High ductility steel for semifocal chord pipe for spud leg and manufacturing method of high ductility steel

A technology of high-toughness steel and pile legs, which is applied in the fields of marine engineering steel and its manufacture, pile leg half-chord pipe steel and its manufacture, and can solve problems such as easy coarse grains, increased manufacturing costs, and production failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

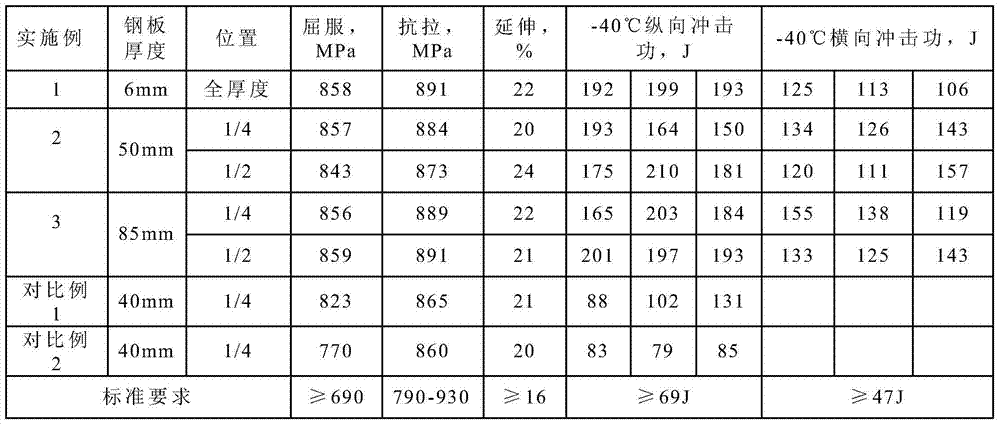

Examples

Embodiment 1

[0065] A kind of high-toughness steel for leg half-chord pipe, the chemical composition content is as follows by weight percentage:

[0066] Carbon 0.05%, silicon 0.04%, manganese 1.18%, phosphorus 0.010%, sulfur 0.003%, chromium 0.74%, nickel 0.70%, molybdenum 0.32%, titanium 0.019%, boron 0.0011%, the rest is iron and unavoidable impurities.

[0067] The manufacturing method comprises the following steps:

[0068] (a) KR molten iron pretreatment: molten iron P=0.075%, after adopting KR molten iron pretreatment sulfur content 0.003%;

[0069] (b) Converter blowing: 210 tons of converter smelting end point composition carbon controlled at [C]=0.036%, S=0.007%, P=0.008%, end point temperature 1645°C;

[0070] (c) Deoxidation alloying: 760 kg of total titanium (3.62 kg titanium / ton steel) is added during the deoxidation alloying process, and the control end point [O]≤550ppm;

[0071] (d) RH refining: the vacuum degree of RH refining is 87Pa, the processing time is 15min, the p...

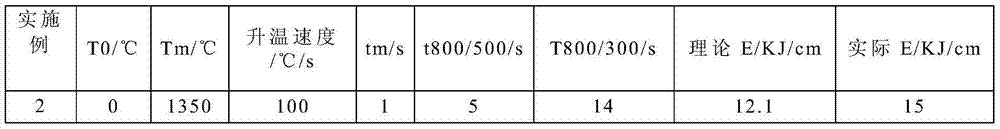

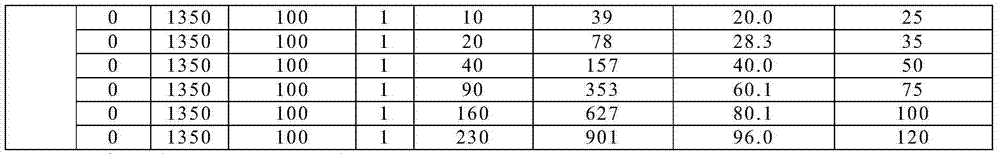

Embodiment 2

[0077] A kind of high-toughness steel for leg half-chord pipe, the chemical composition content is as follows by weight percentage:

[0078] Carbon 0.07%, silicon 0.03%, manganese 1.04%, phosphorus 0.011%, sulfur 0.001%, chromium 0.88%, nickel 0.76%, molybdenum 0.38%, titanium 0.027%, boron 0.0016%, the rest is iron and unavoidable impurities.

[0079] The manufacturing method comprises the following steps:

[0080] (a) KR molten iron pretreatment: molten iron P=0.083%, the sulfur content after using KR molten iron pretreatment is 0.002%.

[0081] (b) Converter blowing: 210 tons of converter smelting end point composition carbon is controlled at [C]=0.032%, S=0.005%, P=0.007%, end point temperature 1642°C;

[0082] (c) Deoxidation alloying: 650 kg of total titanium (3.09 kg titanium / ton steel) is added during the deoxidation alloying process, and the control end point [O]≤550ppm;

[0083] (d) RH refining: the vacuum degree of RH refining is 80 Pa, the processing time is 18 m...

Embodiment 3

[0089] A kind of high-toughness steel for leg half-chord pipe, the chemical composition content is as follows by weight percentage:

[0090] Carbon 0.08%, silicon 0.06%, manganese 1.12%, phosphorus 0.009%, sulfur 0.003%, chromium 0.97%, nickel 0.92%, molybdenum 0.46%, titanium 0.025%, boron 0.0018%, the rest is iron and unavoidable impurities.

[0091] The manufacturing method comprises the following steps:

[0092] (a) KR molten iron pretreatment: molten iron P=0.068%, after adopting KR molten iron pretreatment, sulfur content is equal to 0.002%;

[0093] (b) Converter blowing: 210 tons of converter smelting end point carbon is controlled at [C]=0.038%, S=0.004%, P=0.007%, end point temperature is 1657°C;

[0094] (c) Deoxidation alloying: 700 kg of total titanium (3.33 kg titanium / ton of steel) is added during the deoxidation alloying process, and the control end point [O]≤550ppm;

[0095] (d) RH refining: the vacuum degree of RH refining is 91Pa, the processing time is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com