Scraper-type semi-forming casting mould

A technology of molds and brackets, applied in the field of scraper type semi-formed casting molds, can solve the problems of increasing machining workload, increasing production costs, wasting raw materials, etc., and achieves the effects of simple structure, cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

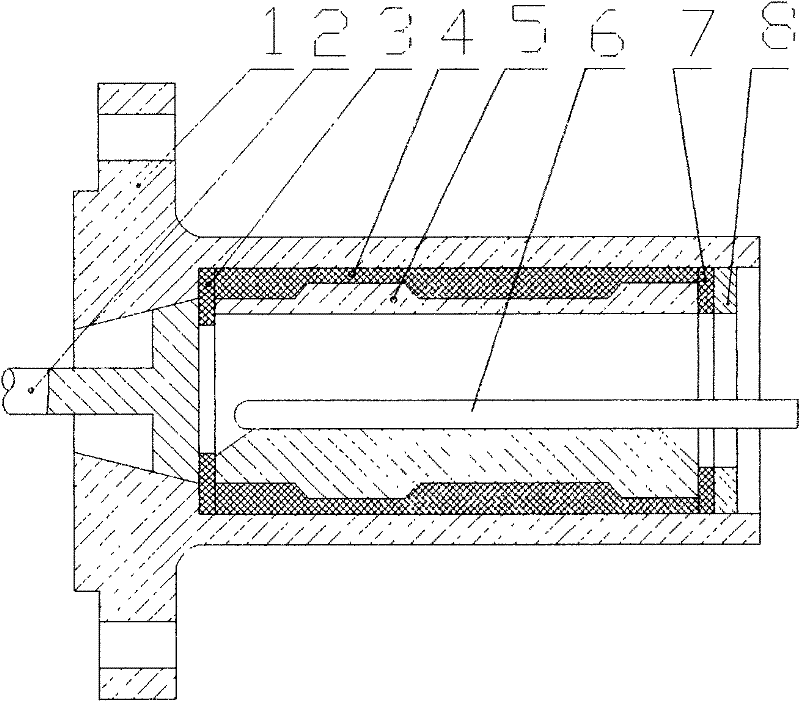

[0012] As shown in the figure, the scraper type semi-formed pouring mold includes a casting mold 1, a rear push plate 2, a rear sand plate 3, a semi-formed sand shell 4, a casting 5, a bracket plate 6, a front sand plate 7, and a front iron plate 8. Install the rear push plate 2, the rear sand plate 3, the front sand plate 7 and the front iron plate 8 in the inner cavity of the casting mold 1, after injecting the molding sand in the inner cavity of the casting mold 1, turn on the motor to make the casting mold 1 rotate, and the bracket plate extends into the cavity of the casting mold 1 After scraping the molding sand into shape, withdraw from the bracket 6 and pour molten iron.

[0013] In the scraper type semi-formed pouring mold of the present invention, push plate 2 and rear sand plate 3 and front sand plate 7 and front iron plate 8 are installed in the inner cavity of casting mold 1 .

[0014] In the scraper type semi-formed pouring mold of the present invention, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com