Flow stabilizing and pressurizing device of evaporator

A technology of supercharging device and evaporator, which is applied in the direction of modification using liquid cooling, cooling/ventilation/heating modification, electrical components, etc., which can solve the problem of affecting the use efficiency, unable to meet the needs of heat dissipation of high heat flux electronic components, disturbing water circulation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

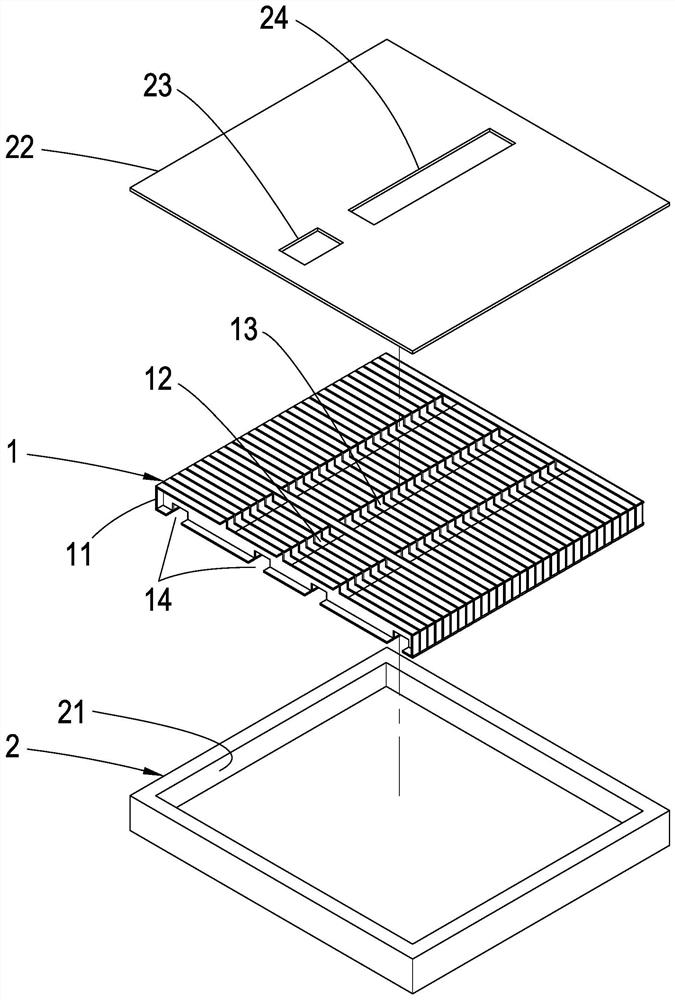

[0061] see Figure 1~Figure 2 , are respectively the three-dimensional schematic diagram of the steady-flow booster device of the evaporator of the present invention and the schematic cross-sectional view of the internal structure. As shown in the figure, it is the first embodiment of the overall structural configuration of the present invention, which at least includes a heat dissipation module 1 and a housing 2 ;

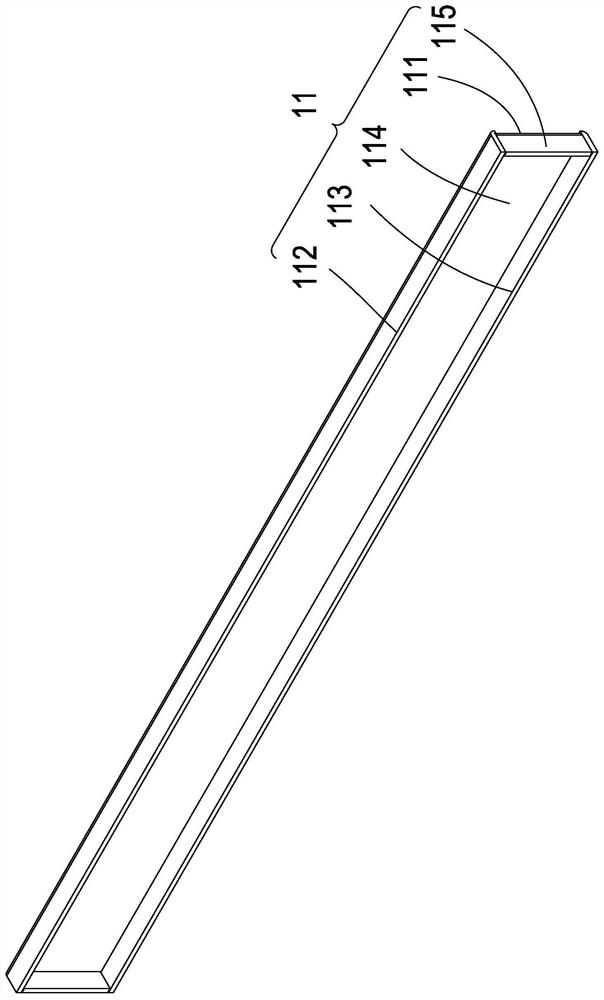

[0062]Wherein, the heat dissipation module 1 is formed by stacking and assembling a large number of heat dissipation components 11 continuously. . The second plate surface 112 and the third plate surface 113 are integrally formed or fixed to each other, so that a semi-open inner flow channel 114 is formed inside the heat dissipation assembly 11 . A fourth plate surface 115 is respectively provided at both ends, and a water inlet 12 and an air outlet 13 that are not connected to the outside are respectively opened on the heat dissipation module 1 (that is, some of...

no. 3 example

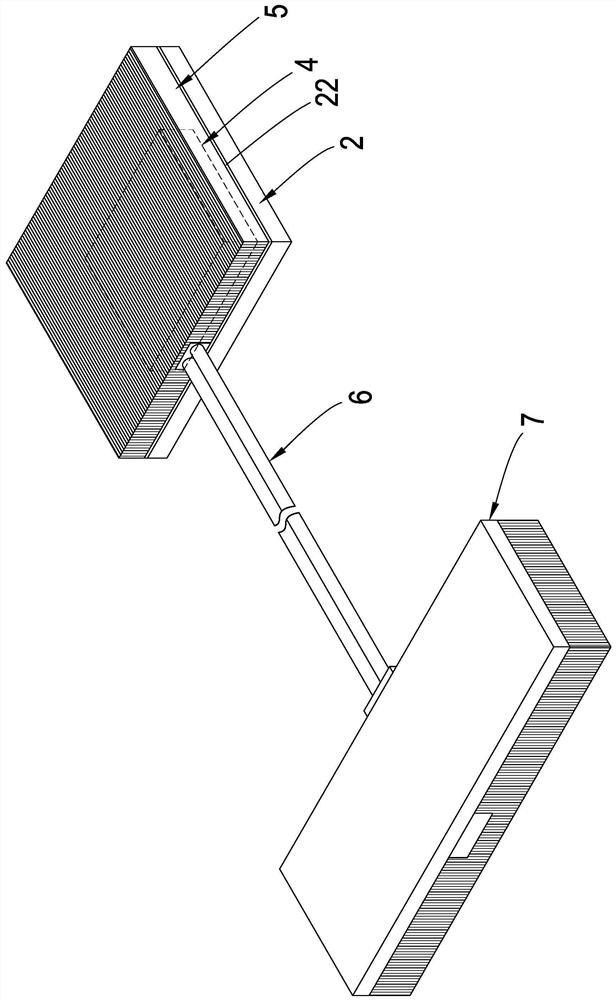

[0070] see Figure 11 , is the third embodiment of the overall structural configuration of the present invention. This embodiment continues the second embodiment. In this embodiment, there is a predetermined space between the two ends of each heat dissipation component 11 and the inner surface of the chamber 21, and each The blocking blocks 3 are arranged on the side of the outer cover 22 opposite to the chamber. When the outer cover 22 is closed on the chamber 21, each blocking block 3 is placed between the two ends of the heat dissipation assembly 11 and the chamber 21. between the inner sides, and each heat dissipation assembly 11 uses the half block form of the second to sixth embodiments (equivalent to Figure 8A , Figure 8B , Figure 8C , Figure 8D , Figure 8E , the second embodiment is used in the figure), and a gap 31 is opened at the two ends of the blocking block 3 relative to each inner flow channel 114, and the gap 31 maintains a space for liquid water or ga...

no. 5 example

[0072] see Figure 14 , Figure 15 , is the fifth embodiment of the overall structural configuration of the present invention. In this embodiment, there is a predetermined space between the two ends of each heat dissipation assembly 11 and the inner surface of the chamber 21, and each heat dissipation assembly 11 is used equivalent to Figure 8D In the half-block form of the fifth embodiment, the protruding section 116 can be located between the two ends of the heat dissipation assembly 11 and the inner surface of the housing chamber 21, and each fourth plate surface 115 is blocked on both sides of each inner flow channel 114. Above the end, the water inlet 12 is set at the position corresponding to the top of each protruding section 116, and the liquid water passes through the water inlet 23, the water inlet 12 in sequence, and enters the inner runners 114 through the bottom of each fourth plate surface 115 , and then circulate through each channel 14 to various places in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com