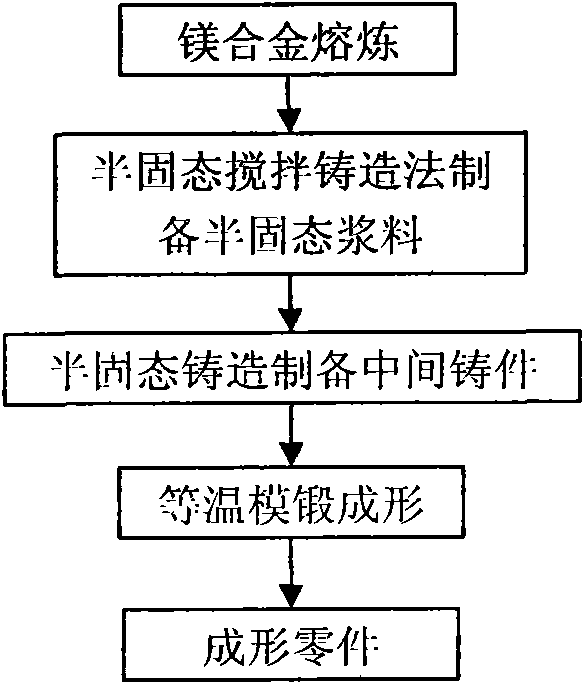

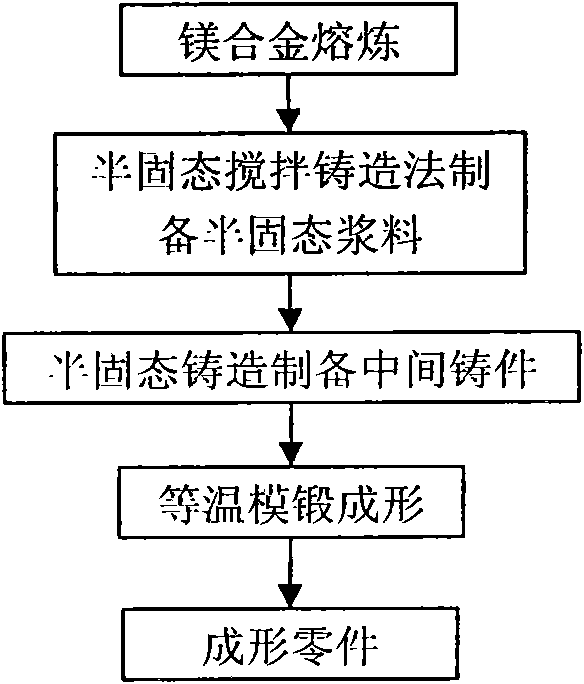

Dual-controlled composite forming method for casting and forging of magnesium alloy

A composite forming and magnesium alloy technology, applied in the field of dual-control composite forming of magnesium alloy casting and forging, can solve the problems of difficulty in obtaining fine non-dendritic solid phase, inability to refine grains, difficult product performance, etc., and achieve product quality High, good material formability, high dimensional accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The ZK60 magnesium alloy is smelted in a resistance heating furnace. After degassing and slag removal, the temperature is lowered to 580 ° C. The whole melting process is carried out under N 2 +6% SF 6 Carry out under a protective atmosphere; then, carry out electromagnetic stirring on the melt, uniform temperature distribution of the melt, and break dendrites; cool and solidify in the forming mold to obtain a casting as a forging forming blank; heat the casting to the solid phase of ZK60 magnesium alloy 5-10°C above the linear temperature (ZK60 solidus temperature is 426°C) and keep warm for 5 minutes, place it in a forging forming mold; forge and form at a deformation rate of 1s-1.

Embodiment 2

[0022] The AZ31 magnesium alloy is smelted in a resistance melting furnace. After degassing and slag removal, the temperature is lowered to 580°C. The whole smelting process is covered with N 2 +6% SF 6 Carried out under a protective atmosphere; then, the melt is mechanically stirred to uniform the temperature distribution of the melt, and the dendrites are broken; cooling and solidifying in the forming mold to obtain a casting, which is used as a forging blank; heating the casting to the solid phase of AZ31 magnesium alloy 2-5°C above the linear temperature (the solidus temperature of AZ31 magnesium alloy is 566°C) and keep warm for 5 minutes, then place it in the forging mold; take 10s -1 Deformation rate forging forming.

[0023] In the present invention, by changing the type of magnesium alloy, the casting and forging dual-control composite forming method can be used to prepare magnesium alloy products with relatively complex shapes and excellent performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com