Semicanal formation rolling machine

A rolling mill and tube forming technology, applied in the field of rolling mills and semi-pipe special rolling mills, can solve the problems of difficult control of semi-pipe product parameters, low production efficiency, lack of half-pipes, etc., achieve low rigidity, reduce equipment manufacturing costs, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

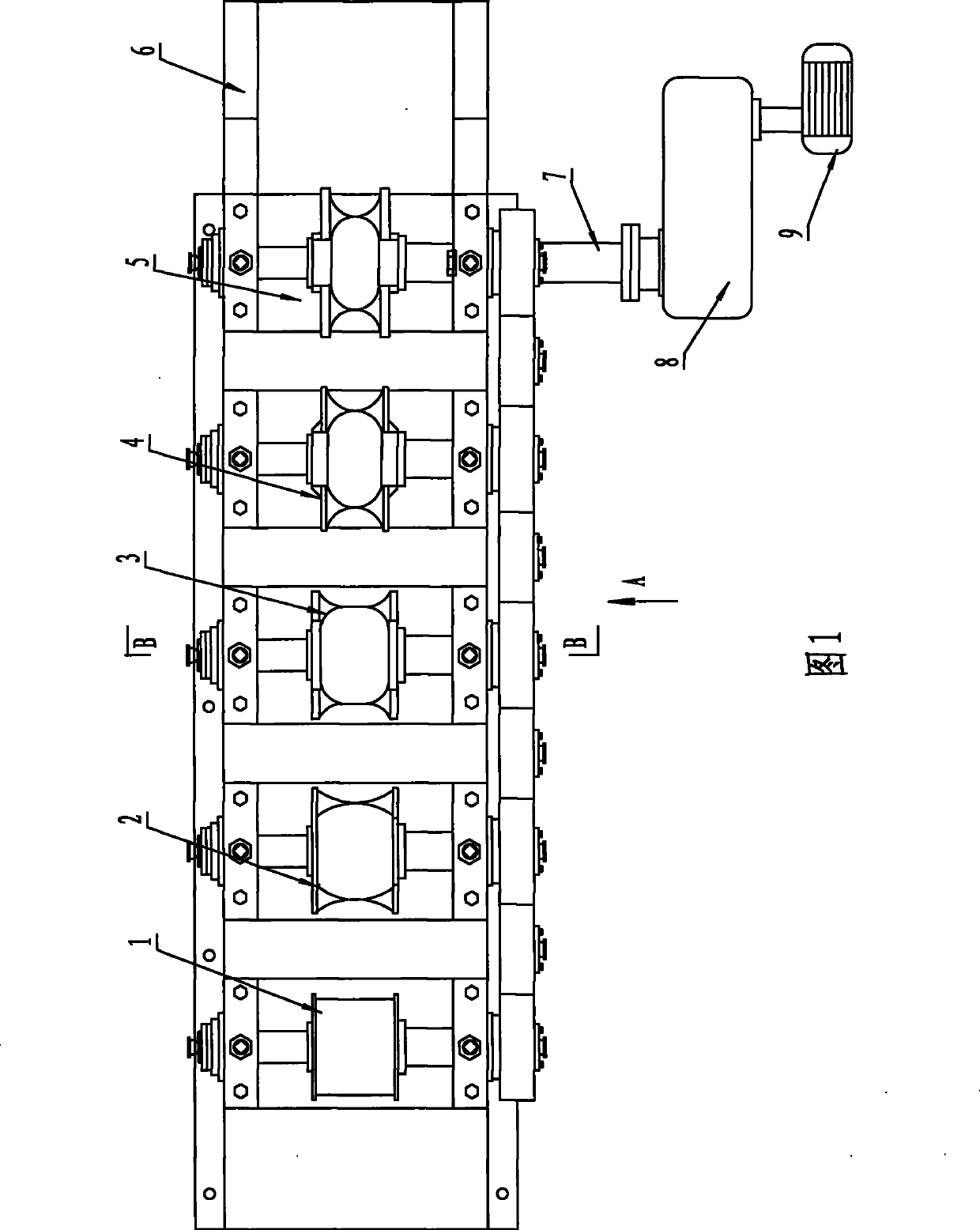

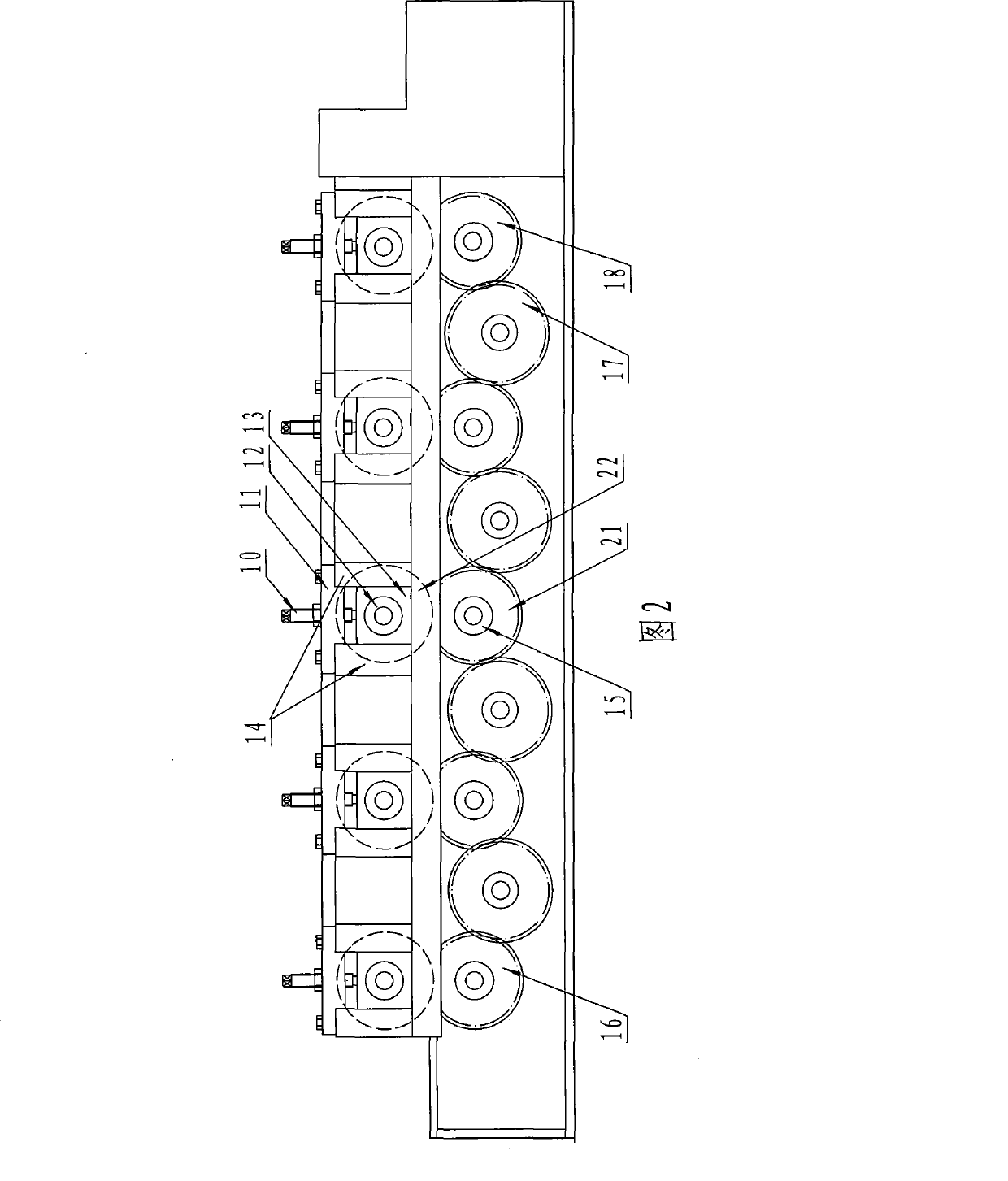

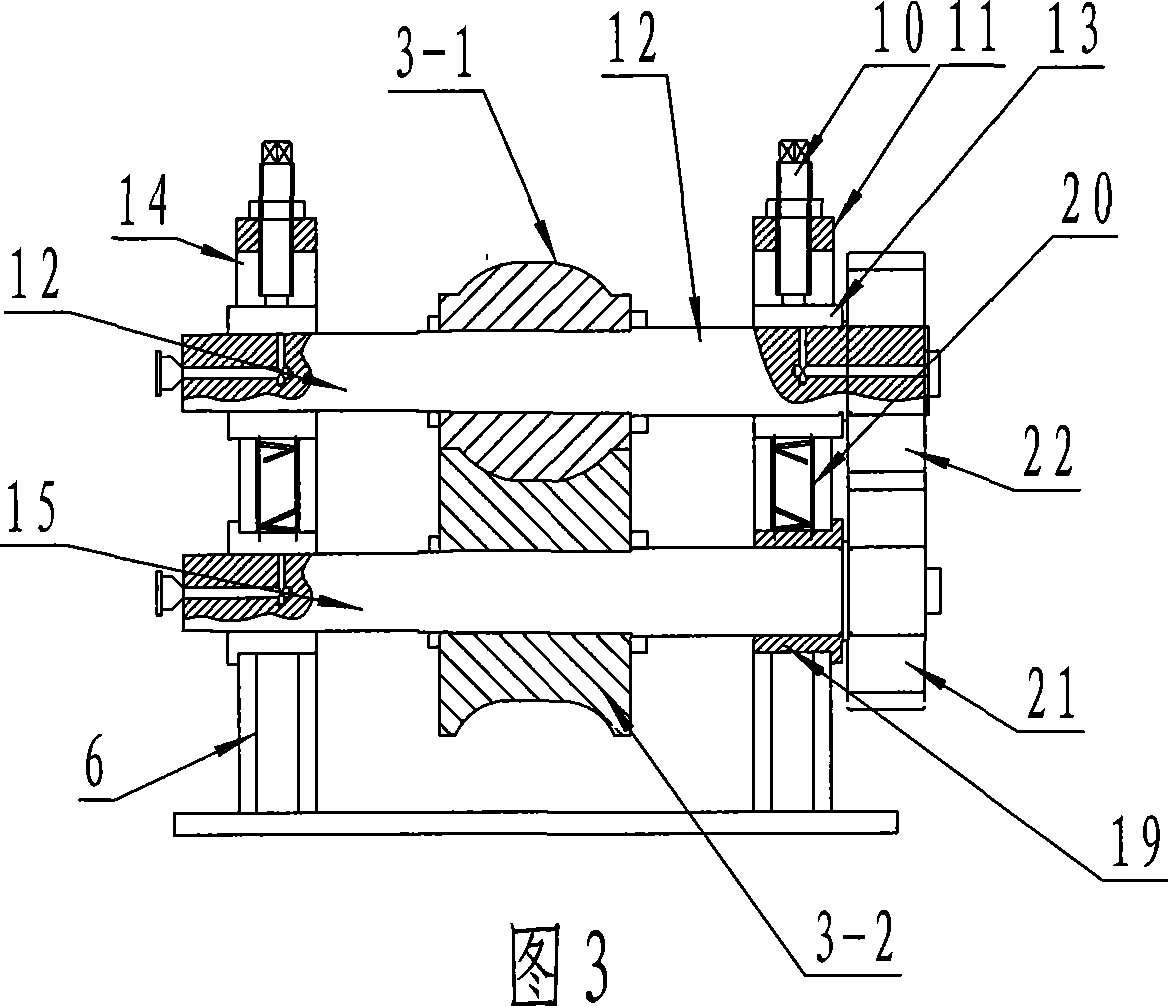

[0019] Referring to Fig. 2, the present invention comprises a machine base 6, the lower part of the machine base is provided with a transmission part, and the upper part of the machine base is provided with a rolling part and a pressing adjustment mechanism. The core technology of the present invention is the rolling part. Referring to Fig. 1, the rolling part is composed of a guide pair of rolls 1, a preliminary forming pair of rolls 2, a semi-formed pair of rolls 3, a forming pair of rolls 4 and a rolling pair of rolls 5 arranged in sequence, The rolled steel strip enters from the guide pair of rolls, is rolled step by step by the preliminary forming pair of rolls, semi-formed pair of rolls, and formed pair of rolls, and is rolled out by the rolling pair of rollers, and the finished half pipe is rolled out at one time. see Figure 4-13 , the upper and lower rolls 1-1 and 1-2 of the guiding pair of rollers are cylindrical rollers, and the remaining upper rollers of the prelim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com