A Physical Modeling Method for Axial Thermal Error of CNC Machine Tool Spindle

A modeling method and technology of CNC machine tools, applied in the directions of simulator, program control, computer control, etc., can solve the problems of increasing compensation cost, multi-sensor, affecting actual processing, etc., to achieve convenient post-compensation, strong generalization ability, and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A physical modeling method for axial thermal error of a numerically controlled machine tool spindle provided in this embodiment includes the following steps:

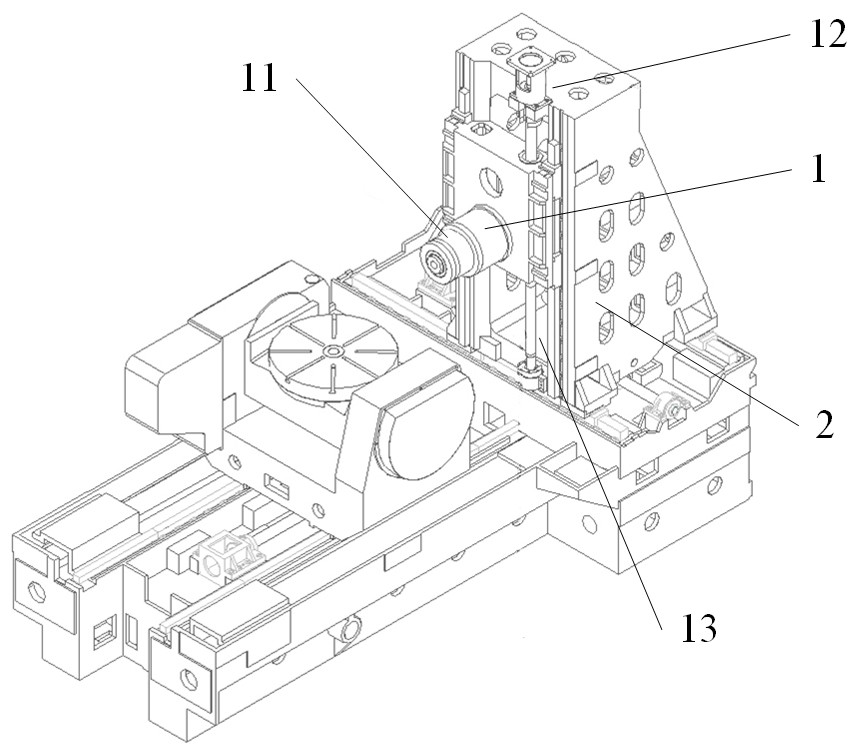

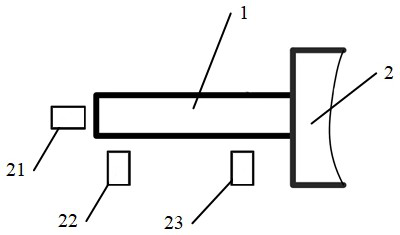

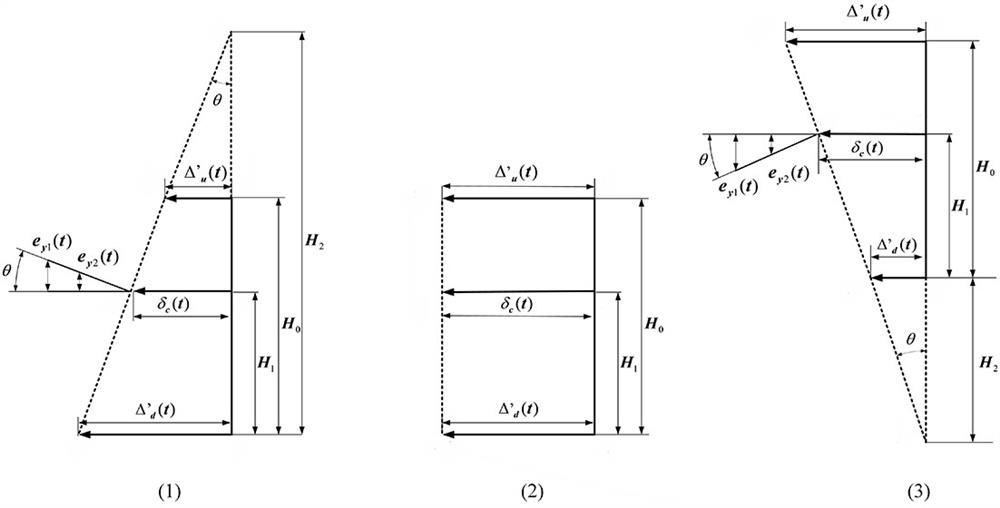

[0045] (A) Install a temperature sensor on the machine tool, the temperature sensor includes 4, which are used to measure the temperature T of the spindle 1 S The first temperature sensor is used to measure the temperature T of the upper part of the column 2 C1 The second temperature sensor is used to measure the temperature T of the lower part of the column 2 C2 The third temperature sensor and used to measure the ambient temperature T amb The fourth temperature sensor, such as figure 1 As shown, the installation location 11 of the first temperature sensor, the installation location 12 of the second temperature sensor, the installation location 13 of the third temperature sensor, and the installation location of the fourth temperature sensor is installed on a fixture near the machine tool, such as on a wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com