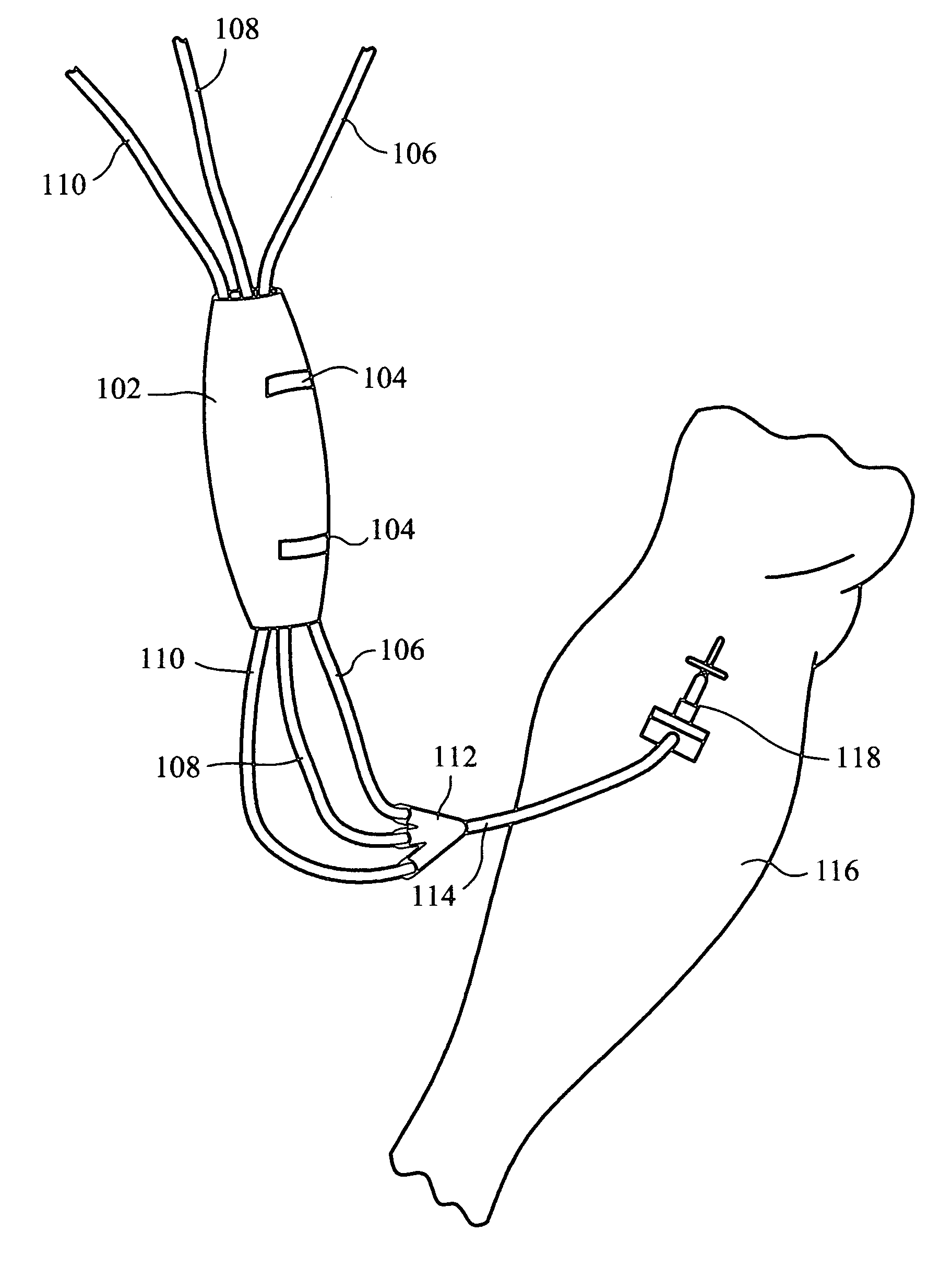

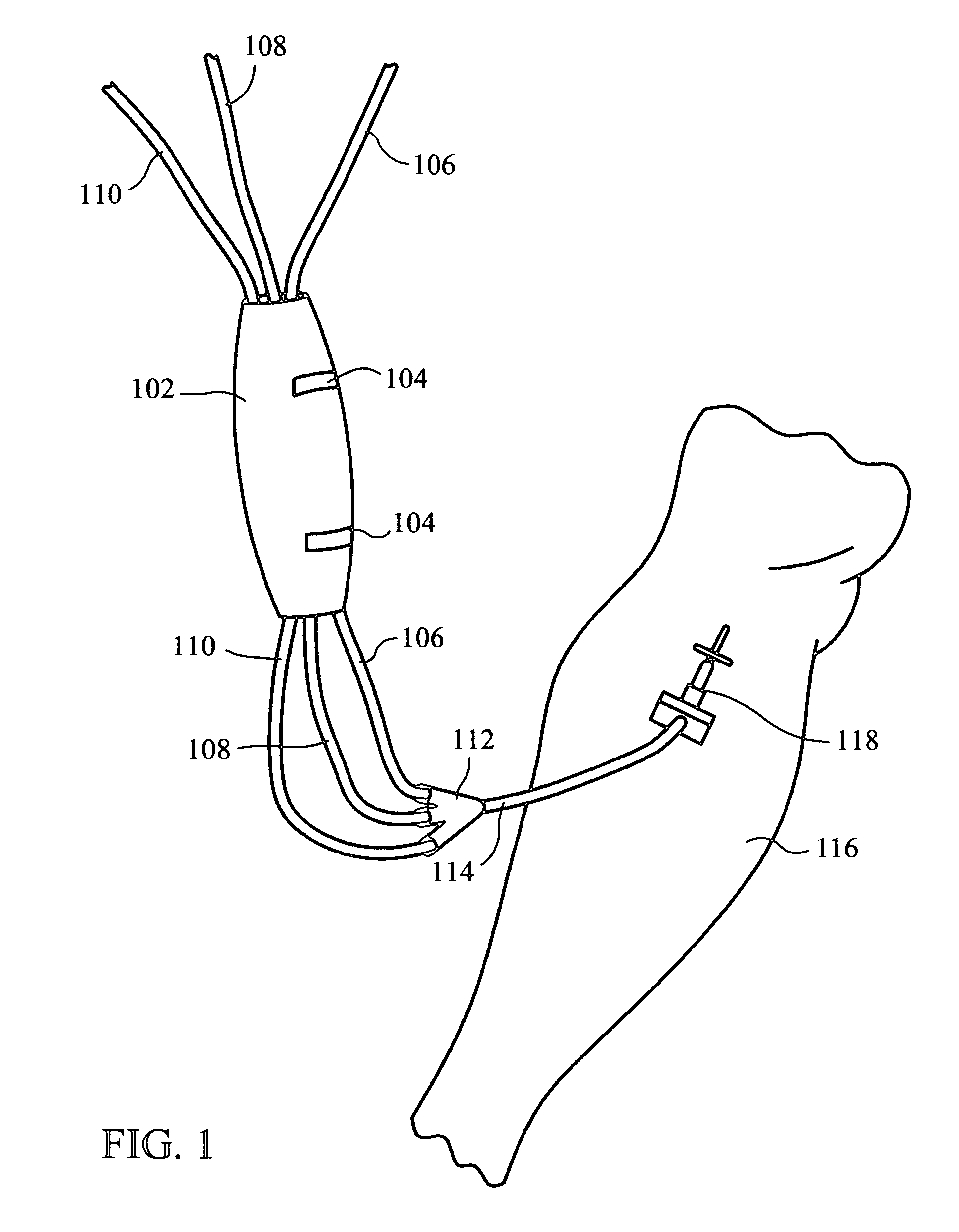

Intravenous tubing protector and support system

InactiveUS20070078401A1Patient comfortPrevent the tangling of the tubingInfusion needlesSupporting systemIntravenous tubing

The present invention relates to an intravenous tubing protector or organizing wrap support designed to consolidate multiple numbers of tubing by encircling all the tubing together. More particularly, the device would organize and prevent the tangling of intravenous tubing and may be made up of a flat, elongate, flexible and elastic strip of material of sufficient length to encircle at least two or more numbers intravenous tubing or may be made of a fitted and potentially predetermined width and length of semi-formed material that would retain its shape around the tubing but yet be comfortable to the patient. Attached to the ends of the flexible material that may be overlapped would likely include one or more fastener assemblies constructed of respective engagable upper and lower respective pluralities of resilient engaging elements which are separated by a distance sufficient to ensure that the captured loop of the intravenous tubing remains unkinked.

Owner:SERVOSS SUSAN J

Stator core with winding for medium-sized low-voltage variable-frequency motor

InactiveCN101860096AImprove power factorImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsFrequency changerSlot insulation

The invention relates to a stator core with a winding for a medium-sized low-voltage variable-frequency motor, which comprises semi-formed windings, semi-open slot stator punched plates, a bottom pad, a slot insulation layer, a middle pad, a regulation pad, a slot wedge and a mounting slot, wherein the semi-formed windings are arranged at the two ends of the mounting slot; the slot insulation layer is arranged in the mounting slot; the bottom pad is placed on the bottom layer of the inner cavity of the slot insulation layer; a lower-layer stator coil formed by the semi-open slot stator punched plates is placed on the bottom pad; the middle pad is placed on the lower-layer stator coil; an upper-layer stator coil formed by the semi-open slot punched plates is placed on the middle pad; the regulation pad is placed on the upper-layer stator coil; the slot wedge is placed on the regulation pad; and the upper-layer and lower-layer coils are connected with the circuit of the semi-formed windings. The stator core improves the power factor and efficiency of the motor, reduces the capacity of the transducer, has high inter-turn insulation performance and improves the dv / dt value of the motor easily, thereby improving the reliability of the medium-sized variable-frequency motor.

Owner:WUXI ZHONGDA MOTORS

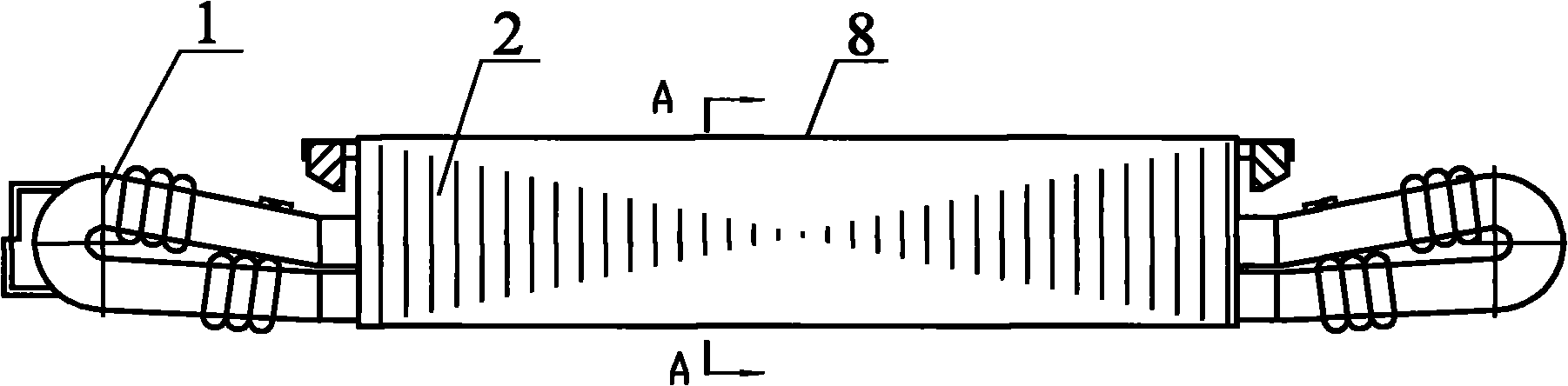

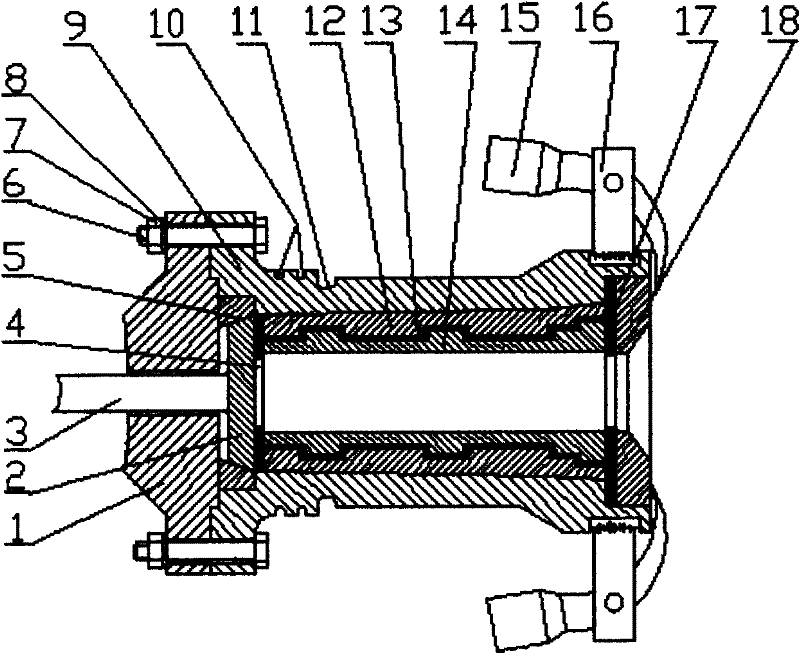

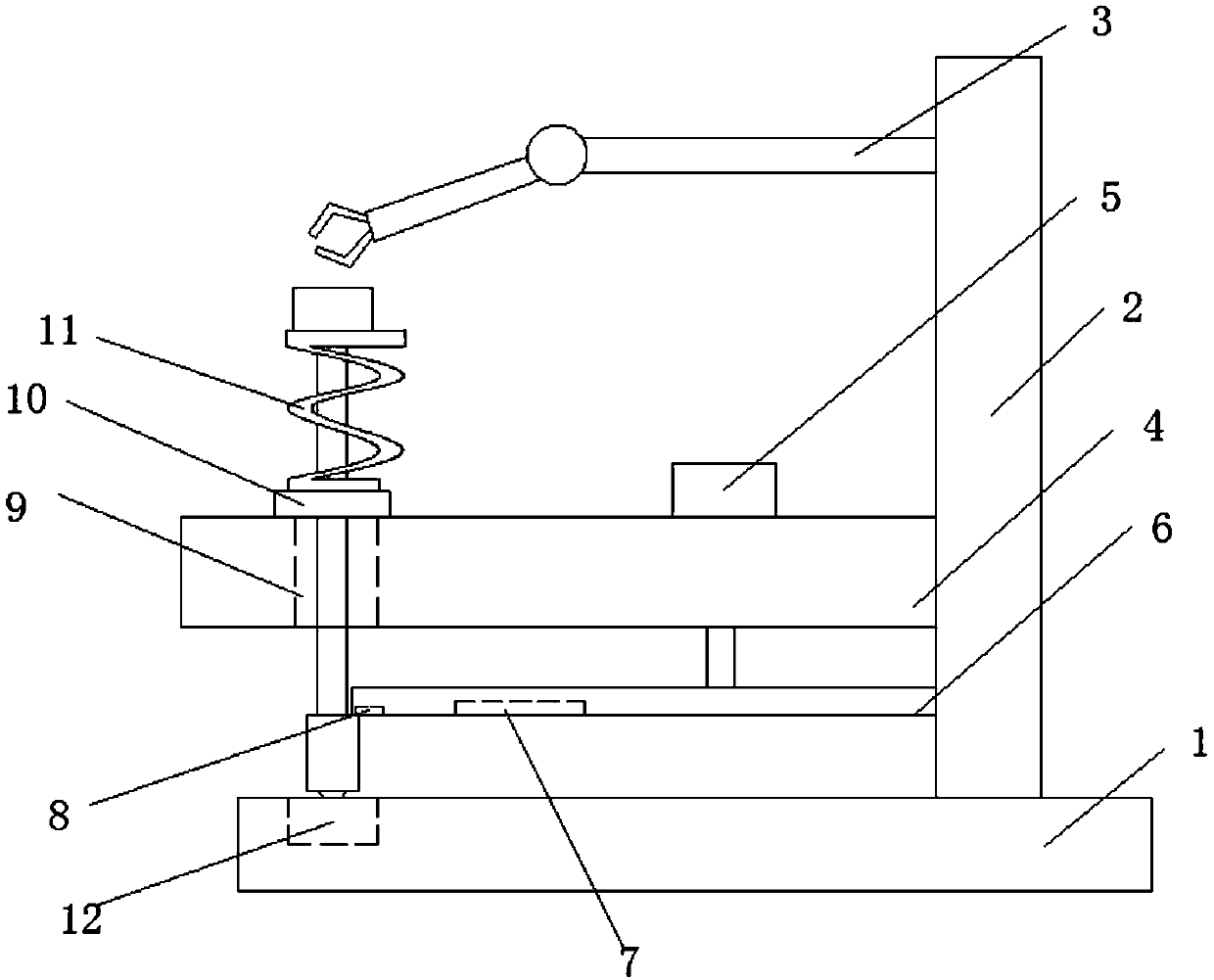

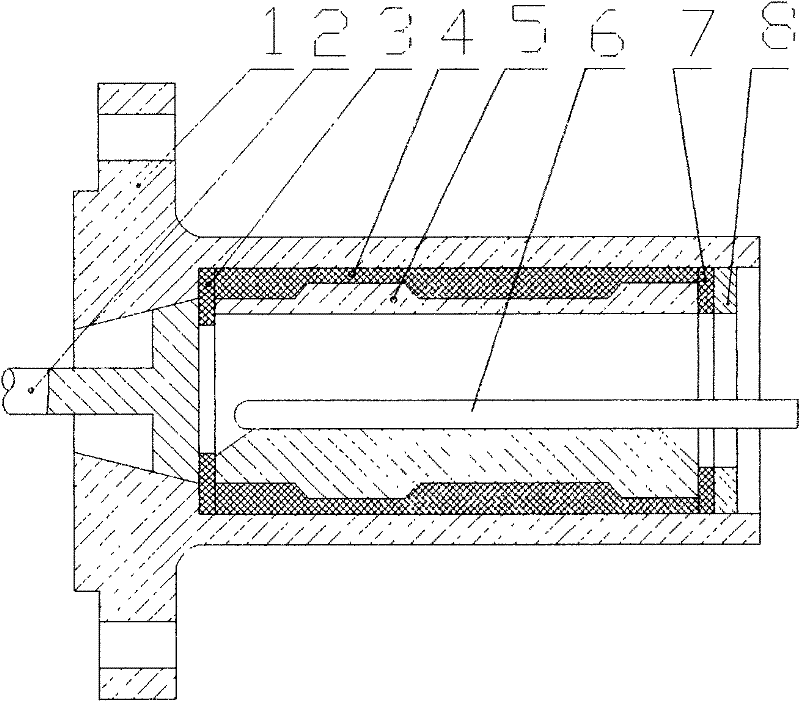

Semi-forming centrifugal casting mould

The invention discloses a semi-forming centrifugal casting mould. The casting mould comprises a main shaft flange plate (1), an ejector rod plate (2), a locating plate (5), a bolt (6), a nut (7), a casting mould (9), a sink (10), a water stop sink (11), an opening and forming sleeve (12), a fly hammer (15) and a blank cap (18), wherein the ejector rod plate (2) with an ejector rod (3) is installed at one end of the inner cavity of the casting mould (9) through the locating plate (5); the main shaft flange plate (1) is installed on the casting mould (9) through the bolt (6) and the nut (7); the opening and forming sleeve (12) is installed in the inner cavity of the casting mould (9); and the blank cap (18) is installed at the other end of the inner cavity of the casting mould (9) through the fly hammer (15). The semi-forming centrifugal casting mould is simple in structure, convenient to operate and capable of saving materials, reducing production cost and increasing the yield.

Owner:韦斌

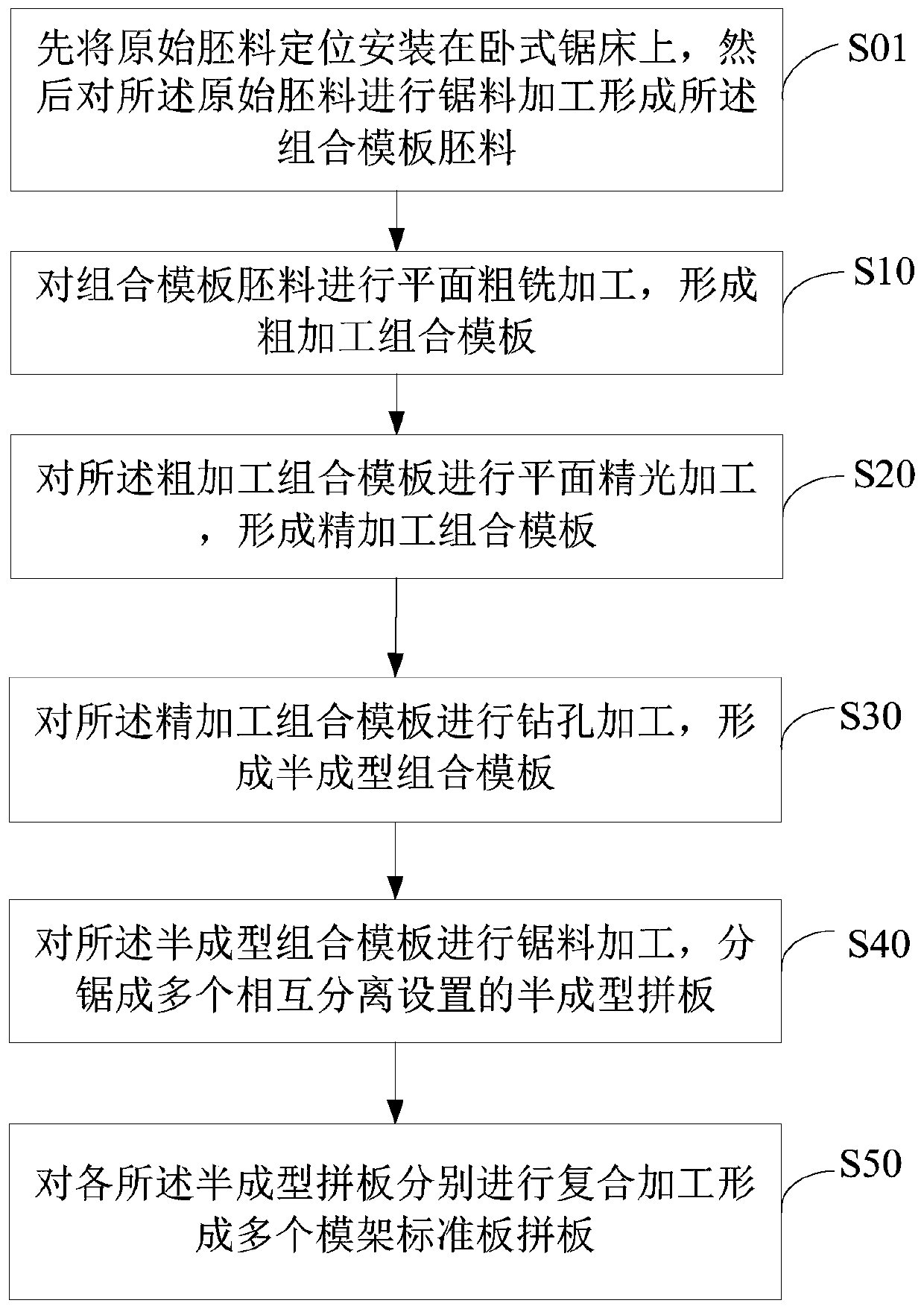

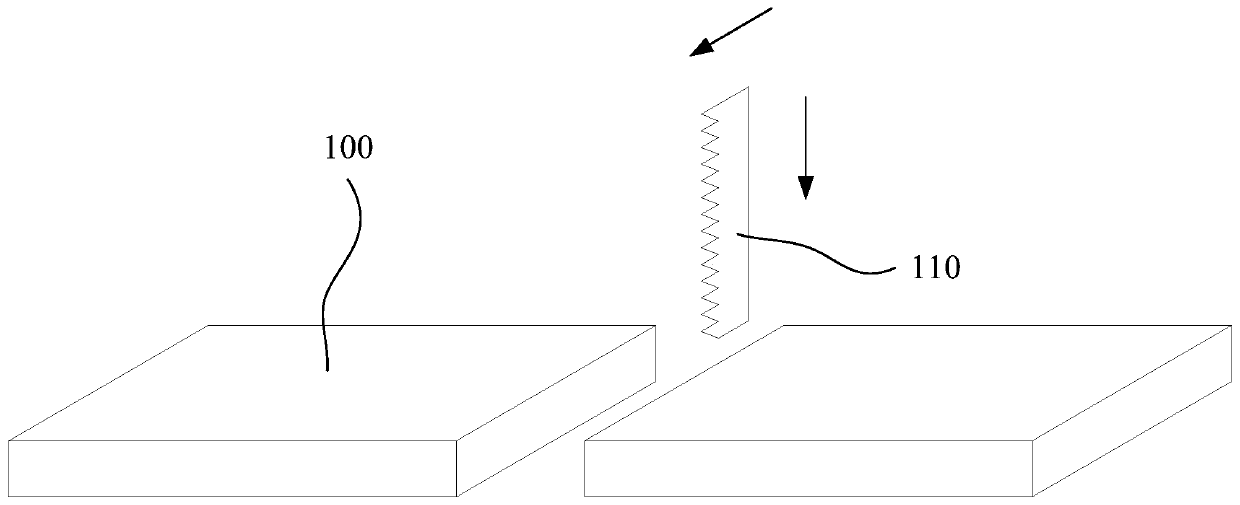

Mold frame standard plate jointed board processing technology

The invention is applicable to the technical field of mold processing, and provides a mold frame standard plate jointed board processing technology. The mold frame standard plate jointed board processing technology comprises the following steps of firstly, carrying out plane rough milling on combined template blanks, and forming a rough machining combined template; then, carrying out plane finishmachining on the rough machining combined template to form a finish machining combined template; then, drilling and processing the finish machining combined template to form a semi-forming combined template; then carrying out sawing processing on the semi-forming combined template, and sawing into a plurality of semi-forming splicing plates which are separated from each other; and finally, carrying out composite processing on the semi-formed splicing plates to form a plurality of mold frame standard plate splicing plates. According to the processing technology, a large number of templates arereduced and the clamping work is reduced, so that the processing efficiency can be greatly improved, and the processing cost is effectively reduced.

Owner:HEYUAN LUNG KEE METAL PRODS

Production process of hexagonal head bolt

Owner:柳州市华侨紧固件有限公司

Hard ice-cream maker

The invention discloses a hard ice-cream maker. The hard ice-cream maker comprises a forming mechanism for forming hard ice creams and a discharging mechanism for receiving the hard ice creams, wherein the forming mechanism comprises a charging mechanism, a pressing-out mechanism, a taking mechanism and a disinfecting mechanism; the discharging mechanism comprises a rotary platform, discharging grooves arranged on the rotary platform and a driving device for controlling rotary motion of the rotary platform; the driving device drives the rotary platform to rotate so as to lead the discharging grooves to correspond to the charging mechanism, the pressing-out mechanism, the taking mechanism and the disinfecting mechanism. The hard ice-cream maker disclosed by the invention has the beneficialeffects that semi-formed hard ice creams can be made into the formed hard ice creams; the miniaturized structure of the hard ice-cream maker can be applicable to small spaces, and convenience is brought for use at places such as small storefronts, stores or selling pavilions.

Owner:BEIJING ZIXUN TECH

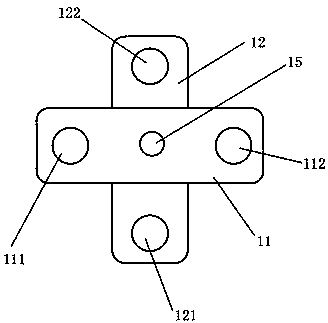

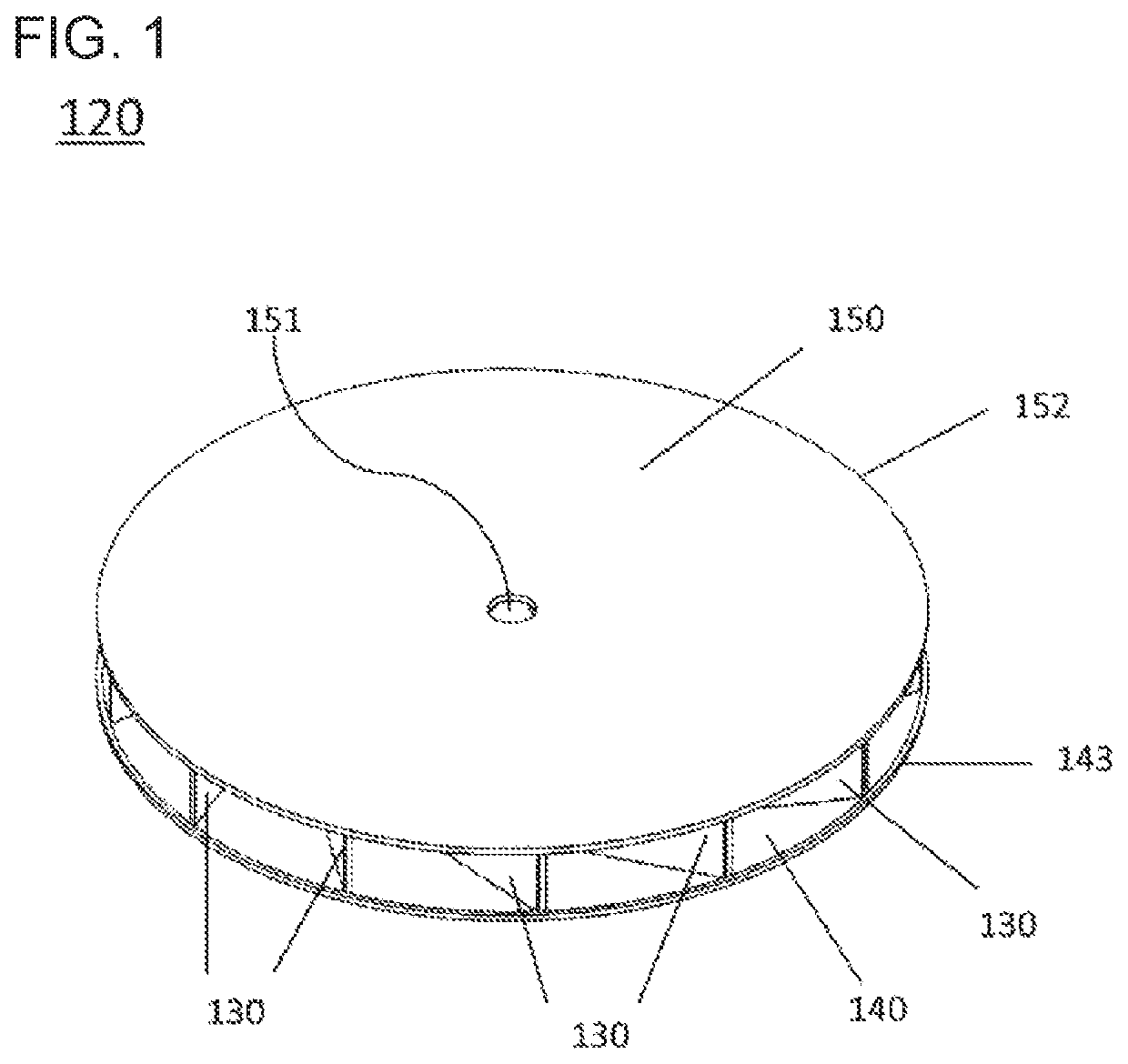

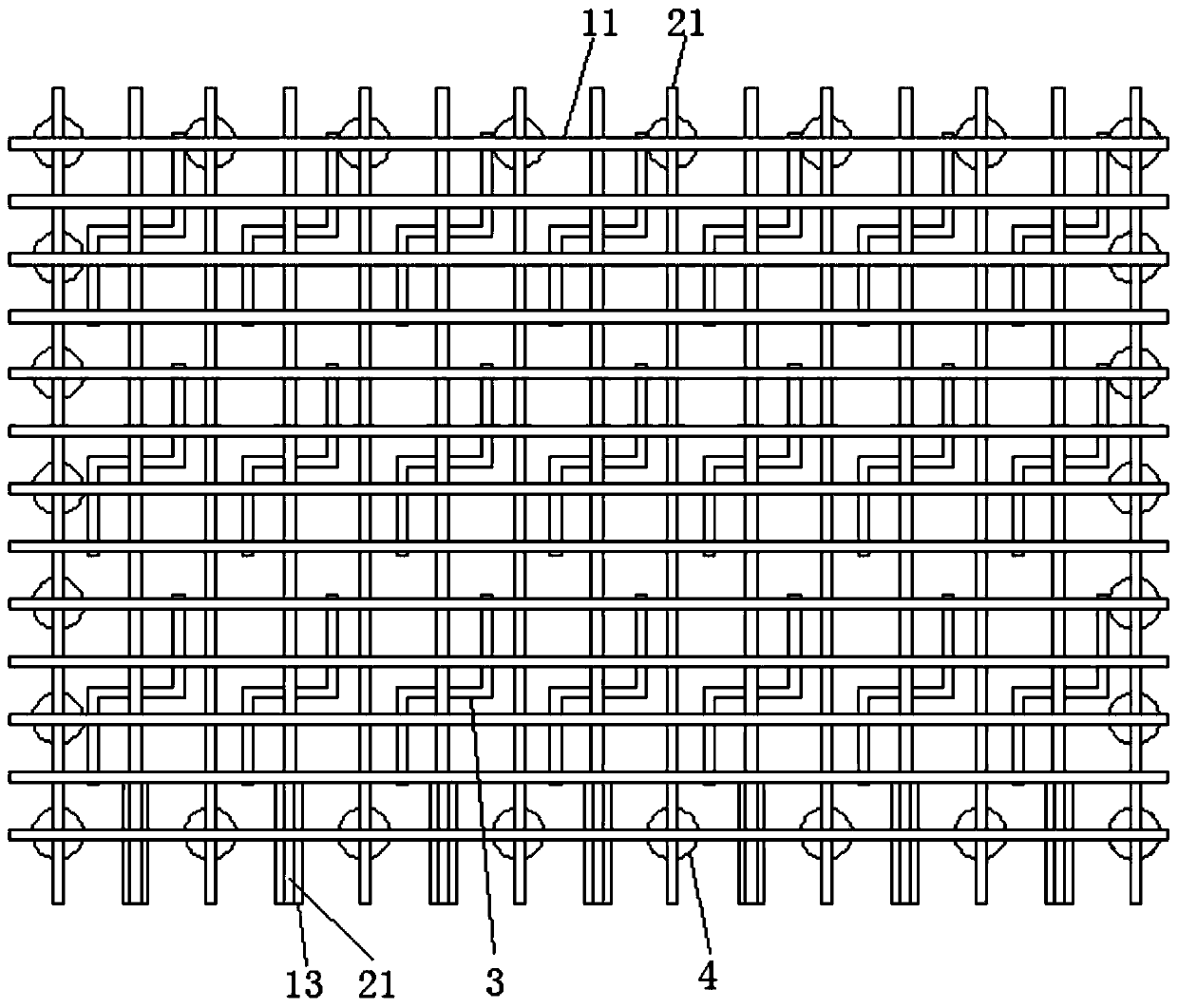

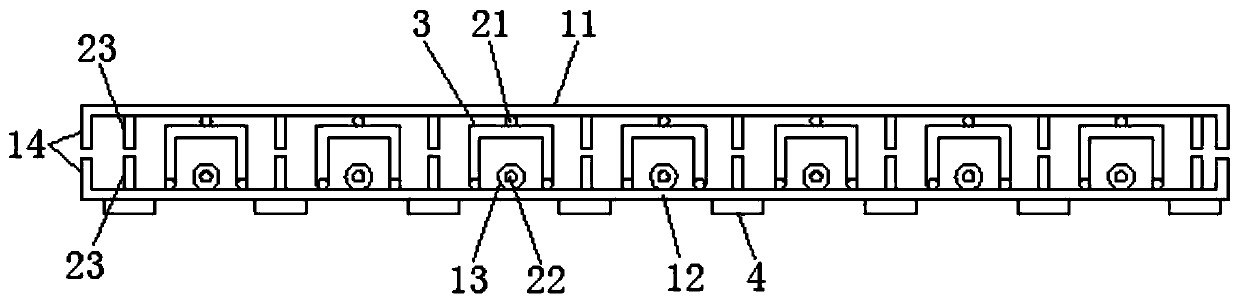

Overall mold entering structure for semi-formed steel bar mesh

PendingCN110094017AImprove connection strengthImprove work efficiencyWire networkCeramic shaping apparatusCross connectionEngineering

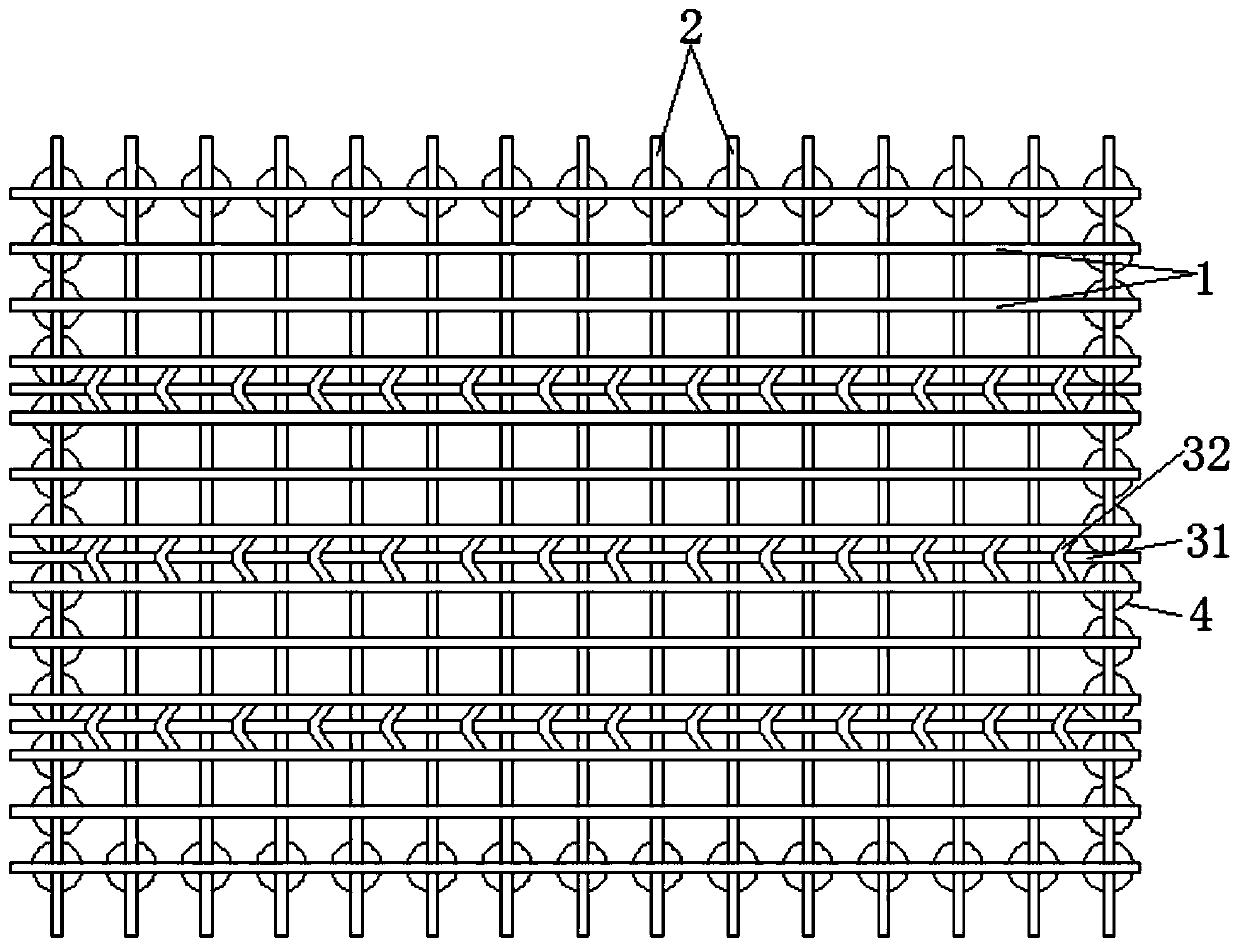

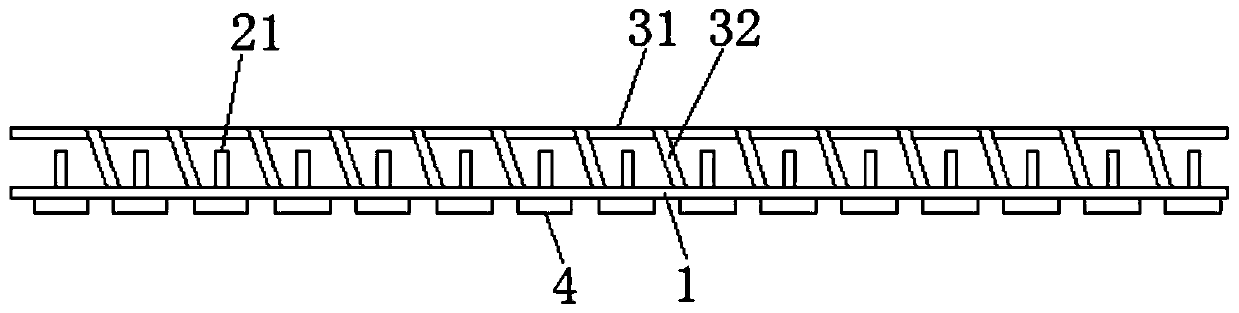

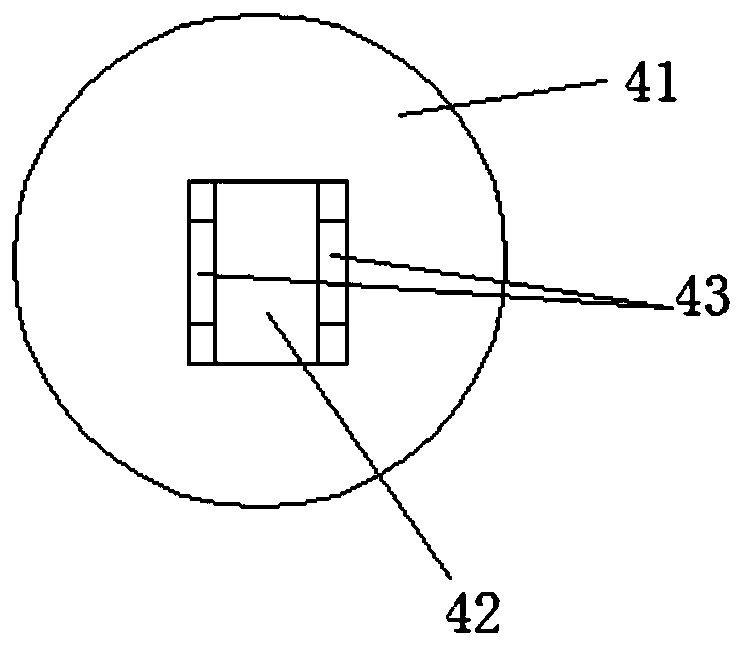

The invention provides an overall mold entering structure for a semi-formed steel bar mesh. The overall mold entering structure comprises a transverse steel bar assembly, a longitudinal steel bar assembly, a middle connecting assembly and a bottom positioning assembly; the transverse steel bar assembly comprises a plurality of transverse steel bars which are arrayed in an evenly distributed mode,and the longitudinal steel bar assembly comprises a plurality of longitudinal steel bars which are arrayed in an evenly distributed mode; the transverse steel bars and the longitudinal steel bars areconnected in a crossed mode and are perpendicular to each other; the middle connecting assembly comprises reinforcing steel bars and a V-shaped connecting frame; the two ends of the bottom of the connecting frame are connected with the adjacent transverse steel bars correspondingly, and the top corner of the connecting frame is connected with the reinforcing steel bars; and the bottom positioningassembly comprises a plurality of positioning discs, and the positioning discs are located at the junctions on the outermost sides of the transverse steel bars and the longitudinal steel bars and located at the bottommost position. By adopting the overall mold entering structure for the semi-formed steel bar mesh, manufacturing does not need to be conducted in a forming mold, production can be conducted at any moment, operation is convenient, the time is saved, and the working efficiency is improved.

Owner:苏州良浦节能新材料股份有限公司

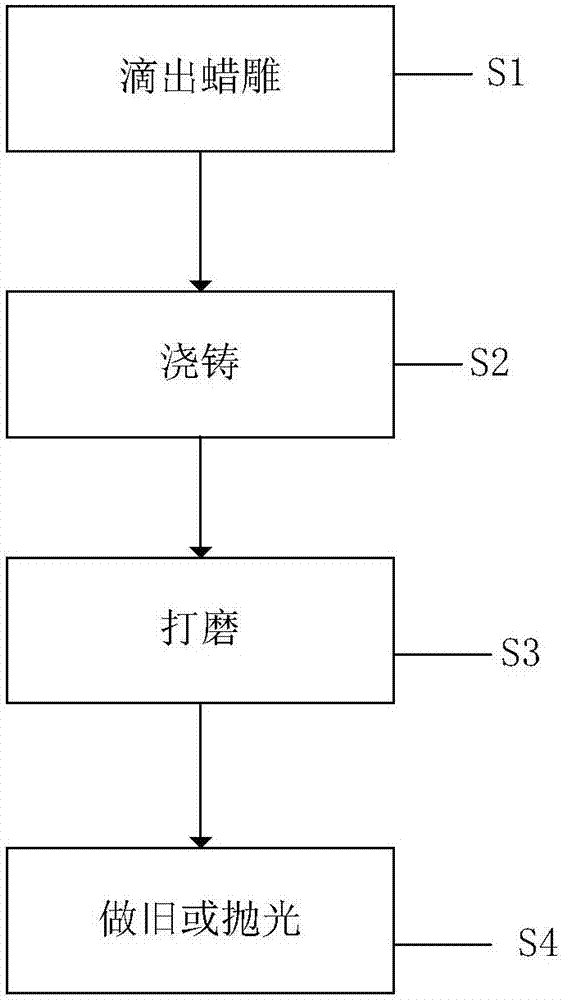

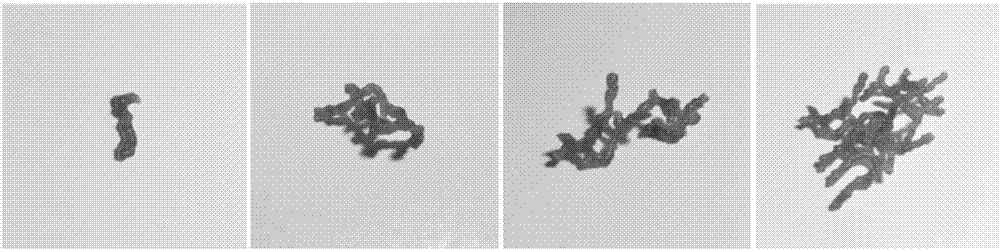

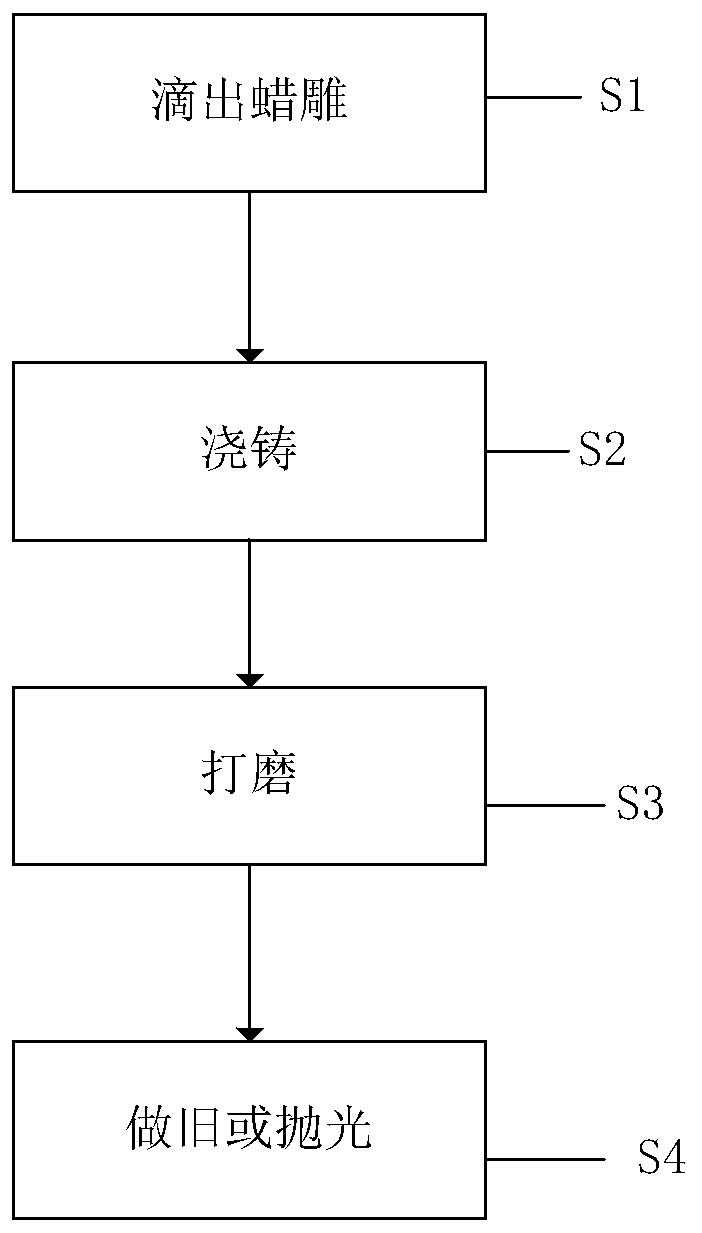

Jewelry manufacturing method based on wax dropping

The invention discloses a jewelry manufacturing method based on wax dropping. The jewelry manufacturing method comprises the following steps that a wax raw material is selected and melted through an electric soldering iron, a wax sculpture is formed in a dropped mode through the wax raw material by the electric soldering iron, and the wax sculpture is matched with jewelry in shape; from different directions, a plurality of water ports are utilized for simultaneous pouring, and then semi-forming type jewelry is obtained; the semi-forming jewelry is ground; according to the colors of the jewelry, making-replica or polishing treatment is conducted, and then the formed jewelry is obtained. According to the jewelry manufacturing method based on wax dropping, the wax dropping technology is adopted for the first time to design the wax sculpture, thus wax sculpture forming is facilitated, the thickness of formed lines can be uniform, and the jewelry manufacturing method is suitable for complex-level jewelry designing; and the quality and grade of a finished product are effectively improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Device and method for forming end of coiled spring

A coil spring end forming apparatus is provided that includes a pair of horizontally disposed parallel rollers 8; a mandrel 22; a stopper 20 that is provided adjacent to the circumferential surface of the mandrel 22 and is moved up or down and rotated integrally with the mandrel 22; a clamp jig 24 that is provided so as to be movable toward or away from the mandrel 22 and that holds a semi-formed spring 30 in cooperation with the mandrel 22, and a pusher 12 for pushing the semi-formed spring 30 toward the stopper 20, wherein in a state in which the axis of the mandrel 22 is positioned between the axes of the parallel rollers 8 and the semi-formed spring 30, a clamp portion 2 holds the semi-formed spring 30 at the inner side of a triangle formed by the axes of the parallel rollers 8 and the semi-formed spring 30 and rotates around the axis along the winding direction of the semi-formed spring 30 to form a pigtail portion at one end of the semi-formed spring 30, and a coil spring end forming method is further provided.

Owner:MITSUBISHI STEEL MFG CO LTD

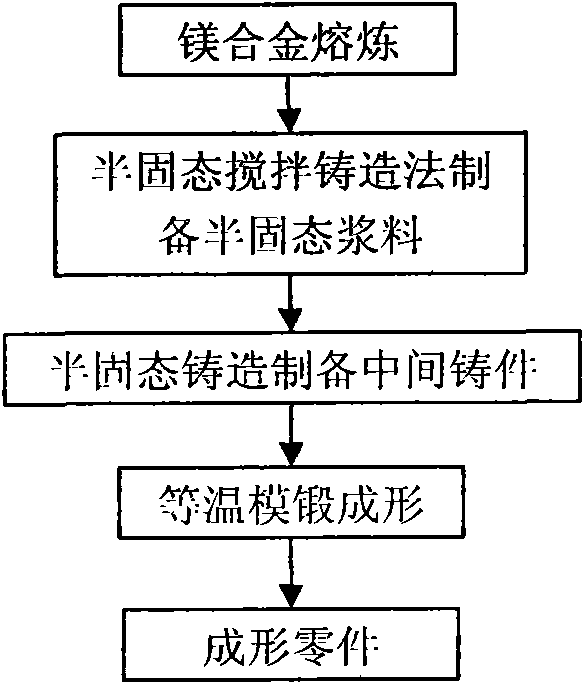

Dual-controlled composite forming method for casting and forging of magnesium alloy

The invention relates to a dual-controlled composite forming method for the casting and forging of magnesium alloy, which is suitable for improving the plastic deformation capacity of the magnesium alloy, and can meet the requirement of producing a high-performance magnesium alloy product of a relatively complex shape. The method comprises the following steps of: preparing magnesium alloy pulp with a non-dendritic microstructure through a semi-solid mixing and casting method; casting the magnesium alloy pulp in a forming mould through a semi-solid rheocasting method, wherein a cast obtained after the cooling and solidification serves as a semi-formed part; heating the cast to 2-10 DEG C above the solidus temperature in a forging and forming mould; and die forging and forming the cast to obtain a magnesium alloy part. The method can be used for producing magnesium alloy parts of complex shapes, and produced parts have the advantages of excellent mechanical properties, high dimensional accuracy and strong deformation capacity.

Owner:CHONGQING UNIV

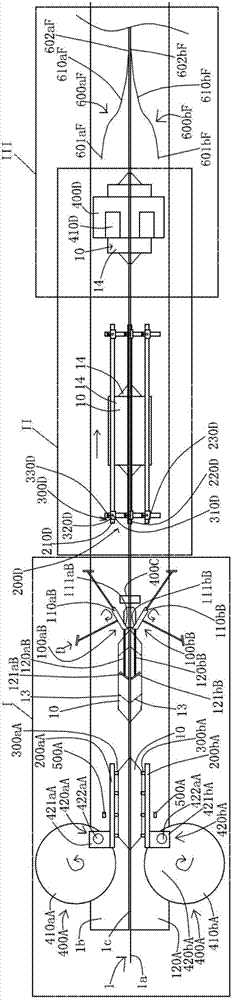

Semi-formed product integral machining device of three-layer composite bag

PendingCN107972320AIncrease productivityBag making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a semi-formed product integral machining device of a three-layer composite bag. The semi-formed product integral machining device sequentially comprises a semi-formed product conveying device, an opening opening device, an opening angle opening device, a forming device, a spread-out shaping device, a gluing bottom pasting device and a bottom pasting bonding device in the semi-formed product advancing direction. By means of the semi-formed product integral machining device, semi-formed products can be subjected to conveying, opening opening, opening angle opening, forming, spread-out shaping, gluing bottom pasting, bottom pasting bonding and other procedures fully automatically, and the production efficiency is greatly improved.

Owner:湖南鸿江包装有限公司

Heat treatment process for precision stainless steel processing

ActiveCN108977641AResilientNeatnessFurnace typesHeat treatment process controlHydraulic cylinderHeating time

The invention discloses a heat treatment process for precision stainless steel processing. The heat treatment process comprises the following process steps of blank preparation, heating treatment, primary shaping, primary cooling, grinding, secondary shaping, final shaping and controlled cooling; a hydraulic cylinder is arranged in a specially-made heating furnace, and during heating, a blank in the heating furnace is extruded by a hydraulic rod, so that the blank has a better plane and shape through extrusion, stainless steel is hammered by the hydraulic cylinder, the blank is continuously tightened, and the semi-formed stainless steel is put into a shaping furnace for heating; and the temperature of a high-temperature segment is 500-700 DEG C, and the heating time 30-40 min. The heat treatment process is novel in structure, the stainless steel is subjected to final shaping after primary shaping and secondary shaping in the heating process, and the blank is extruded through an extrusion plate in the shaping furnace for repeated shaping, so that the blank has certain toughness and plane neatness, the side surface of the stainless steel is super-flat, and the quality of the stainless steel is protected conveniently during heating under the protection of protective gas.

Owner:江苏贯森新材料科技有限公司

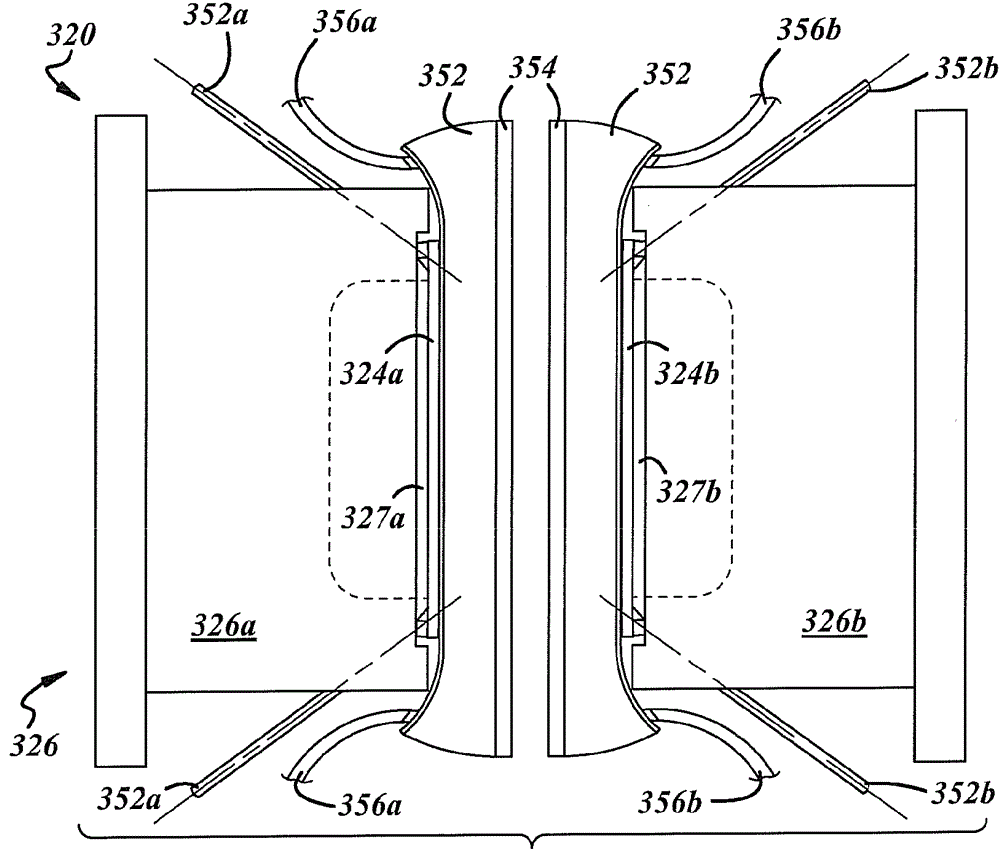

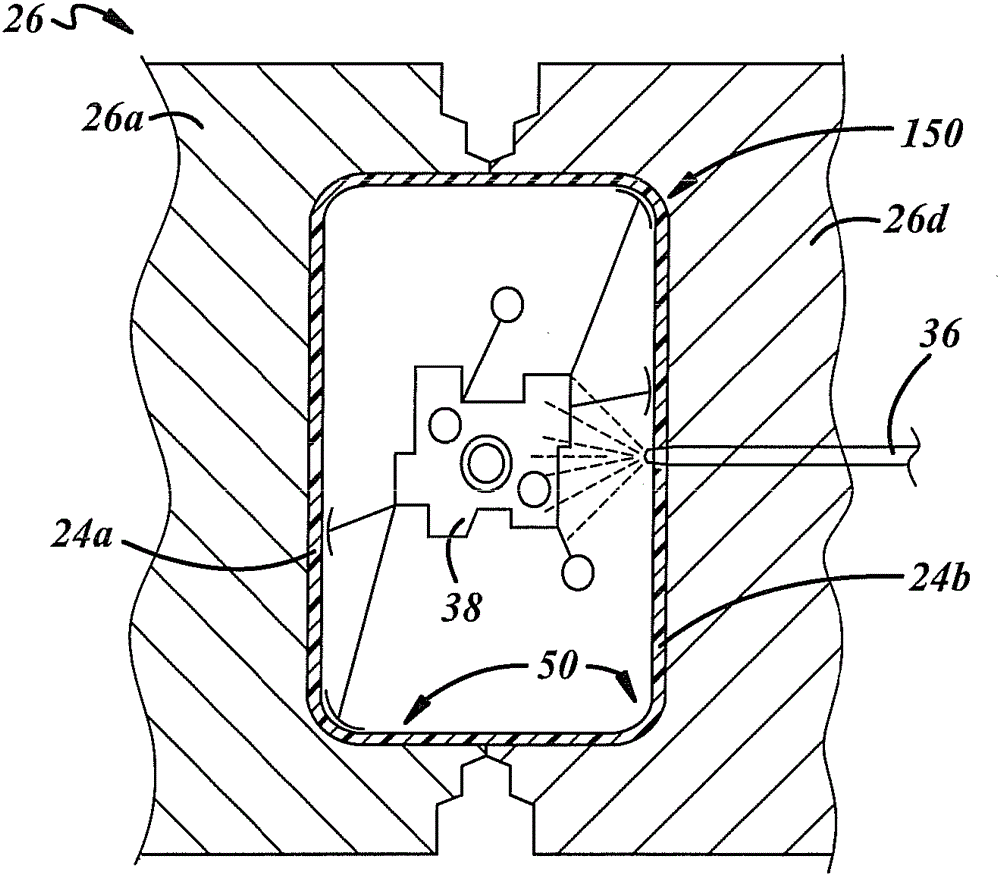

container manufacturing

A method of manufacturing a product comprising extruding a parison; dividing said parison into parison halves by cutting a partially expanded parison or pulling apart a longitudinally weakened parison; and forming the formed parison against respective mold halves. Describe the parison half. The method may further comprise applying a film against the parison half and / or the mold half; and forming the film and parison half against the mold half to produce a multilayer product half. An apparatus for performing the method is also disclosed.

Owner:TI AUTOMOTIVE TECH CENT

Additive manufacturing and subtractive manufacturing combined machining equipment

ActiveCN107774992AImprove applicabilityImprove processing efficiencyAdditive manufacturing apparatusMachiningAdditive layer manufacturing

Additive manufacturing and subtractive manufacturing combined machining equipment comprises an additive manufacturing device, a cleaning device, a subtractive manufacturing device and a transferring device, wherein the additive manufacturing device comprises an energy source mechanism and a forming mechanism; the forming mechanism comprises a forming cavity and a forming substrate arranged in theforming cavity; the energy source mechanism is used for forming powder on the forming substrate, so that a semi-formed workpiece can be obtained, the semi-formed workpiece on the forming substrate issubjected to repeated forming, and a formed workpiece is obtained; the transferring device is used for transferring the forming mechanism and the workpiece on the forming substrate, and transferring is performed between any two of an additive manufacturing work position, a cleaning work position and a subtractive manufacturing work position; the cleaning device is used for cleaning the workpiece on the forming substrate; the subtractive manufacturing device is used for machining the workpiece on the forming substrate. According to the equipment, subtractive manufacturing can be combined between the semi-formed workpiece and the formed workpiece of additive manufacturing, inner and outer surfaces of the semi-formed workpiece can be subjected to subtractive manufacturing timely and accurately, and the applicability and the machining efficiency of the formed workpiece are improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Manufacturing method and manufacturing device for resin fan

Owner:MATSUDAKANAGATAKOGYO CO LTD

Full-automatic progressive die for hinge shaft

The invention relates to the technical field of machining, and discloses a full-automatic progressive die for a hinge shaft. The progressive die comprises an upper die holder and a lower die holder; aguide hole punching die block, a cutting die block, a semi-forming die block, a full forming die block, a side hole punching die block and a cutting-off die block are sequentially arranged on the upper die holder. The machining procedure of a right front car door lower hinge is subjected to new arrangement, on the basis of ensuring machining precision, the right front car door lower hinge can bemachined in the same machining die, through one machining die, personal losses can be reduced, and machining speed is improved; and the progressive die can effectively solve the problems that the right front car door lower hinge is high in forming cost and complex in process

Owner:HUBEI HONGSHENGCHANG ELECTRONICS CO LTD

Magnesium alloy construction member step temperature forming method

InactiveCN102172750BAchieve harmonizationImprove performanceMetal-working apparatusThermal energyHeating furnace

Owner:ZHONGBEI UNIV

Rapid cooling plastic material extrusion mold of backflow ejector pin wiping glue layer

The invention discloses a rapid cooling plastic material extrusion mold of a backflow ejector pin wiping glue layer. The mold structurally comprises a control machine, a forming chamber, and a bottombox; the control machine is arranged on the forming chamber and is electrically connected with the forming chamber, the forming chamber is locked with the bottom box, the forming chamber is composed of a forming frame, a forming inner frame, a backflow chamber and an ejector pin structure. The forming frame is locked with the forming inner frame, the forming inner frame is engaged with the backflow pipe, the ejector pin structure is arranged on the forming frame and the forming inner frame, during machining, a semi-formed mold enters from the left end of the forming chamber, the formed mold isout of the right end, an upper ejector pin and a lower ejector pin achieve wiping of glue scales on the left side face of the forming frame, the glue scales on the lower surface of a left mold frameis wiped by a right bottom mold frame, in the wiping process, an air ring machine blows off part of glue scale, the cleaning effect of the wiping glue layer is improved in an assisting manner, meanwhile, the wiping layer forms the cluster shape, the friction force is increased, and the thick scale layer is cleared.

Owner:苏州科知律信息科技有限公司

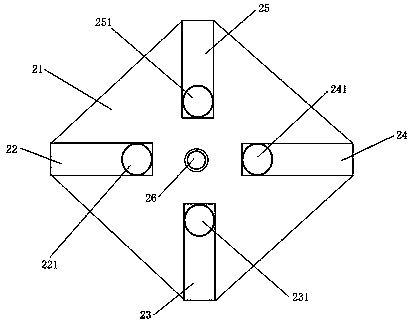

Semi-formed reinforcement cage overall die inlet structure

PendingCN110091432AImprove stabilityEasy to operateCeramic shaping apparatusBuilding reinforcementsCross connectionEngineering

The invention provides a semi-formed reinforcement cage overall die inlet structure which comprises an outer side steel bar assembly, an inner side steel bar assembly, a supporting assembly and a positioning assembly. The inner side steel bar assembly is located on the inner side of the outer side steel bar assembly. The inner side steel bar assembly comprises first top steel bars and first bottomsteel bars. The outer side steel bar assembly comprises second top steel bars and second bottom steel bars. The first top steel bars and the second top steel bars are connected in a crossed manner toform an upper steel bar net, and the first bottom steel bars and the second bottom steel bars are connected in a crossed manner to form a lower steel bar net. The supporting assembly comprises multiple supporting frames. The positioning assembly comprises multiple positioning discs which are located at the connecting positions of the outermost sides of the first bottom steel bars and the second bottom steel bars, and the positioning discs are located below the first bottom steel bars. By the adoption of the semi-formed reinforcement cage overall die inlet structure, manufacturing does not need to be conducted in a forming die, production can be conducted at any time, operation is convenient, time is saved, and the work efficiency is improved.

Owner:苏州良浦节能新材料股份有限公司

Preparation method of metal foil glass mosaic

InactiveCN110406303AAccelerated corrosionGood weather resistanceOrnamental structuresFull life cycleMetal foil

The invention discloses a preparation method of metal foil glass mosaic. After a metal foil is pasted to a sodium calcium glass substrate, the sodium calcium glass substrate is placed in an environment at 580 DEG C to 875 DEG C; when the sodium calcium glass substrate is semi-formed, a glass stock solution in a fusion state is taken out with a liquid take-up rod from a smelting furnace, the two materials are placed in a 60-ton hydraulic press at the same time for high-pressure pressurizing forming, and the formed glass mosaic is obtained. At the high temperature environment, the metal foil isfused into a glass body in a manner of keeping an original color, the metal foil can theoretically be permanently free of discoloring and character varying under the anaerobic condition, the long product life can be ensured after the product is used by a user once, and great advantages are provided for environment protection; the using cost of precious metal is greatly reduced, the product full life cycle is prolonged, and the corrosion resistance and good weather resistance of the glass are increased while the texture and color of the metal foil are maintained; and in cooperation with the refraction and reflection performance of the glass, the product can better show the characters of the metal foil and the glass, and is an environment-friendly and innovative product.

Owner:倪寅 +1

A kind of jewelry making method based on dripping wax

InactiveCN107377887BModerate fluidityQuality improvementFoundry mouldsFoundry coresMetallurgyEngineering

The invention discloses a jewelry manufacturing method based on wax dropping. The jewelry manufacturing method comprises the following steps that a wax raw material is selected and melted through an electric soldering iron, a wax sculpture is formed in a dropped mode through the wax raw material by the electric soldering iron, and the wax sculpture is matched with jewelry in shape; from different directions, a plurality of water ports are utilized for simultaneous pouring, and then semi-forming type jewelry is obtained; the semi-forming jewelry is ground; according to the colors of the jewelry, making-replica or polishing treatment is conducted, and then the formed jewelry is obtained. According to the jewelry manufacturing method based on wax dropping, the wax dropping technology is adopted for the first time to design the wax sculpture, thus wax sculpture forming is facilitated, the thickness of formed lines can be uniform, and the jewelry manufacturing method is suitable for complex-level jewelry designing; and the quality and grade of a finished product are effectively improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Semicanal formation rolling machine

ActiveCN101386023BReduce stiffnessImprove flexibilityMetal rolling stand detailsRollsSteel beltHelix

A rolling mill for forming a semi-tube belongs to the technical field of rolling, and is used for solving the problem of one-time forming of steel strips. The technical proposal is that the rolling mill comprises a frame, a rolling part, a transmission part and a cogging adjusting mechanism. The rolling part consists of a guide roller, a pre-forming roller, a semi-forming roller, a forming rollerand a rolling roller which are arranged in sequence. The upper roller and the lower roller of the guide roller are cylindrical rollers, while the other four rollers respectively consist of upper rollers and lower rollers which are provided with mutually matched arc roll surfaces. The rolling mill can roll the steel strip with the thickness of 2-3mm into semi-tubes in different diameters. The thickness of the wall of the semi-tube rolled by the rolling mill is evenly changed with the curvature thereof, and the semi-tube shows no folding. The finished product semi-tube has the advantages of lowrigidity and good flexibility, and can be smoothly and spirally wound or directly laid on a cylindrical shell of a device while arranging the device.

Owner:HEBEI INSTALLATION ENG

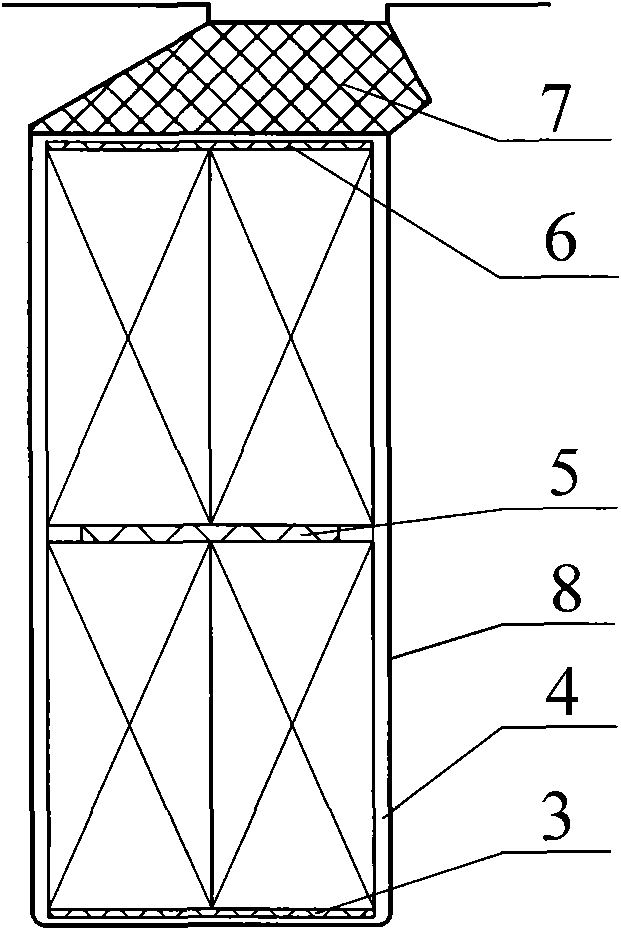

Scraper-type semi-forming casting mould

The invention discloses a scraper-type semi-forming casting mould. The scraper-type semi-forming casting mould comprises a casting mould (1), a back pushing plate (2), a back sand plate (3), a semi-forming sand shell (4), a casting (5), a scraper (6), a front sand plate (7) and a front iron plate (8), wherein the back pushing plate (2), the back sand plate (3), the front sand plate (7) and the front iron plate (8) are installed in the inner cavity of the casting mould (1); a motor is started to enable the casting mould (1) to rotate after moulding sand is filled in the inner cavity of the casting mould (1); and the scraper extends into the inner cavity of the casting mould (1) to scrape the moulding sand to be molded and then withdraws the scraper (6), and then molten iron is cast. The scraper-type semi-forming casting mould is simple in structure, convenient to operate and capable of increasing the efficiency and saving the cost.

Owner:邹佳俊

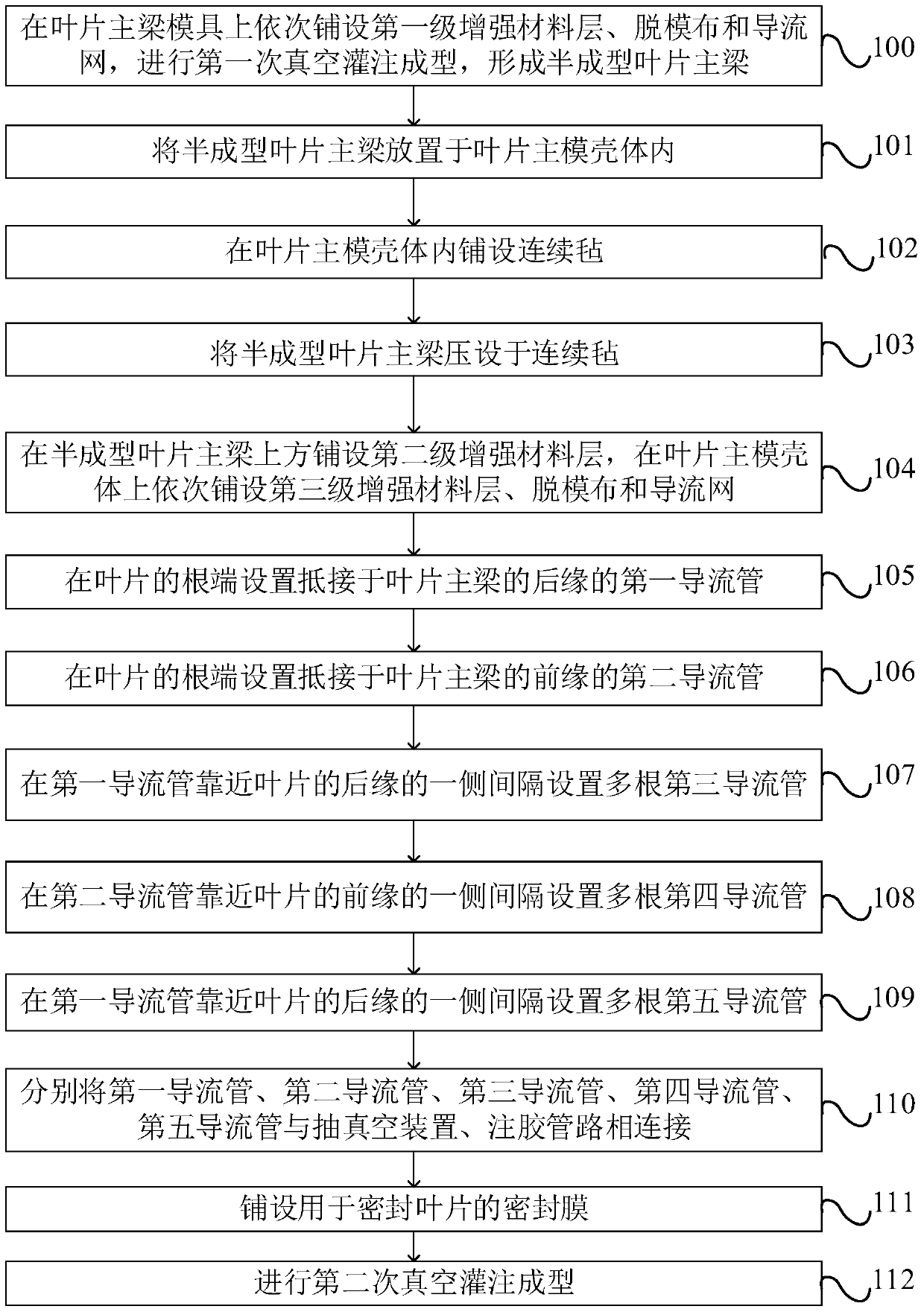

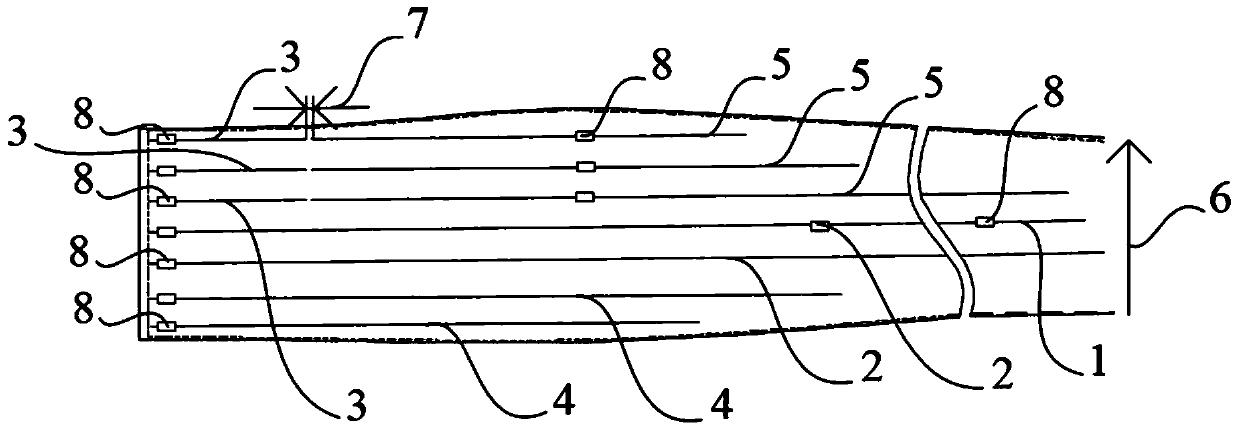

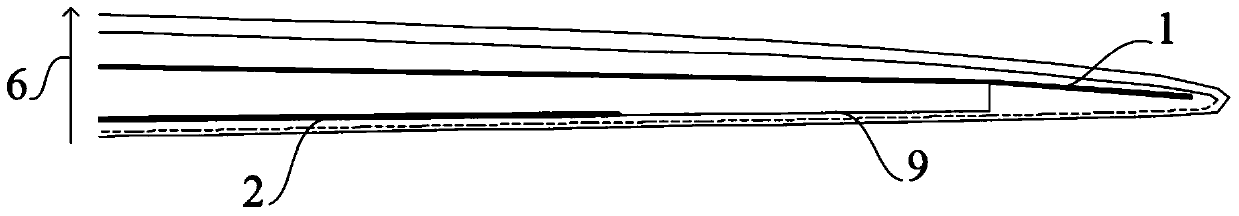

Forming method of blade main beam

ActiveCN107225778BImprove molding qualityQuality improvementDomestic articlesMechanical engineeringSemi-formed

The invention discloses a forming method for a blade main beam. The forming method comprises the following steps of: sequentially paving a primary reinforcing material layer, de-molding cloth and a diversion net on a blade main beam mould to perform primary vacuum filling forming, thereby forming a semi-formed blade main beam; putting the semi-formed blade main beam into a blade main mould shell; and paving a secondary reinforcing material layer above the semi-formed blade main beam, and sequentially paving a tertiary reinforcing material layer, de-molding cloth and a diversion net on the blade main mould shell to perform secondary vacuum filling forming. According to the forming method disclosed by the invention, the blade main beam with large megawatt stage and a relatively great reinforcing material layer is formed in twice, so that the local cloth layer wrapping problem of the blade main beam is solved, and forming quality of the blade main beam is improved, and therefore, quality of the blade is improved.

Owner:SHANGHAI AEOLON WIND ENERGY TECH DEVGRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com