Cross-shaped sandwich thermal-insulating composite wall provided with energy-dissipation and damping keys and manufacturing method

A thermal insulation composite, cross-shaped technology, applied in the direction of thermal insulation, walls, shockproof, etc., can solve the problems of low seismic energy consumption, poor thermal insulation performance, slow construction speed, etc., to achieve high production efficiency, improve thermal insulation effect, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific implementation cases.

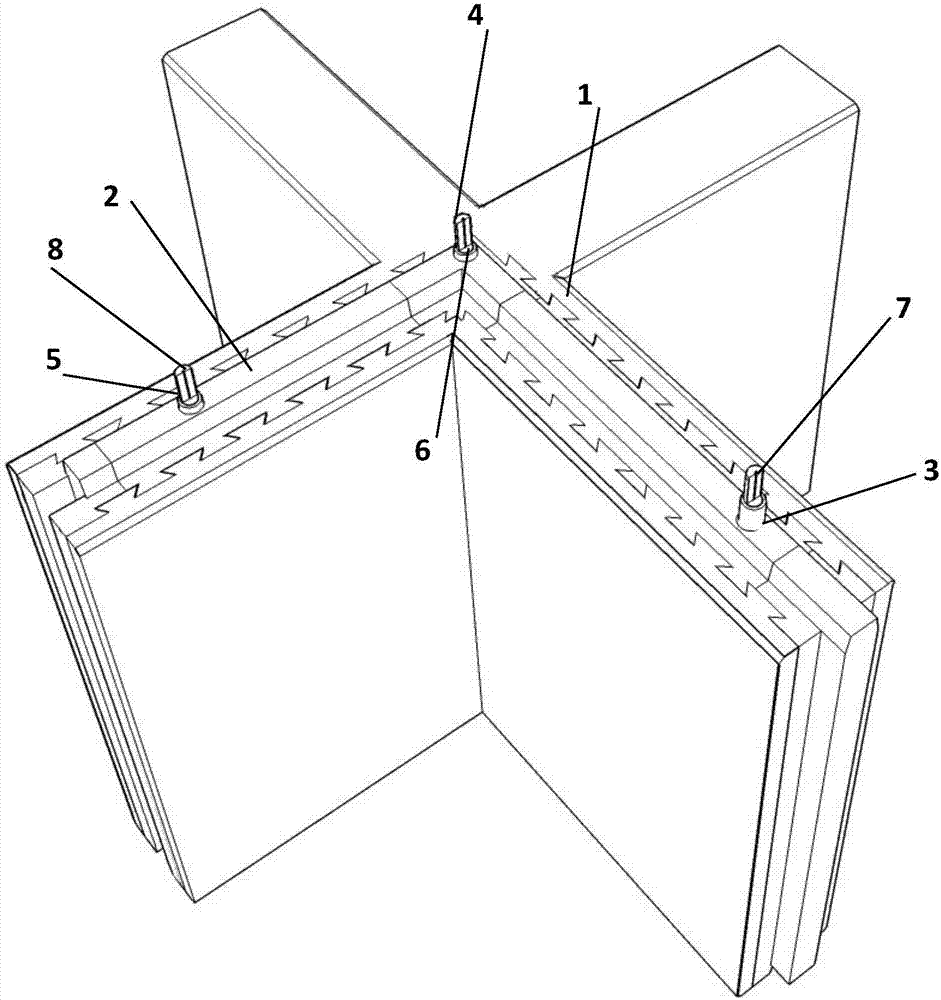

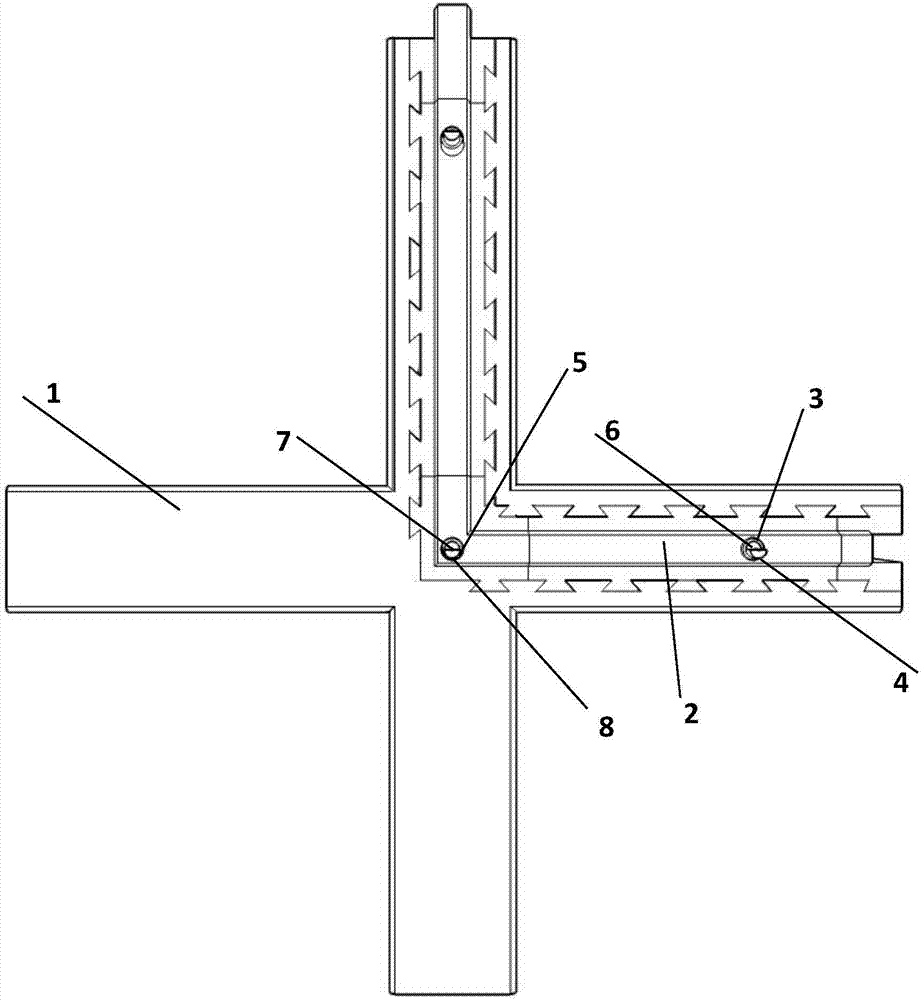

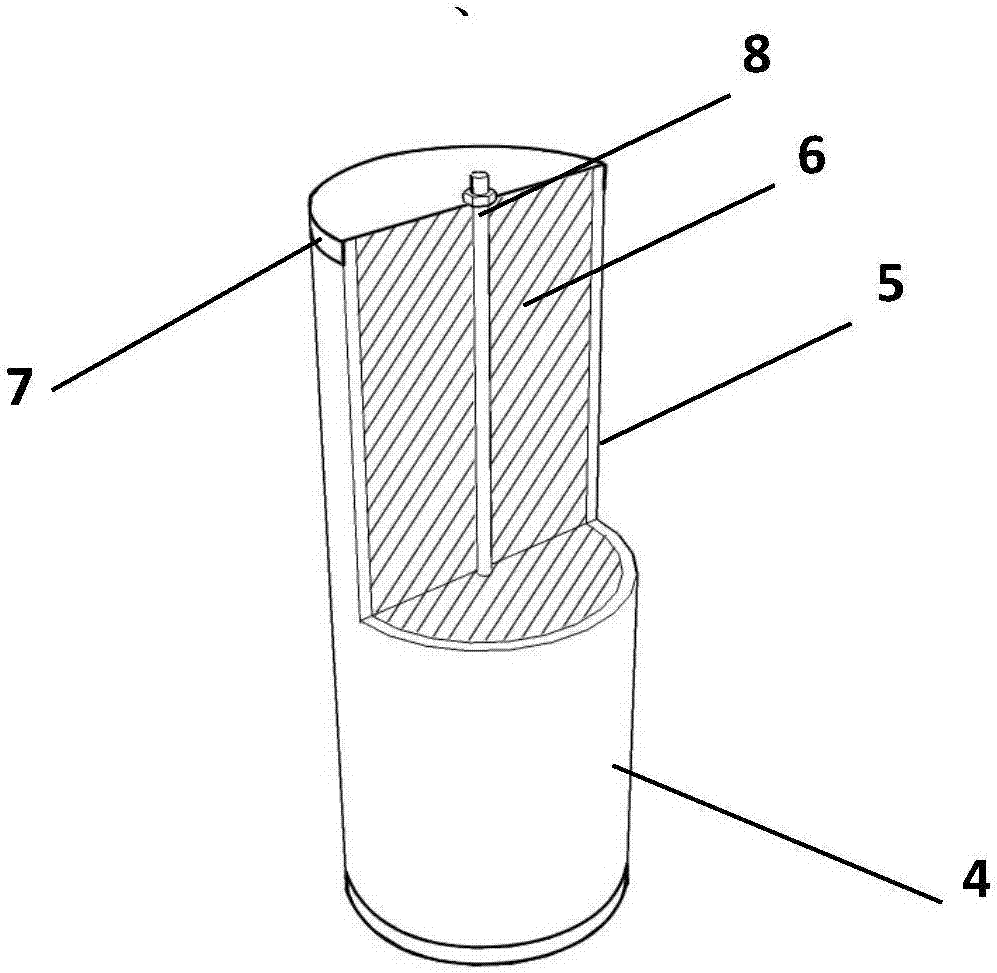

[0043] Such as figure 1 As shown, the cross-shaped sandwich thermal insulation composite wall with energy dissipation and shock absorption keys of the present invention includes a cross-shaped sandwich thermal insulation composite wall with recycled concrete wall panels 1, EPS thermal insulation modules 2, and wing circles on both sides of the composite wall. Pipe fixing parts 3, lead pipe-coarse sand energy dissipation key 4, lead pipe 5, coarse sand 6, galvanized thin steel sheet cover 7, bolt 8.

[0044] in particular:

[0045] The recycled concrete wallboard 1 is composed of recycled concrete and a single-row reinforced steel wire mesh, wherein the diameter of recycled concrete coarse aggregate particles is 5mm-10mm; the specifications of recycled concrete wallboard 1: the length is 600mm-6000mm, and the length modulus is 300mm; the section height is 300mm-1500mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com