A Method for Preventing Corner Cracks of Billet Bulb Flat Steel Continuous Casting Billet

A corner crack and bulb flat steel technology, which is applied in the field of billet bulb flat steel production, can solve the problems of serious corner cracks, inability to deal with defects, and rejection of cast slabs, and achieve the effect of reducing sensitive rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

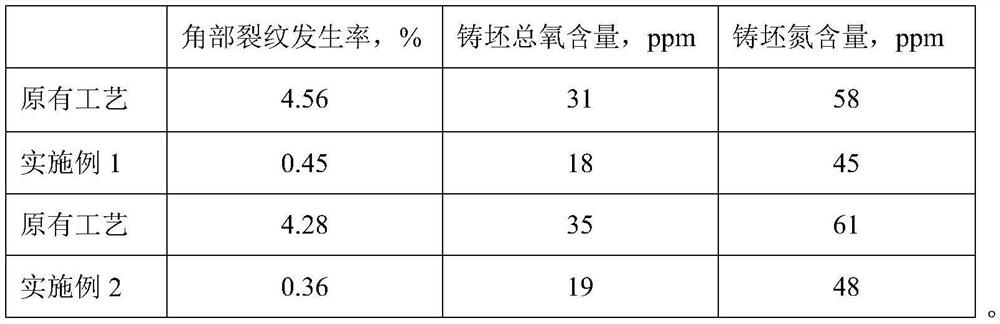

Embodiment 1

[0040] The casting section is AH32 flat bulb steel with a cross section of 180mm×180mm. The specific process is as follows:

[0041] S1: The temperature of molten steel AH32 of bulb flat steel is adjusted before pouring in the LF furnace, so that the superheat of molten steel in the tundish before pouring is kept at 35 °C; during the temperature adjustment process in the LF furnace, the temperature in the LF furnace is adjusted to In the state of slight positive pressure, the pressure difference inside and outside the furnace is maintained at 0.03MPa; during the LF heating process, 35kg of calcium carbide slag is added per 100 tons of molten steel.

[0042] S2: After adjusting the molten steel temperature to be 6°C higher than the target temperature set by the upper machine, the molten steel is subjected to bottom blowing argon and weak stirring for 3.5 minutes.

[0043] S3: The mold copper tube with an inverted taper of 0.75% / m is used, the vibration frequency of the mold is ...

Embodiment 2

[0052] The casting section is AH32 flat bulb steel with a cross section of 150mm×150mm. The specific process is as follows:

[0053] S1: The temperature of molten steel AH32 for bulb flat steel is adjusted before pouring in the LF furnace, so that the superheat of molten steel in the tundish before pouring is kept at 40 °C; during the temperature adjustment process in the LF furnace, the temperature in the LF furnace is adjusted to In a slightly positive pressure state, the pressure difference inside and outside the furnace is maintained at 0.02MPa; during the LF heating process, 40kg of calcium carbide slag is added to every 100 tons of molten steel.

[0054] S2: After adjusting the molten steel temperature to be 8°C higher than the target temperature set by the upper machine, the molten steel is subjected to bottom blowing argon and weak stirring for 4 minutes.

[0055] S3: The mold copper tube with an inverted taper of 0.65% / m is used, the vibration frequency of the mold is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com