Production process of hexagonal head bolt

A production process, hexagonal head technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of waste trimming, low head height detection efficiency, and low detection efficiency, so as to avoid head detection, Improve work efficiency and the effect of waste and inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

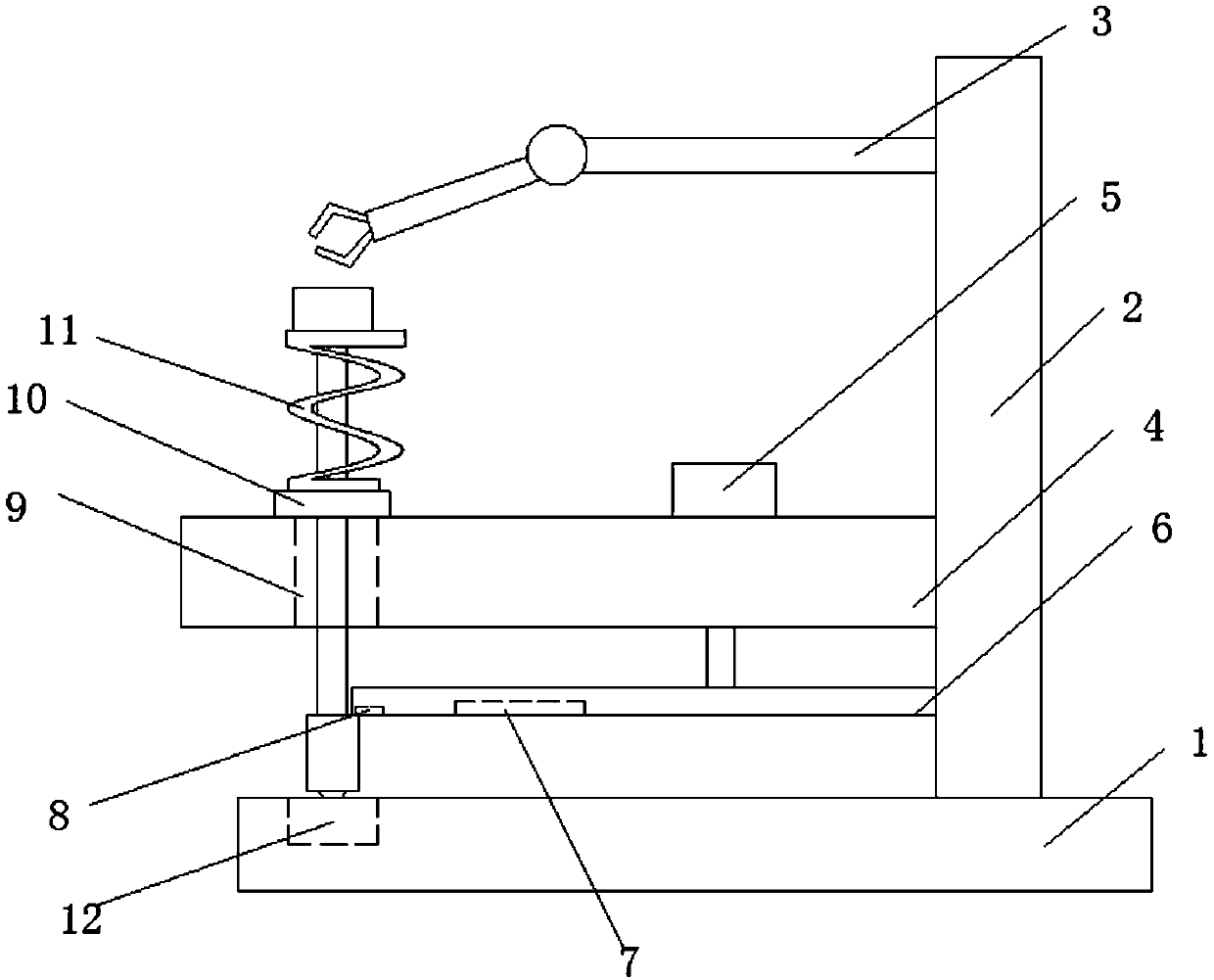

[0025] refer to figure 1 , a production process of a hexagon head bolt in the present embodiment, comprising the following steps:

[0026] S1: According to the required size, cut the cylindrical blank of appropriate size;

[0027] S2: The cylindrical ingredients described in S1 are placed on the first station of the multi-station cold pier machine, and the first station of the multi-station cold pier machine cold-heads the upper end of the cylindrical ingredients into a preforming head The outer edge of the outer lower end of the preformed head is smooth and excessive, and at the same time, the first station of the multi-station cold pier machine cold-heads the lower end of the cylindrical ingredient into a screw part;

[0028] S3: The cylindrical ingredients described in S2 are moved to the second station of the multi-station cold pier machine, and the second station of the multi-station cold pier machine cold-heads the preformed head into a semi-formed head, The outer edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com