Semi-formed reinforcement cage overall die inlet structure

A technology of steel cages and steel bars, applied in structural elements, ceramic molding machines, building components, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

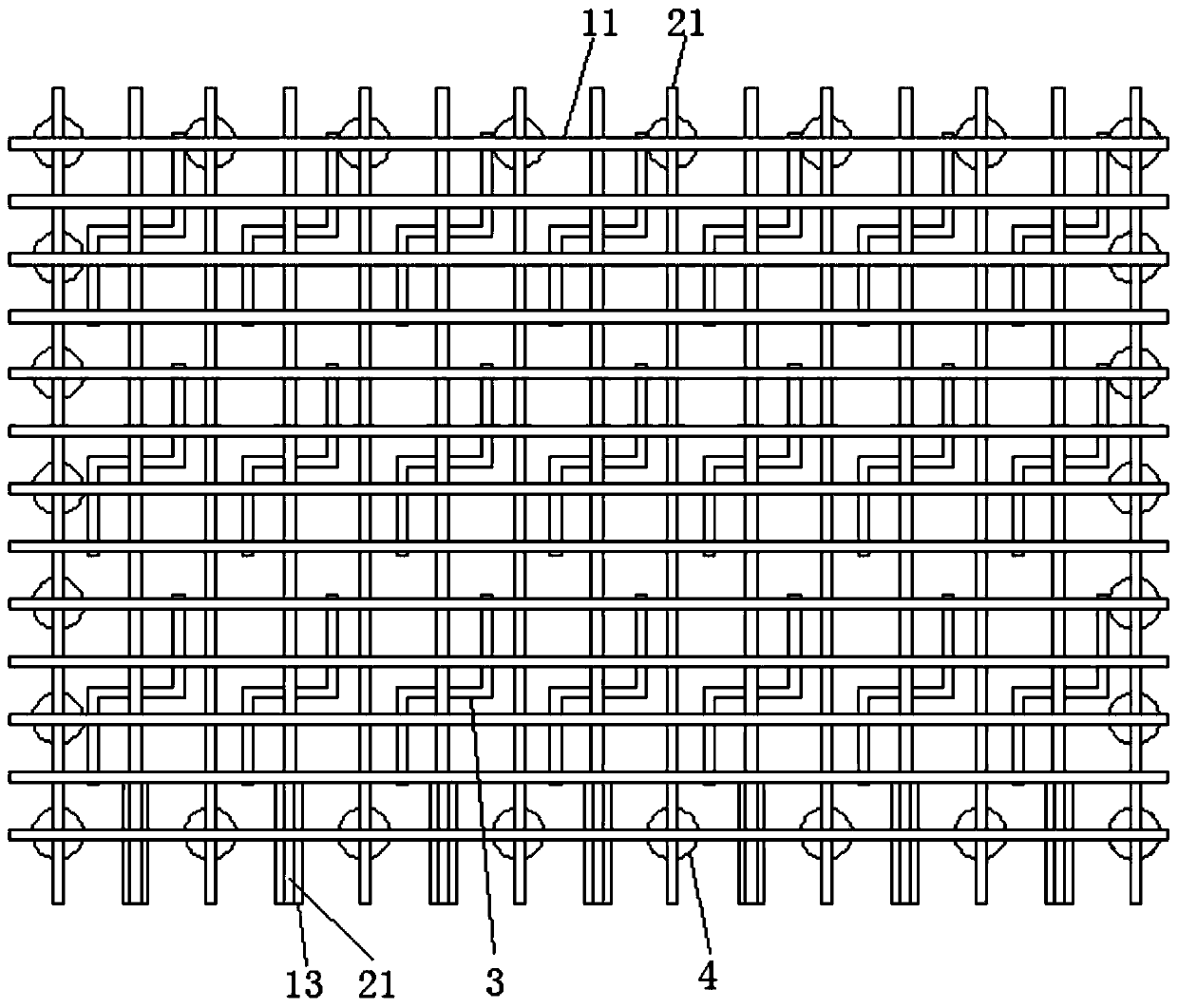

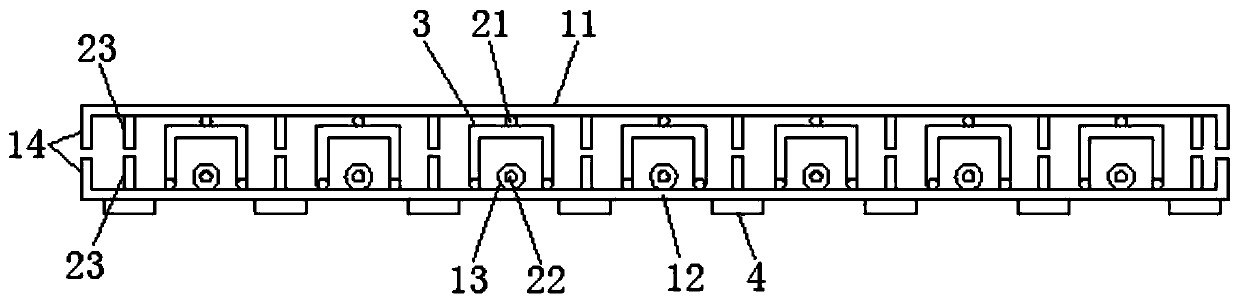

[0023] see Figure 1-2 , the figure shows a semi-formed reinforcement cage integral molding structure provided by Embodiment 1 of the present invention, which includes an outer reinforcement assembly, an inner reinforcement assembly, a support assembly and a positioning assembly, and the inner reinforcement assembly includes a first top set up and down The steel bar 11 and the first bottom steel bar 12, the first top steel bar 11 and the first bottom steel bar 12 are evenly arranged; the outer steel bar assembly includes the second top steel bar 21 and the second bottom steel bar 22 arranged up and down, and the first top steel bar 11 is located at The outside of the second top reinforcement bar 21, the first bottom reinforcement bar 12 is positioned at the outside of the second bottom reinforcement bar 22; The steel bars 22 are cross-connected to form the lower steel mesh; the support assembly includes a number of support frames 3 arranged between the upper steel mesh and the...

Embodiment 2

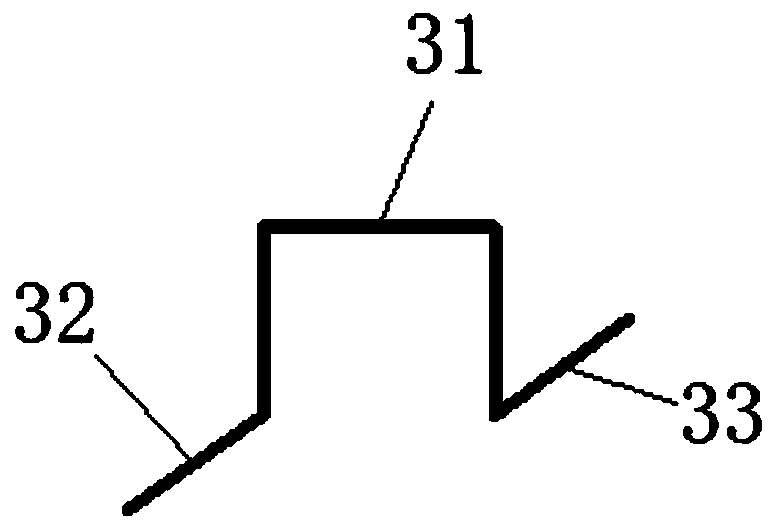

[0027] see image 3, the figure shows a semi-formed steel cage integral molded structure provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: support frame 3 Including the first support bar 31, the second support bar 32 and the third support bar 33, the first support bar 31 is in a "U" shape, the second support bar 32 and the third support bar 33 are arranged on both sides of the first support bar 31 free ends, and set in opposite directions; the support frame 3 is an integrally formed structure.

[0028] Through the above further improvements, this embodiment has the following advantages compared with the prior art: the setting of multiple support points and integrally formed structure improves the overall support force of the support frame 3 and also improves the connection strength of the reinforcement cage .

Embodiment 3

[0030] see Figure 4-6 , the figure shows a semi-formed reinforcement cage integral mold structure provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: positioning plate 4 Including the chassis 41 and the first positioning groove 42 and the second positioning groove 43 arranged on the chassis 41, the first positioning groove 42 and the second positioning groove 43 are vertically arranged, and the first positioning groove 42 is lower than the second positioning groove 43 The widths of the first positioning groove 42 and the second positioning groove 43 are larger than the outer diameters of the first bottom reinforcing bar 12 and the second bottom reinforcing bar 22 ;

[0031] Through the above-mentioned further improvement, this embodiment has the following advantages compared with the prior art: a positioning plate 4 can simultaneously position the first botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com