Jewelry manufacturing method based on wax dropping

A production method and technology for jewelry, applied in clothing, manufacturing tools, applications, etc., can solve the problems of ambiguous detailed design, inability to carry out complex layers, rough modeling surface, etc., achieve moderate fluidity, facilitate wax carving molding, improve The effect of finished product quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

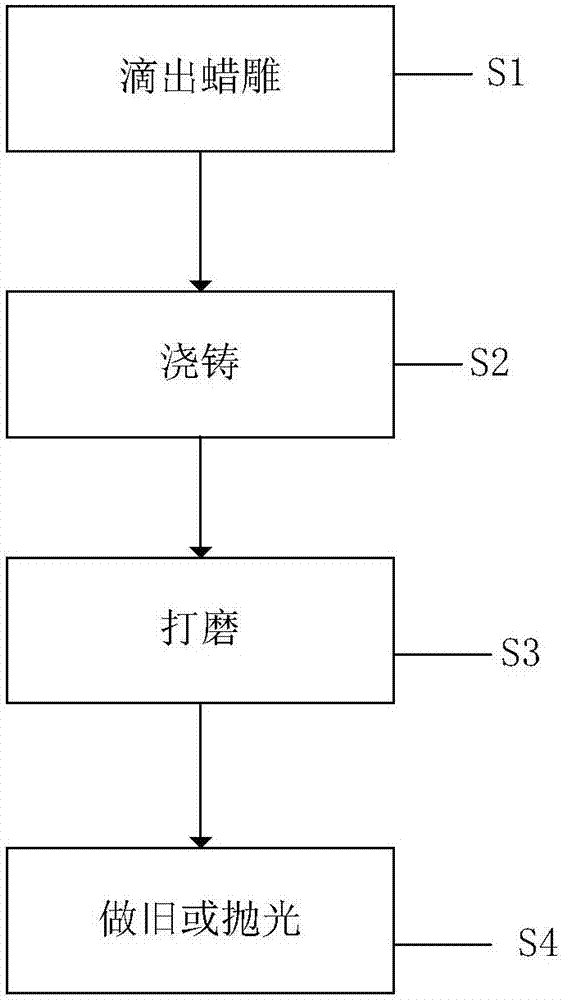

[0018] Please refer to figure 1 , the embodiment of the present invention provides a kind of jewelry making method based on drop wax, comprises the following steps:

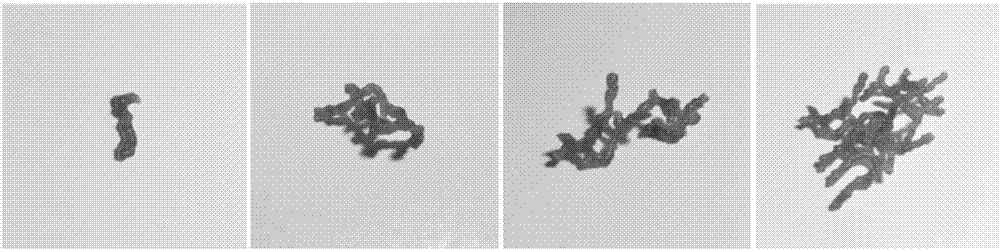

[0019] S1. Select the wax raw material and melt the wax raw material with an electric soldering iron. The electric soldering iron uses the melted wax raw material to drip out the wax sculpture. The shape of the wax sculpture matches the shape of the jewelry.

[0020] The temperature of the soldering iron plays an important factor in determining the lines of the wax sculpture. If the temperature of the soldering iron is too high, the fluidity of the wax will be stronger, and the dripping lines will be thicker. At the same time, the temperature of the wax will not drop rapidly, making it diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com