Cementing material for modifying bulk filling body as well as preparation method and application of cementing material

A technology for a gelling material and a filling material, which is applied in the field of bulk filler-modified gelling material and its preparation, and achieves the effects of simple raw material ratio, high early strength, and easy-to-obtain raw material ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

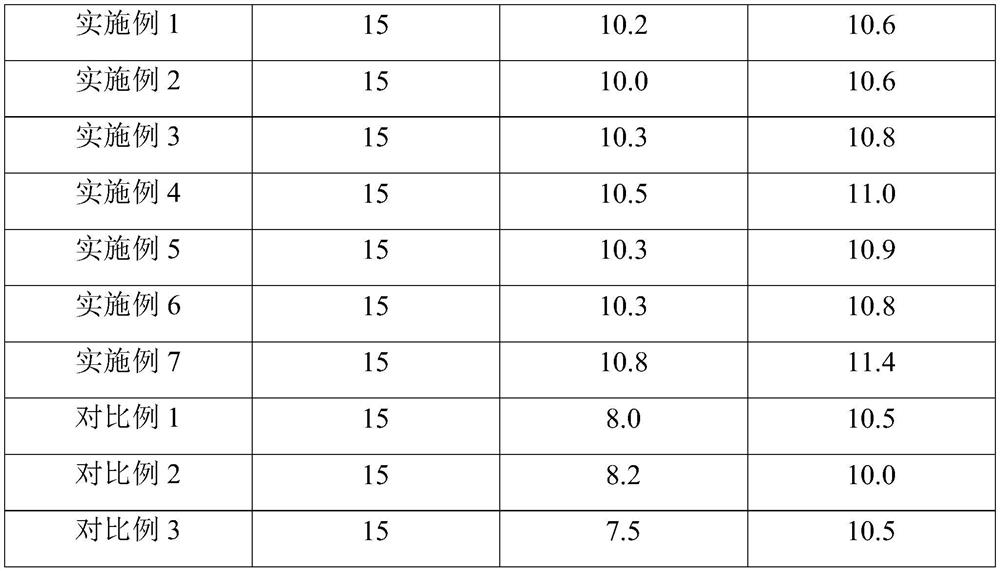

Examples

Embodiment 1

[0025] A gelation material for scattered filling body, including the following mass percent components: 5% cement clinker, 85% of slag powder and 10% of desulfurized plaster powder.

[0026] The slag powder includes 34% calcium oxide by mass, 12% magnesium oxide, 34% of silica, and 3% of trioxide, and trioxide; the mine flour is quenched, dried. , Slag powder formed by breaking the powder, which has a particle size of 40-50 μm.

[0027] The mass content of the calcium sulfate in desulfurized plaster powder is 90%;

[0028] Cement clinker includes 60% calcium oxide by mass, 5% magnesium oxide, 25% of silica, and 4% of ferric dioxide.

[0029] The method for preparing the cement-modified gelation material is: the above cement clinker, the slag powder and the desulfurized plaster powder are mixed evenly after the above mass percentage.

[0030] Coal gangue filling material was prepared by the gelation material, which was composed of the above-described gelation material, coal gangue ...

Embodiment 2

[0034] A gelling material for scattered filling body, including the following mass percent components: 20% cement clinker, 77% of slag powder and 3% of desulfurized plaster powder.

[0035] The slag powder includes 38% calcium oxide by mass, 10% magnesium oxide, 31% of silica, 31%, tri-aluminum, and triodoxide by 5%; the mine flour is quenched, dried , Slag powder formed by breaking the powder, which has a particle size of 40-50 μm.

[0036] The mass content of the calcium sulfate in desulfurized plaster powder is 95%;

[0037] Cement clinker includes 65% calcium oxide, 3% magnesium oxide, 23% of silica, and 3% of ferric oxide, 3%, 3% of silica.

[0038]The method for preparing the cement-modified gelation material is: the above cement clinker, the slag powder and the desulfurized plaster powder are mixed evenly after the above mass percentage.

[0039] Coal gangue filling material was prepared by the gelation material, which consists of the above-described gelation material, coal...

Embodiment 3

[0043] A gelation material for scattered filling body, including the following mass percent components: 40% of cement clinker, 84% of slag powder and 6% of dethinated plaster powder.

[0044] The slag powder includes 37% calcium oxide according to the mass percent, 11% magnesium oxide, 32% of silica, and 5% of triodoxide, and triodoxide; the slag powder is quenched, drying the granulated blast furnace slag , Slag powder formed by breaking the powder, which has a particle size of 40-50 μm.

[0045] The mass content of the calcium sulfate in desulfurized plaster powder is 99%;

[0046] Cement clinker includes 63% calcium oxide by mass, 4% magnesium oxide, 24% silica, and 4% of triodoxide.

[0047] The method for preparing the cement-modified gelation material is: the above cement clinker, the slag powder and the desulfurized plaster powder are mixed evenly after the above mass percentage.

[0048] Coal gangue filling material was prepared by the gelation material, which consists of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com