Semi-forming centrifugal casting mould

A technology of centrifugal casting and casting molds, which is applied in the field of pouring machines, can solve the problems of large tool consumption, large machining allowance, labor and time-consuming, etc., and achieve the effects of saving materials, increasing yield, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

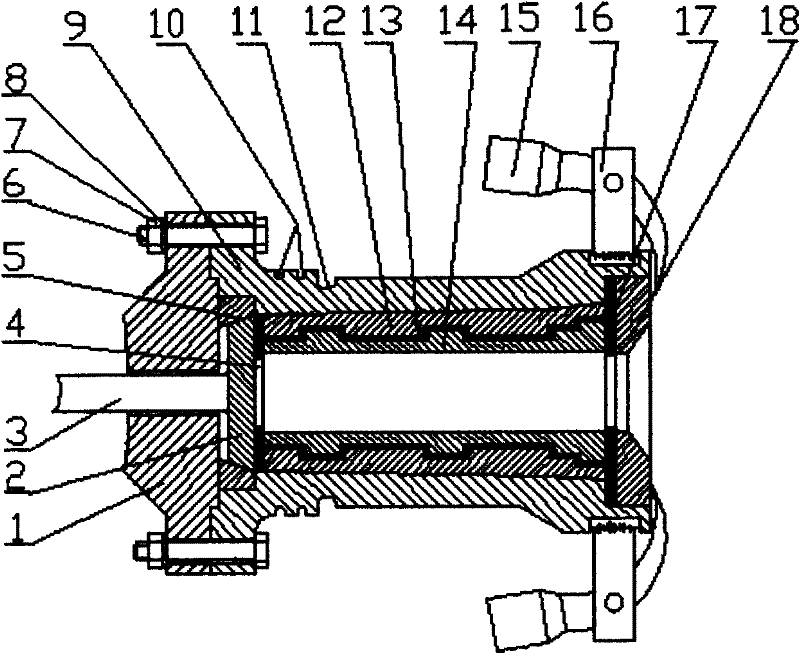

[0014] Such as figure 1 As shown, the casting mold includes a main shaft flange 1, a ejector plate 2, a ejector 3, a positioning plate 5, a bolt 6, a nut 7, a casting mold 9, a water tank 10, a water blocking tank 11, a flap forming sleeve 12, a fly Hammer 15 and stuffy cover 18, raise the positioning plate 5 at one end of the inner cavity of the casting mold 9 to install the ejector plate 5 with the ejector rod 3, the main shaft flange 1 is installed on the casting mold 9 through bolts 6 and nuts 7, and the casting mold 9 inner chambers are installed with flap-opening forming sleeves 12, and at the other end of the casting mold 9 inner chambers, a stuffy cover 18 is installed through a flyweight 15.

[0015] In the semi-formed centrifugal casting mold of the present invention, a water groove 10 and a water blocking groove 11 are arranged on the outer wall of the casting mold 9 .

[0016] In the semi-formed centrifugal casting mold of the present invention, the rear asbestos ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com