A staged yield type mild steel damper and its construction method

A technology of mild steel damper and construction method, which is applied in the direction of building type, building, and building material processing, and can solve the problems that the staged yield cannot be better realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

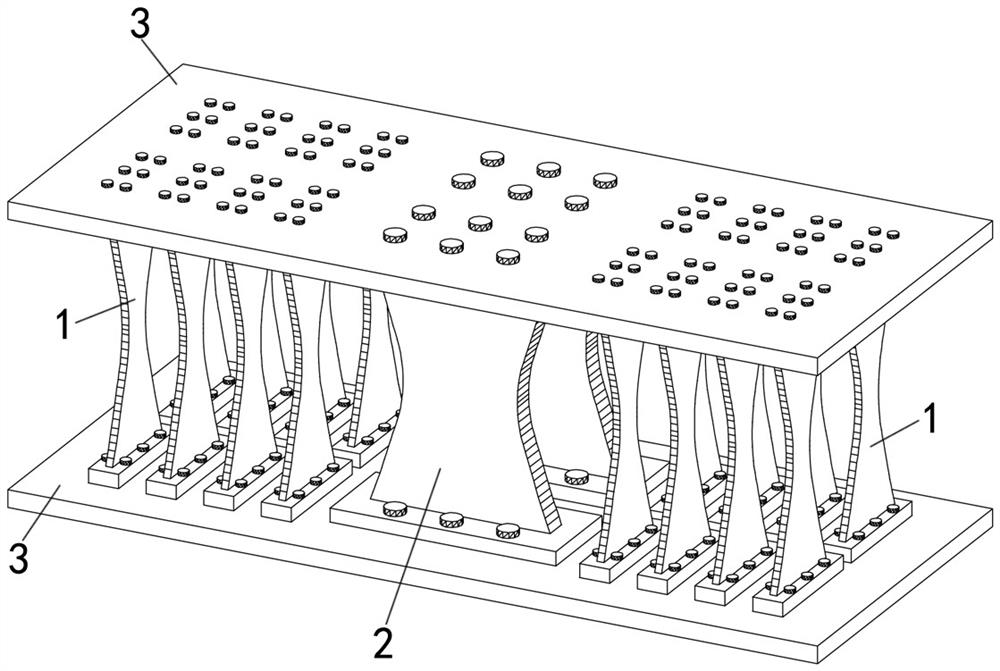

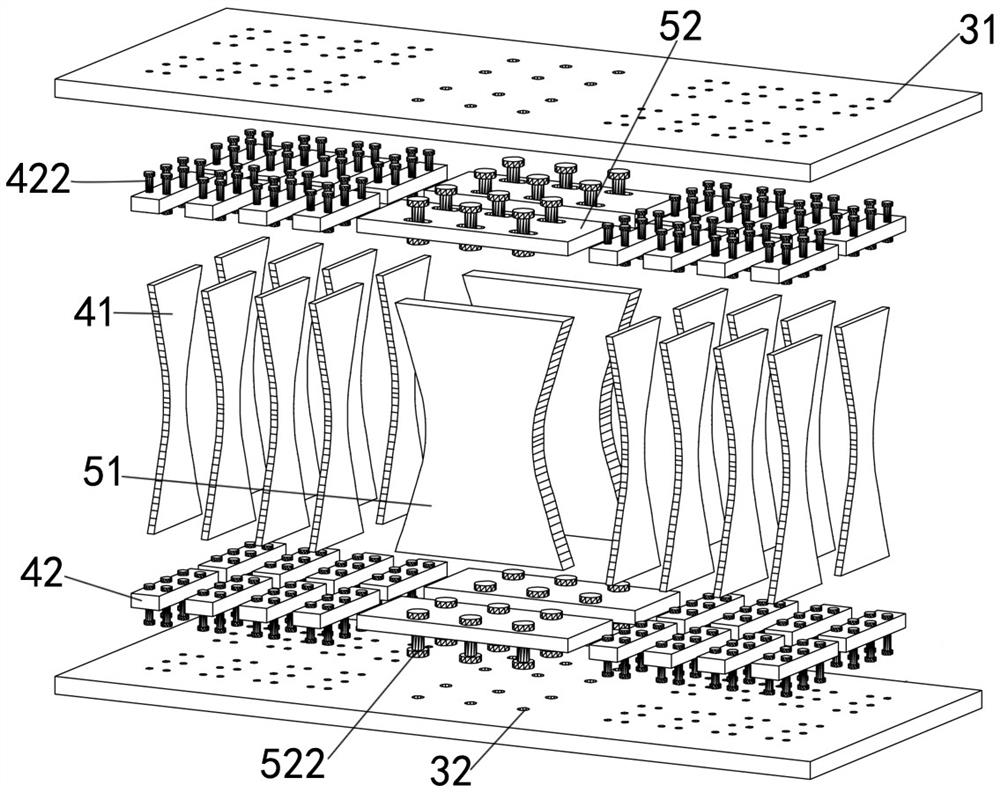

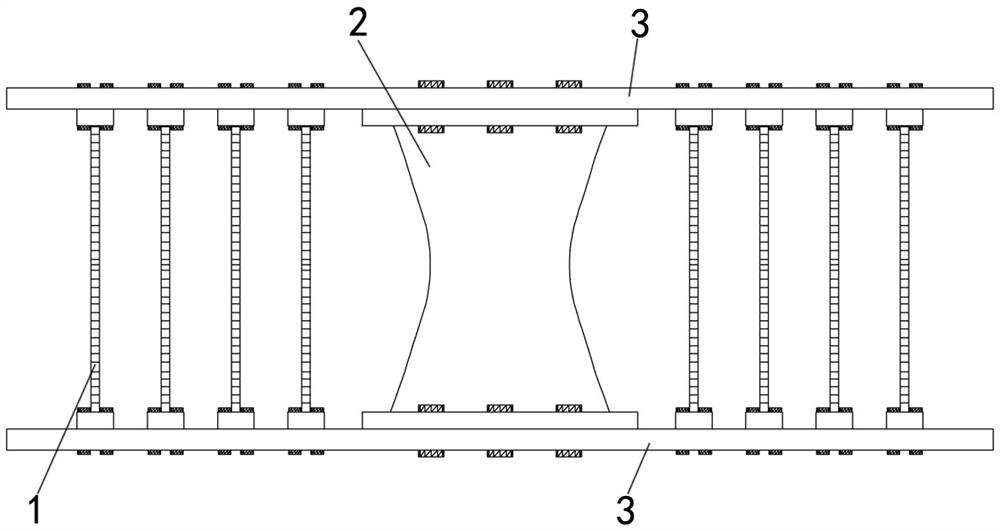

[0053] see example Figure 1-4 As shown, a staged yielding mild steel damper includes a body, the body includes a horizontal connection base 3 and a vertical energy dissipation member, the connection base includes two bases facing up and down, the consumption The energy piece is located between the two bases and its upper and lower ends are respectively fixedly connected to the two bases.

[0054] The energy dissipation member includes a first yielding member 1 and a second yielding member 2 that are perpendicular to each other. The first yielding member is divided into two parts, which are located on both longitudinal sides of the main body and are symmetrically arranged, and each part includes a longitudinal direction of the main body. A group of first yielding unit groups arranged in a row, the first yielding unit group is provided with one longitudinal row or more than two horizontally parallel rows, each row of the first yielding unit group includes a set of first yieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com