Stator core with winding for medium-sized low-voltage variable-frequency motor

A frequency conversion motor and stator core technology, applied in windings, electric components, manufacturing of motor generators, etc., can solve the problems of increasing the capacity of the frequency converter, easy collision of paint films, short-circuit faults between turns, etc., to improve dv/dt value, good insulation performance between turns, and the effect of improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

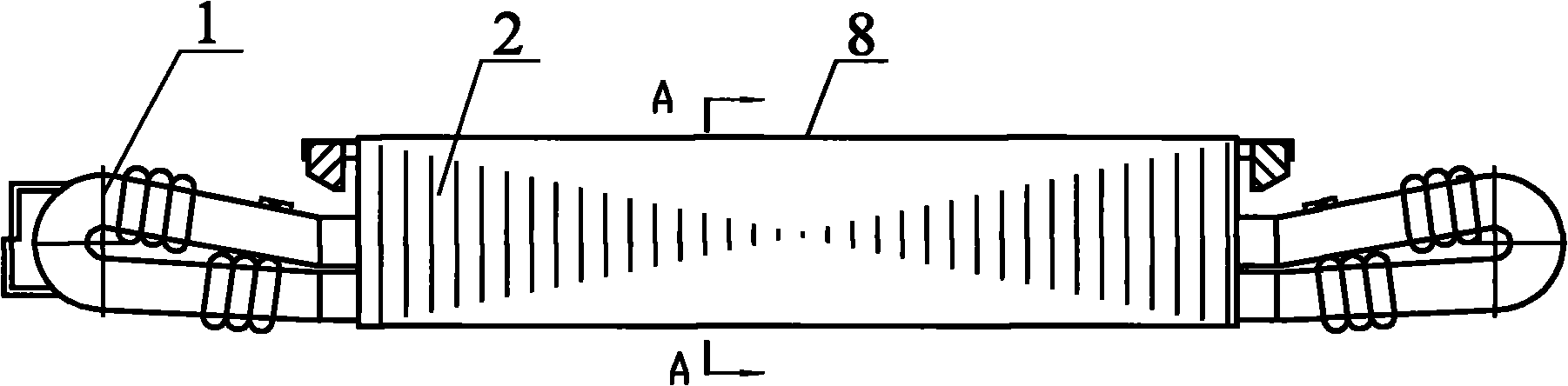

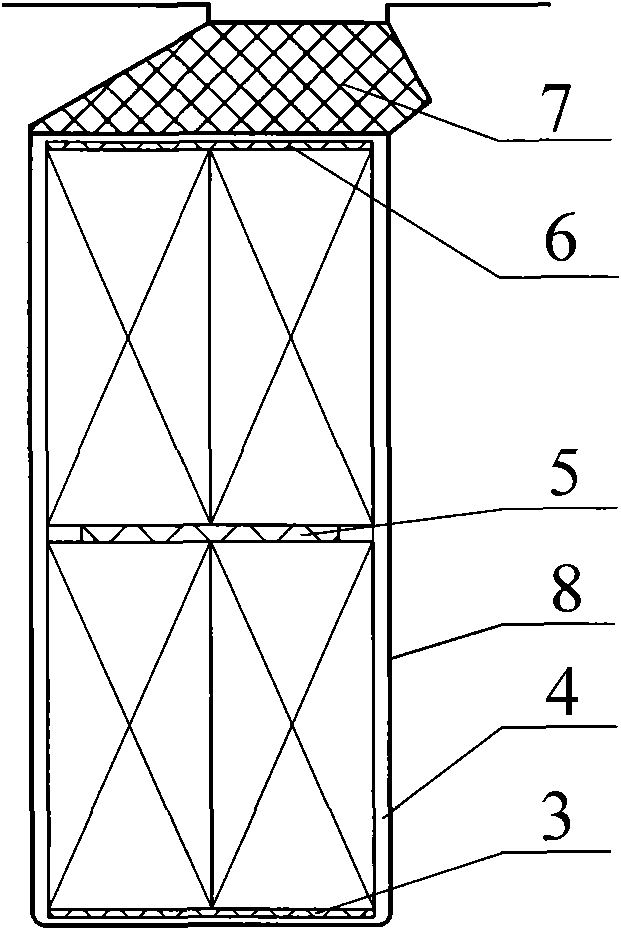

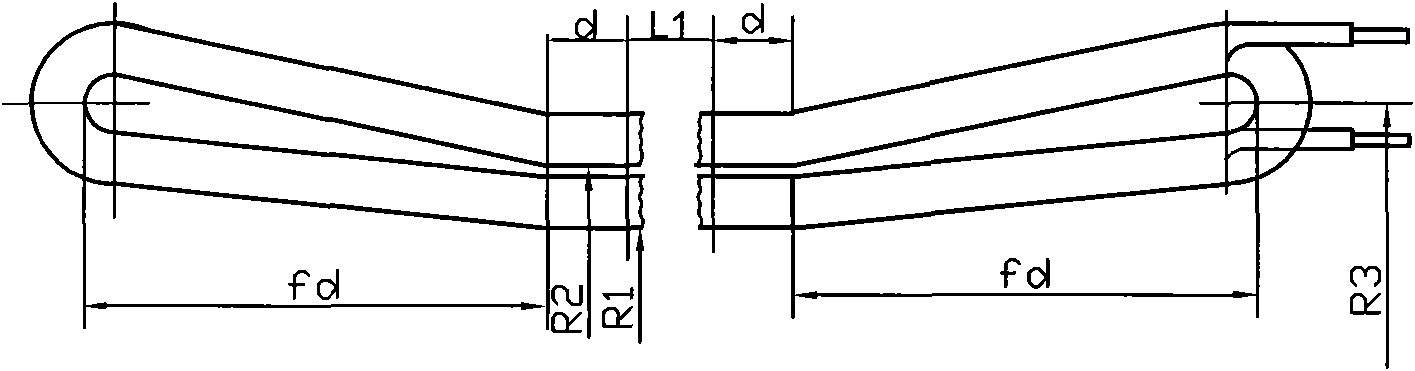

[0014] As shown in the figure: the present invention is mainly composed of semi-formed winding 1, semi-open slot stator punching sheet 2, bottom pad 3, slot body insulation layer 4, middle pad 5, adjustment pad 6, slot wedge 7 and installation slot body 8, etc. .

[0015] The medium-sized low-voltage frequency conversion motor has a winding stator core, including semi-formed winding 1, half-open slot stator punching plate 2, bottom pad 3, slot body insulation layer 4, middle pad 5, adjustment pad 6, slot wedge 7 and installation slot body 8. The semi-formed winding 1 is installed at both ends of the installation tank 8, the top of the installation tank 8 is open, and the installation tank 8 is provided with a tank insulation layer 4 that matches the shape of the cavity. In the tank insulation layer 4 Place the bottom pad 3 on the bottom layer of the cavity, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com