Polystyrene square box core mold construction method for hollow floor system

A polystyrene, hollow floor technology, applied in the direction of floor slab, building material processing, building components, etc., can solve the problems of thin upper concrete layer or rib beam, affecting the quality of concrete pouring, quality accidents, etc. Heat dissipation, convenient installation and disassembly, and effective control of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by specific examples.

[0031] Such as Figure 1~Figure 8 Shown, a kind of polystyrene square box mandrel construction method that is used for hollow floor, comprises:

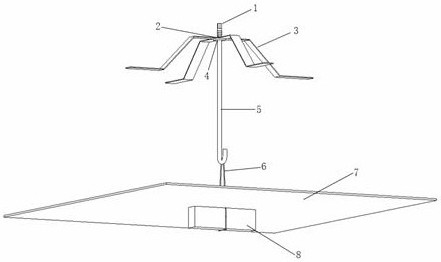

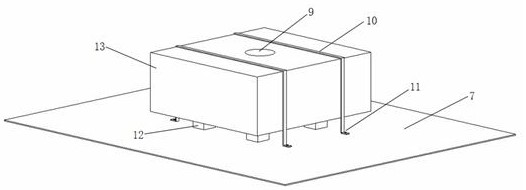

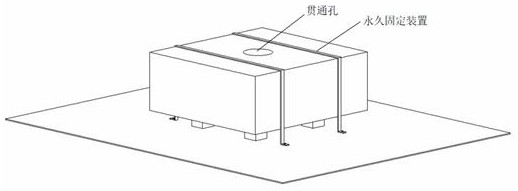

[0032] 1. Determine the size of each component of the special anti-floating device according to the actual size of the polystyrene mandrel in the drawing and the distance between the upper steel bars, and process several sets. The special auxiliary anti-floating device includes: outer screw nut 1, inner screw nut 2, fixed piece 3, gasket 4, screw column 5, iron wire or steel wire 6, template 7, square wood 8; figure 1 . The screw column is set in the middle of the hollow floor foam box; the upper end of the screw column is provided with a fixed gasket, thread and nut for fixing the fixing piece and the column; the lower end of the screw column is provided with a 180-degree hook, and the iron wire Pass through the formwork and connect with the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com