Vertical far infrared radiation impregnation drying production line

A far-infrared radiation, production line technology, used in progressive dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of left, middle and right impregnation deviation, material warpage, surface blistering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

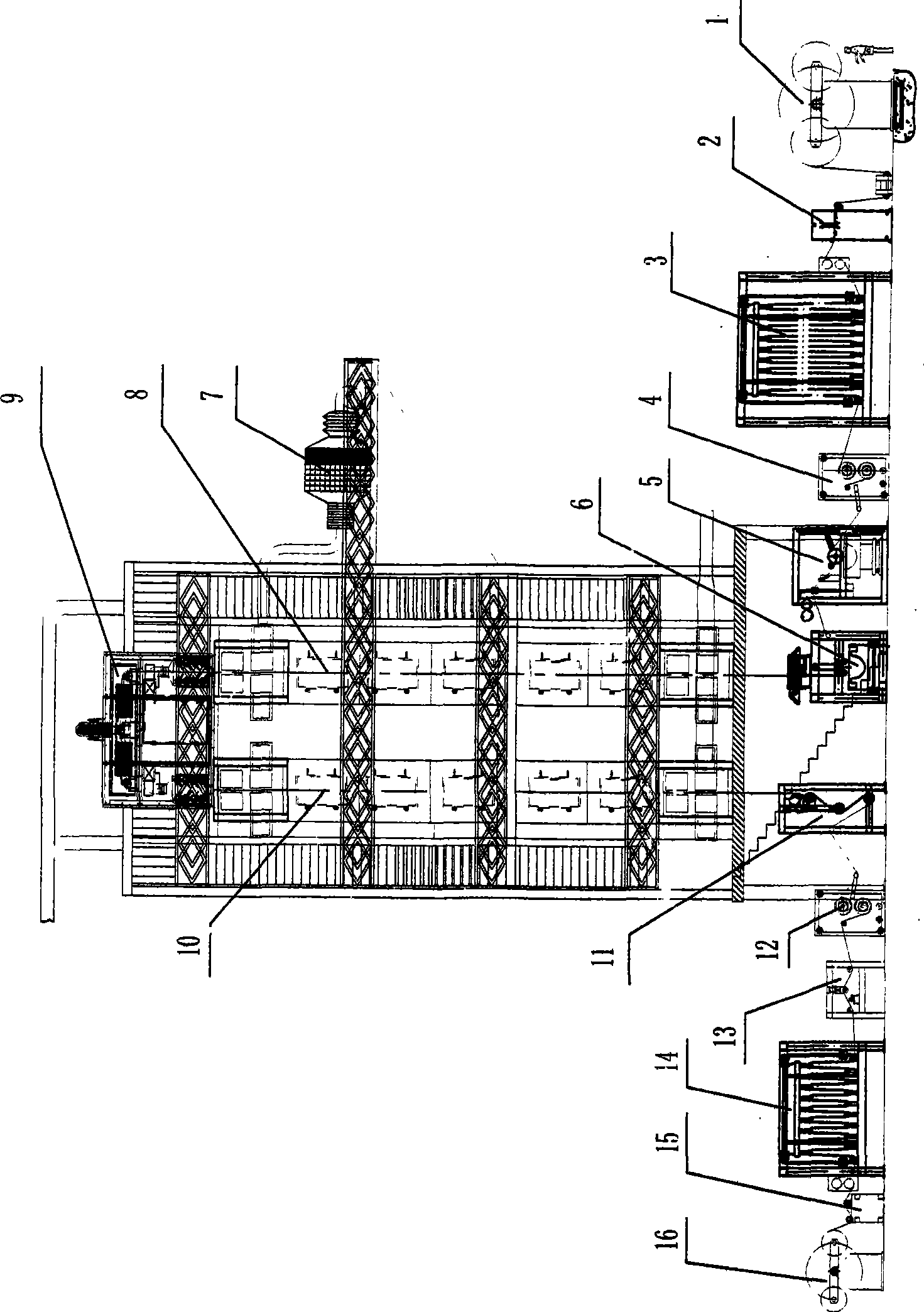

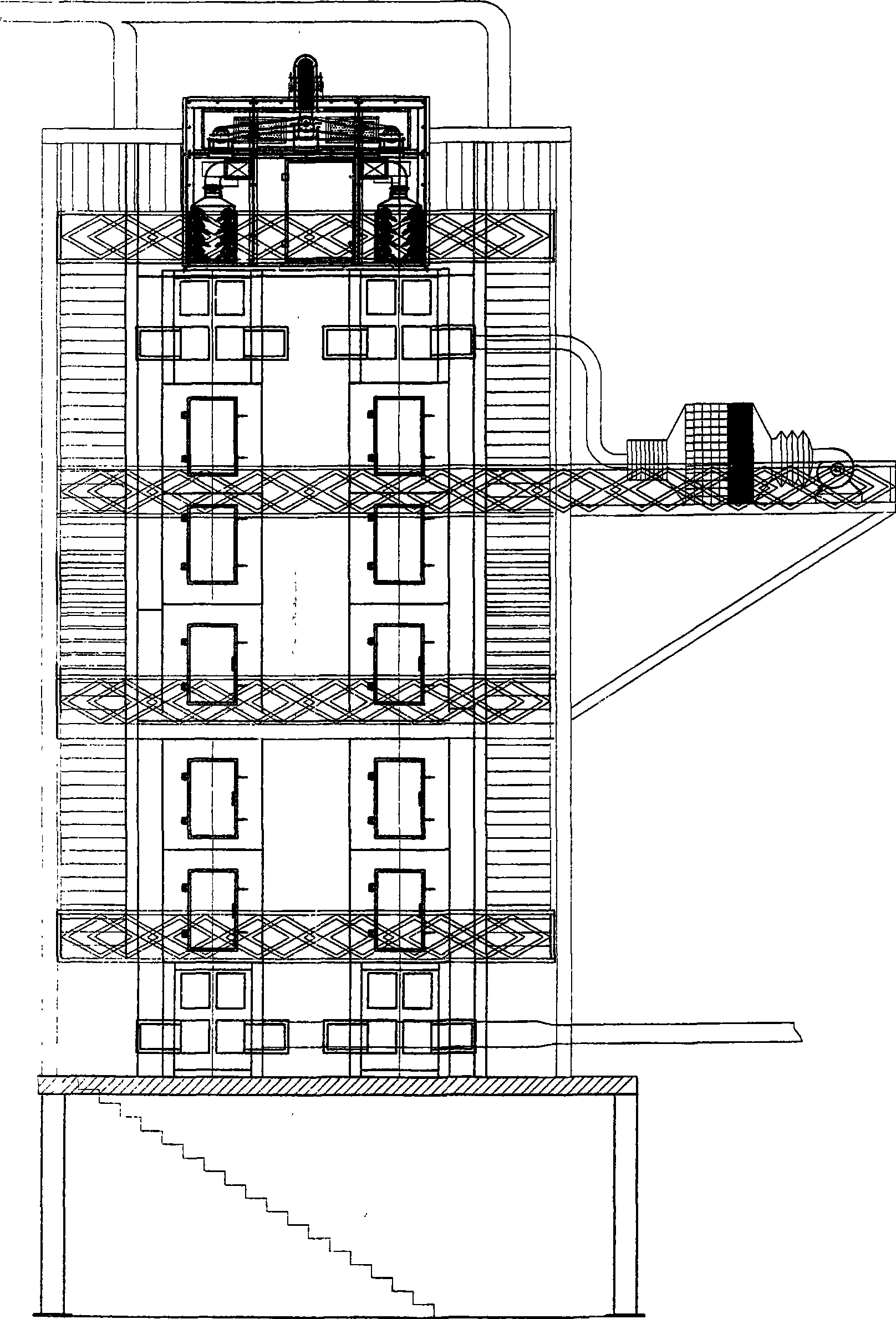

[0006] Vertical far-infrared radiation impregnation and drying production line, which consists of: unwinding machine and tension control 1, cloth splicing machine 2, front storage machine 3, front traction and tension control 4, back coating machine 5, dipping machine 6, hot air exchange Heater 7, ascending oven 8, cold air room 9, descending oven 10, rectifying machine 11, traction machine 12, trimming machine 13, rear stocker 14, tension control 15, winder 16 and form. It is characterized in that: the layout of the vertical far-infrared radiation impregnation and drying production line is vertical (vertical), and the radiant panels are divided into two types: electric heating radiant panel (A) and inner heat conduction oil radiant panel (B). In the vertical direction of the down section of the radiant plate, the left, middle and right temperature controls are separately set up. The left, middle and right respectively pass through the PID self-tuning electric control valve, ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com