Helicopter rotor shaft bearing pack testing machine

A technology of testing machine and bearing group, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of inaccurate test results, impossibility of testing due to the influence of the use of rotor shaft bearings, reduction of grease, etc., and achieve the comprehensive effect of the testing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

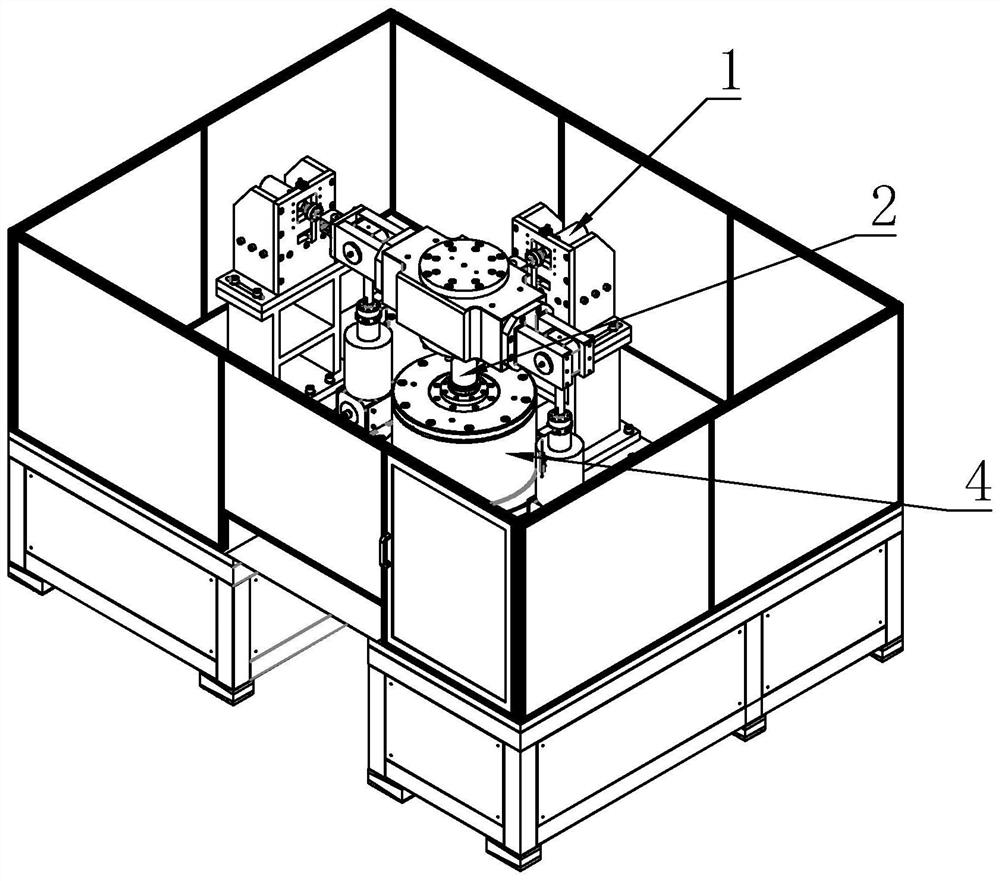

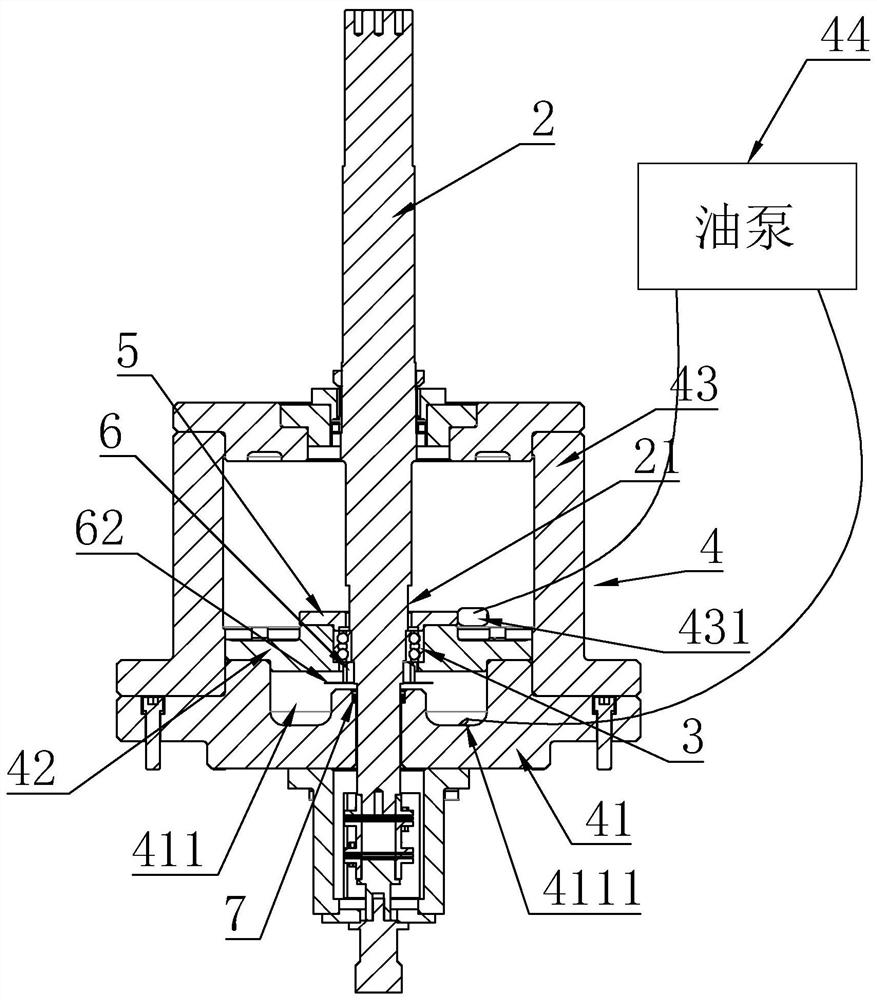

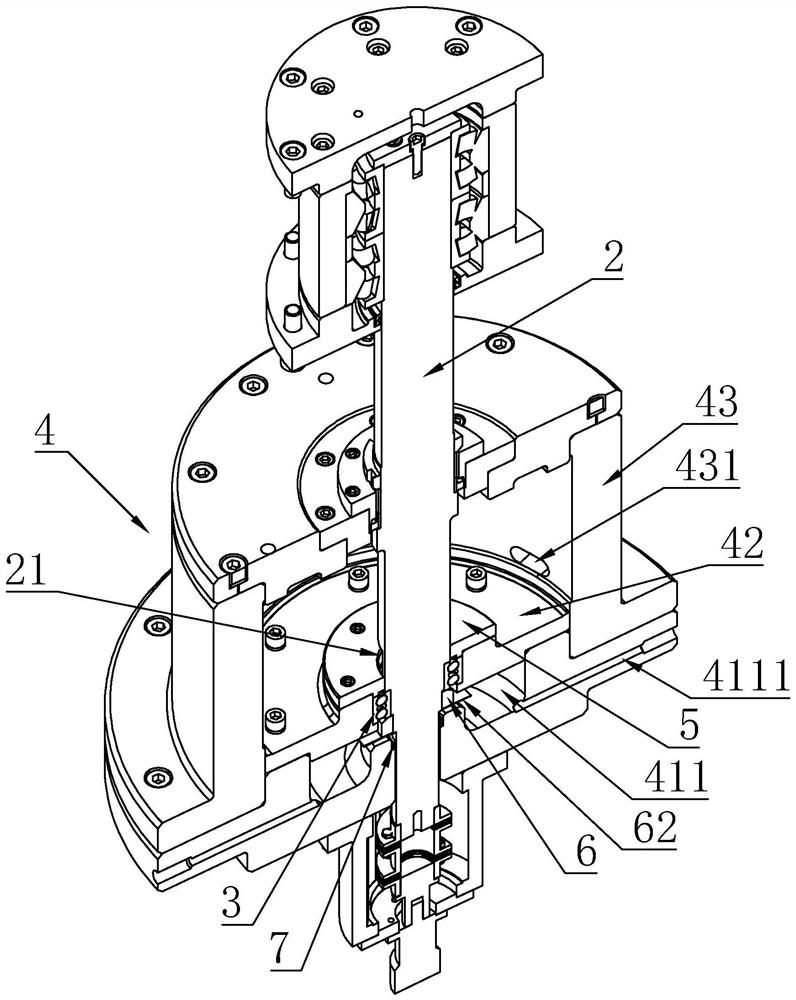

[0025] Helicopter rotor shaft bearing group testing machine, including loading part 1, test mandrel 2, test bearing 3 sleeved on test mandrel 2, assembly assembly 4 for installing test mandrel 2 and test bearing 3, assembly assembly 4 It includes a fixed base 41 for rotationally connecting the test mandrel 2, a bush 42 for assembling the test bearing 3, and a cover 43 assembled with the fixed base 41. The bush 42 is located inside the cover 43 and the outer edge of the bush 42 Offset against the inner wall of the cover body 43; the fixed base 41 has an oil storage tank 411 for receiving the lubricating grease dropped by the test bearing 3, and an oil outlet 4111 communicating with the outside is arranged in the oil storage tank 411; the inner ring of the test bearing 3 and the test The mandrel 2 is fixedly matched, and the outer ring is fixedly matched with the bushing 42; the cover body 43 is provided with an oil inlet hole 431, and when the oil inlet hole 431 is filled with g...

Embodiment 2

[0033] Based on the scheme of Example 1, another optimization is made: the side of the pressure plate 5 opposite to the outer ring of the test bearing 3 is provided with a protrusion 51. When the pressure plate 5 and the bushing 42 are assembled to fix the outer ring of the test bearing 3, the protrusion 51 is against the outer ring of the test bearing 3. The outer ring of the test bearing 3; when the protrusion 51 is against the outer ring of the test bearing 3, there is a gap between the pressure plate 5 and the side of the test bearing 3 for grease to flow through.

[0034] The design of the protrusion 51 can on the one hand fix the outer ring of the test bearing 3 in a targeted manner, and on the other hand allow a gap between the pressure plate 5 and the bearing, and use this gap to match the gap 21 on the test mandrel 2, An oil delivery channel can be formed so that the lubricating grease can flow into the test bearing 3 more conveniently.

[0035] In order to further im...

Embodiment 3

[0039] A further optimization is made for the oil baffle 62 of Embodiment 2: the radial length of the oil baffle 62 extends to the position of the oil storage groove 411 . The radial extent of the oil baffle plate 62 can directly reach the position of the oil storage tank 411, and this setting avoids the problem of poor throwing effect at low speeds.

[0040] In a further configuration, a sealing ring 7 is also provided between the test mandrel 2 and the fixed base 41 , and the sealing ring 7 is located within the coverage of the oil baffle 62 . Utilizing the sealing ring 7 can provide an extra line of defense to ensure the sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com