Lifting pot

A lifting device and synchronous lifting technology, which is applied in the field of lifting pots, can solve the problems of small application range, high cost, and inconvenient cleaning, and achieve the effects of simple and reasonable structural design, reduced volume and cost, and increased use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

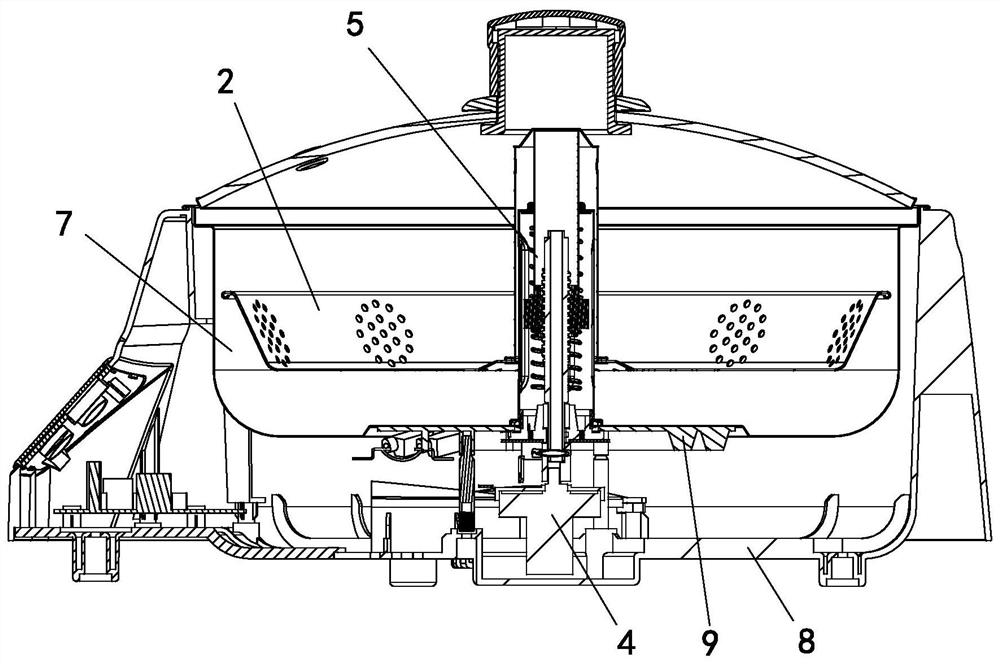

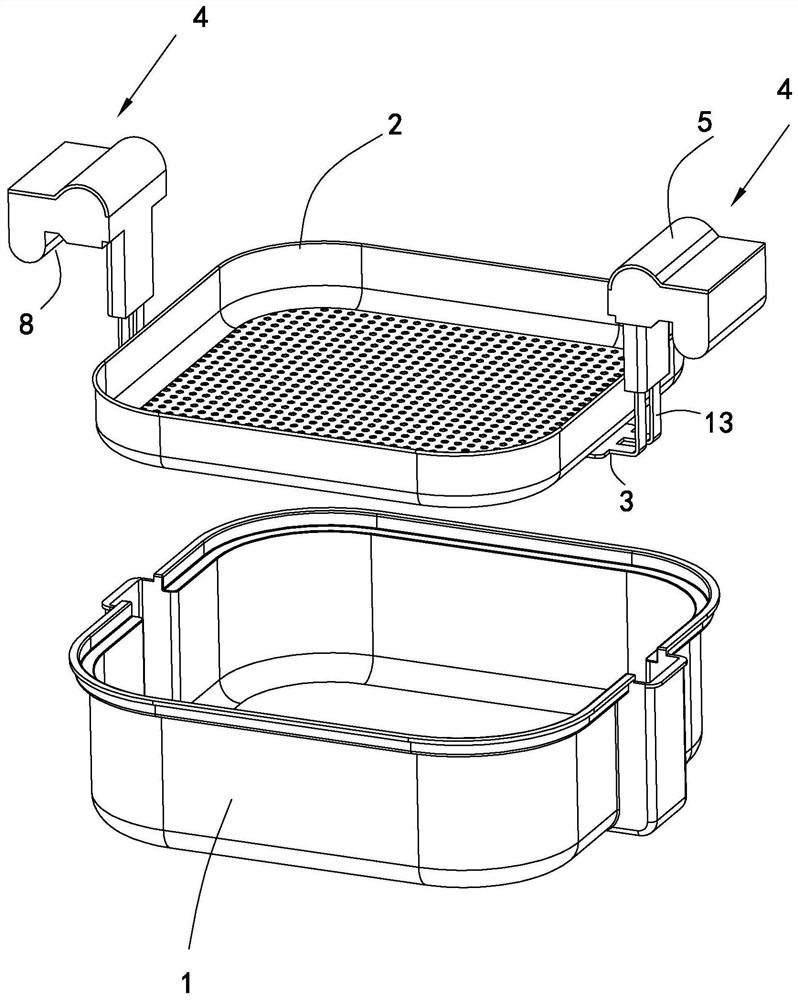

[0024] Embodiment 1, combining Figure 2 to Figure 4 , a lifting chafing dish, comprising a pot body 1 and a drain pan 2, the drain pan is arranged in the inner cavity of the pot body, and a hook bar 3 with holes is provided on the outside of the side wall of the drain pan 2, and the pot body 1 provides heating functions, such as electric heating, carbon Heated by fire or gas, the pot body heats the soup in the inner cavity and the food in the drain pan. The two ends of the drain pan 2 are respectively provided with a lifting device 4, and the lifting device 4 includes a housing 5 and a driving device arranged in the housing. 6 and lifter 7. The shell 5 is formed with a hooking part 8, which is hung on the top port of the pot body 1. Of course, the hooking part 8 can also be seated on the top port of the pot body 1, just extend the top port of the pot body 1 by a fold Side, hooking part 8 just can sit and be located at pot body top port, and housing 8 can support drain pan we...

Embodiment 2

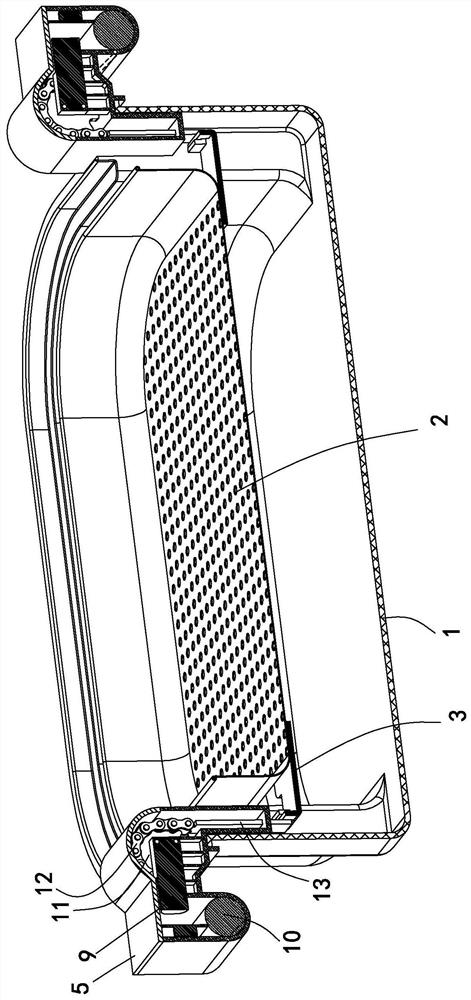

[0027] Example 2, combined with Figure 5 , the difference between embodiment 2 and embodiment 1 is that the structure of the lifting member 7 is different, and the others are consistent. Suspender 13, screw rod 11 is threadedly connected with bevel gear 12, the other end of suspender 13 passes through housing 5, and the end of suspender 13 is provided with hook 14, and hook 14 is hooked in the hole of hook bar 3, and the motor 9 Drive shaft end is also provided with active bevel gear 15, and active bevel gear 15 drives bevel gear 12 to rotate, and bevel gear rotates and drives screw rod lifting, realizes boom synchronous lifting thereby realizes drain pan 2 lifting in pot body 1.

Embodiment 3

[0028] Example 3, combined with Figure 6 The difference between embodiment 3 and embodiment 1 is that the structure of the lifting member is different, and the others are the same. The lifting member 7 includes a rack 11 and a boom 13. One end of the rack 11 is connected to the boom 13, and the boom 13 The other end of 13 passes through the housing 5, the end of the suspension rod 13 is provided with a hook 14, and the hook 14 is hooked in the hole of the hook bar 3, the transmission shaft of the motor 9 is provided with a gear 15, and the gear 15 drives the rack 11 up and down, Realize the synchronous lifting of the suspension rod 13 so as to realize the lifting of the drain pan 2 in the pot body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com