Magnesium alloy construction member step temperature forming method

A step temperature, magnesium alloy technology, applied in metal processing equipment and other directions, can solve the problems of high raw material requirements, limited application of magnesium alloys, and high manufacturing costs, achieve the coordination and unity of forming and toughening, realize comprehensive utilization of thermal energy, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

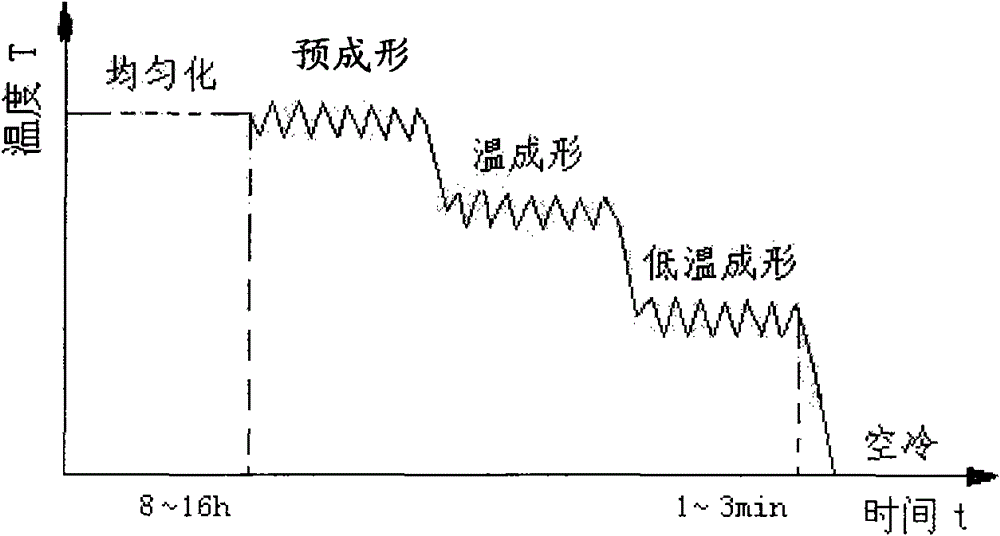

[0019] The stepwise temperature forming process route of magnesium alloy is: blanking of magnesium alloy cast rod - surface turning - homogenization treatment - upsetting preforming - warm forming - low temperature forming.

[0020] (1) Raw materials: domestically marketed magnesium alloys AZ31, AZ80, AZ91, ZK60, etc., which are produced on the existing semi-continuous casting production line, and the size range of cast rods is φ60-500.

[0021] (2) Deformation conditions for direct upsetting of magnesium alloy at homogenization temperature: ① Controlled compression deformation, strain rate at (1~6)×10 -1 ; When the strain rate increases, use "micro-intermittent" compression deformation; when the compression amount is 20%, the interval is 2-3 seconds; ②Reduce friction: one is paper oil-based graphite lubricating material to reduce friction resistance; The temperature of the tool makes the preheating temperature of the upper and lower templates 20-40°C higher than that of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com