container manufacturing

A technology of molds and products, which is applied in the field of molding technology of plastic products, and can solve problems such as the limitation of flexibility of fuel tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

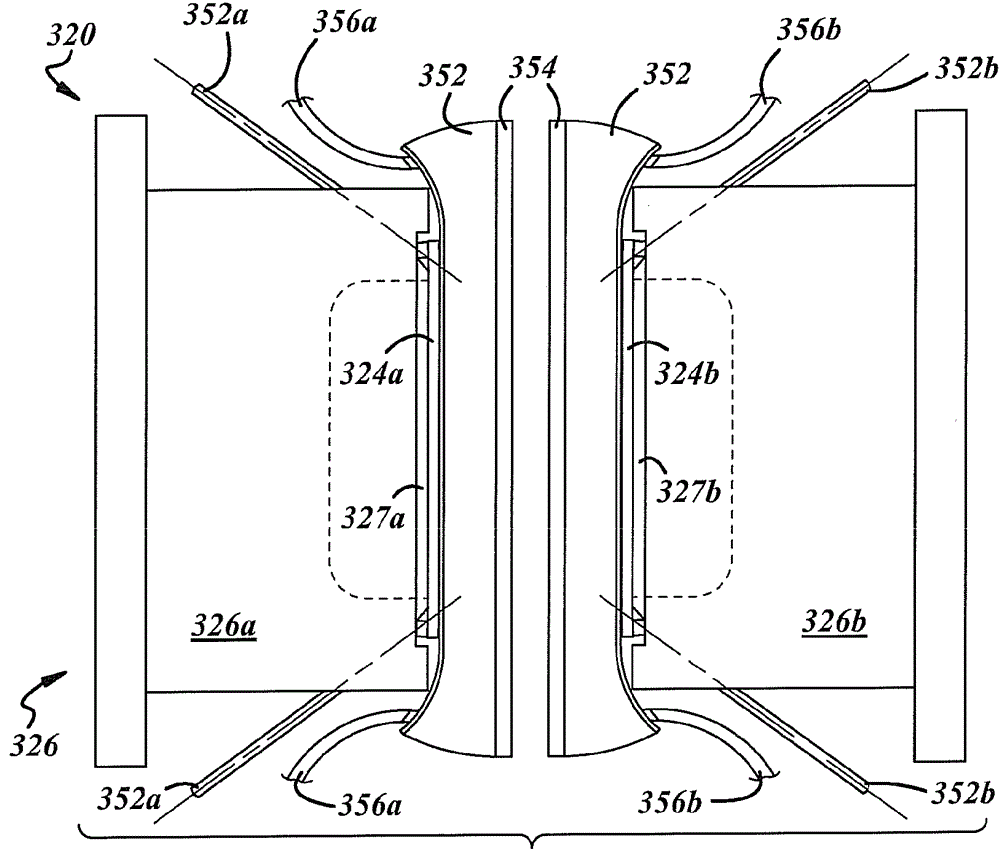

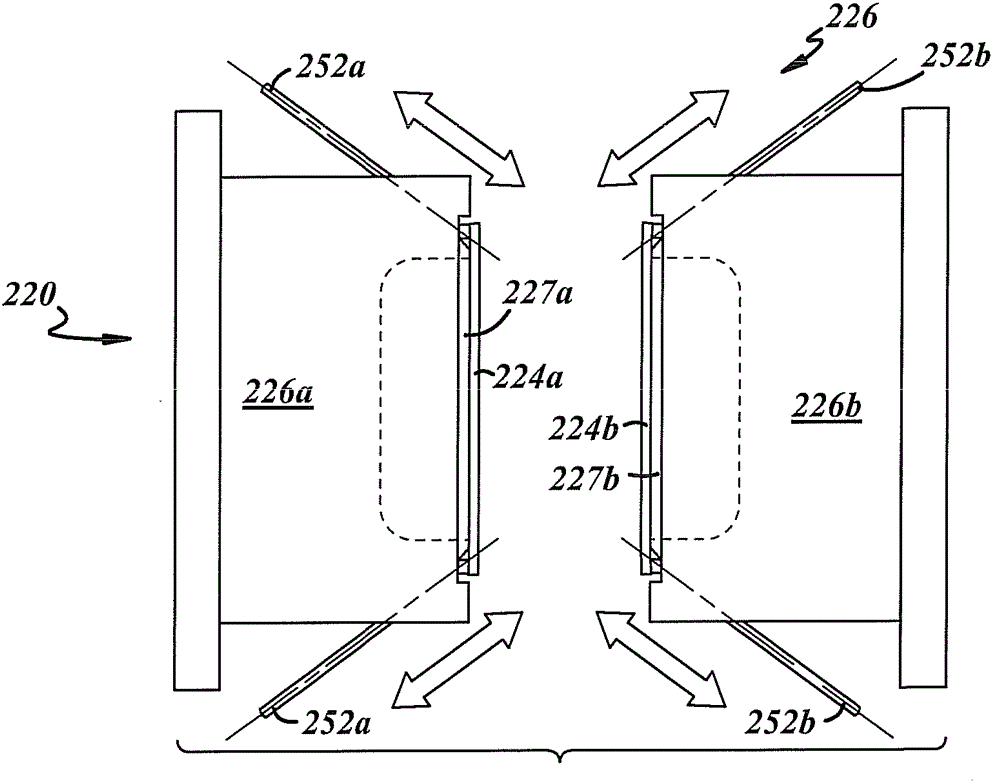

[0030] See the attached drawings in more detail, figure 1 An exemplary embodiment of the mold forming apparatus 20 is described, which can be used to implement the method of manufacturing a single-layer or multi-layer plastic product (such as a plastic fuel tank) of the present disclosure. During the manufacturing of the product, one or more The components are introduced into the product. The following device description only provides a brief overview of an exemplary device, but other devices not shown here can also support the currently disclosed method.

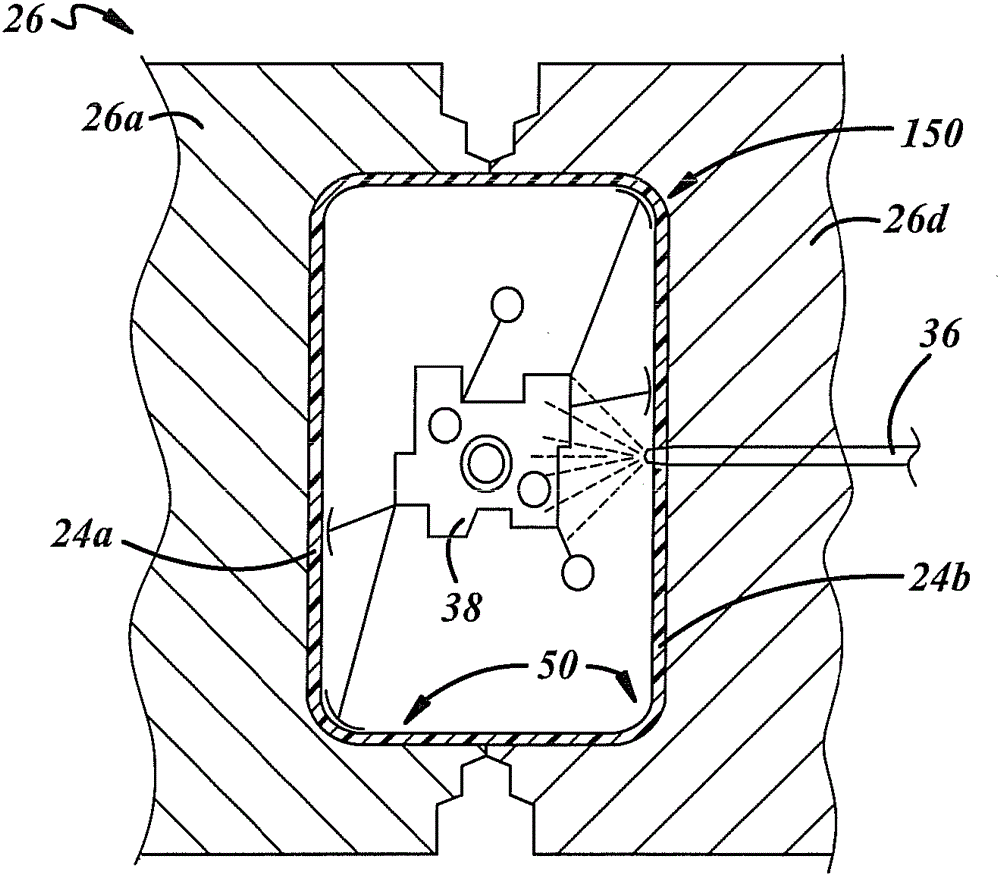

[0031] Generally speaking, the equipment 20 may include an extruder 22 for producing the parison 24, and a die 26 of a blow molding and / or deep drawing machine to form the parison 24 into a product, such as a fuel tank (not shown) , And the mold includes substantially opposed mold halves 26a, 26b. As used herein, the term "mold half" can include a single component or a multi-component assembly. In other words, each mold half...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com