Automatic stock ground stacking device and using method thereof

An automatic and stacking technology, which is applied in the field of automatic stacking devices in stockyards, can solve problems such as low operating efficiency, low degree of automation, and inability to automatically divide materials, and achieve compact structure, strong practicability, and improved operating quality and use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

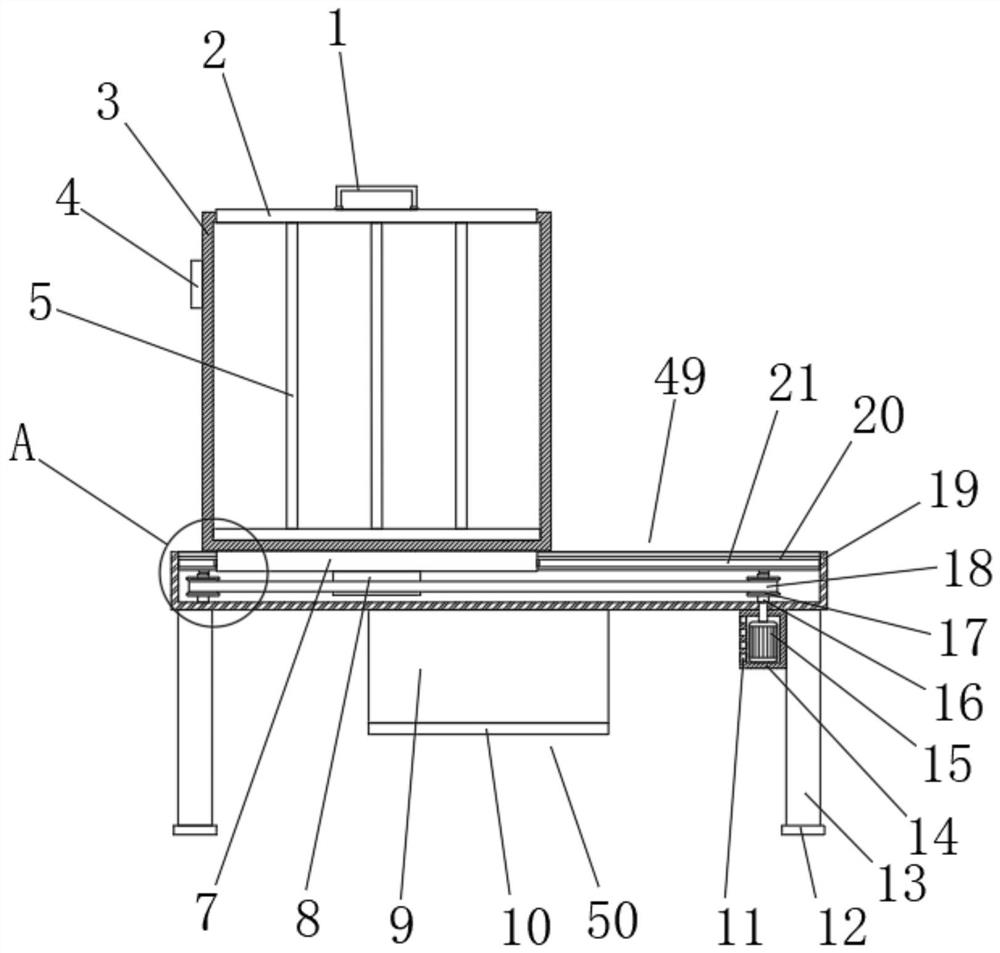

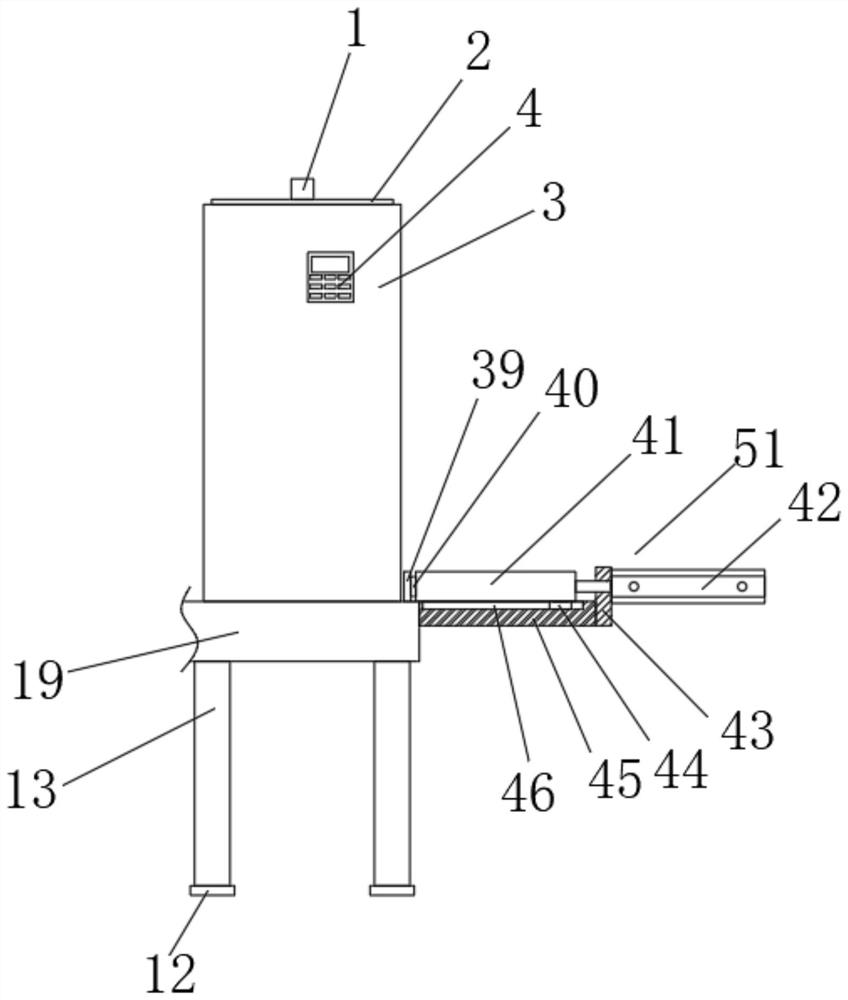

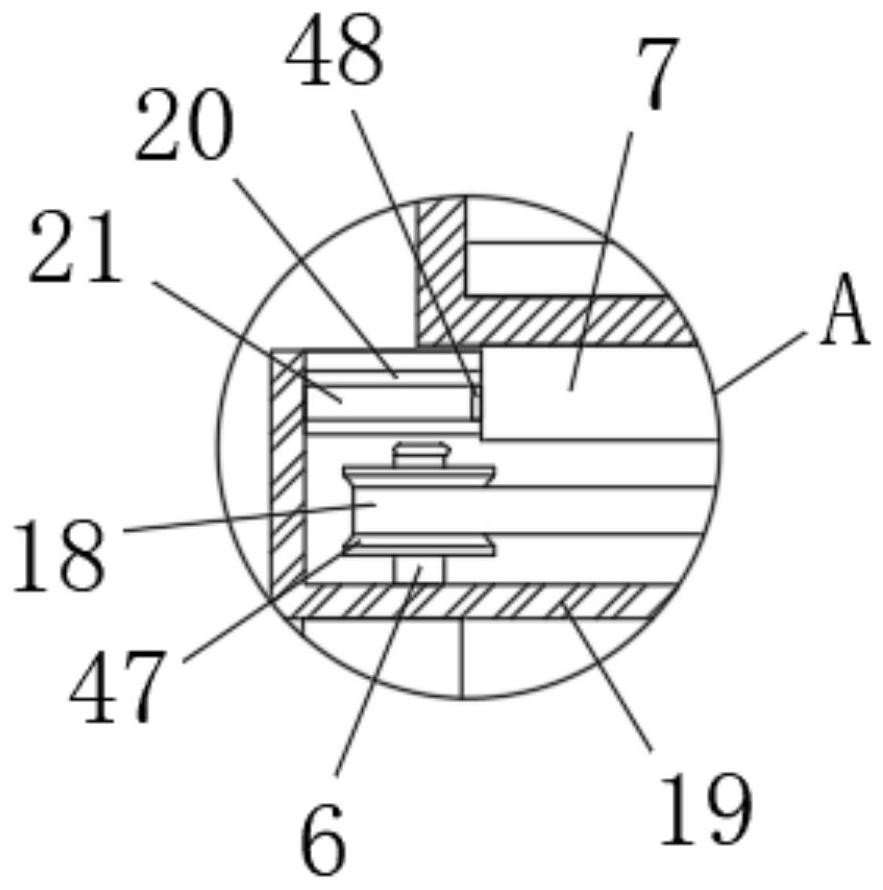

[0029] An automatic stacking device for a stockyard, comprising an installation box 19, a limit assembly 49 is provided inside the installation box 19, a blanking assembly 50 is provided on the outside of the installation box 19, and a blanking assembly 50 is provided on the side of the installation box 19 away from the blanking assembly 50. Discharging assembly 51, one side of mounting box 19 inner wall is fixedly installed with fixed strip 20, and the outside of fixed strip 20 is provided with first stop groove 21, and the inside of first stop groove 21 is slidably connected with slide block 48, slide block The outside of 48 is fixedly installed with the first mounting block 7, the top of the first mounting block 7 is fixedly mounted with the installation box 3, the outside of the installation box 3 is fixedly installed with the control panel 4, and both sides of the installation box 3 are provided with installation grooves 38 , equidistant between the inwall of installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com