A construction method for sealing water at the bottom of a station and a structure for sealing water at the bottom of the station

A construction method and station technology, which are applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of occupying surface space, high cost, poor water-stopping effect, etc., and achieve power saving, simple construction method and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

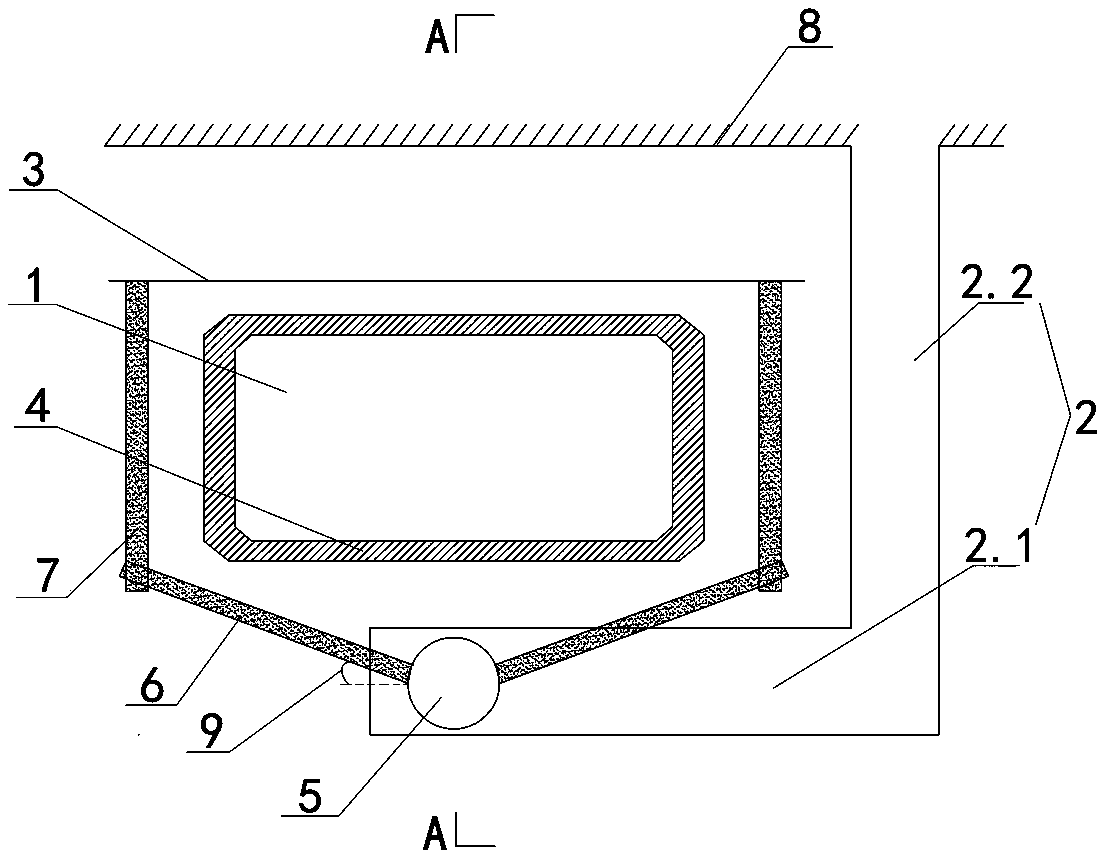

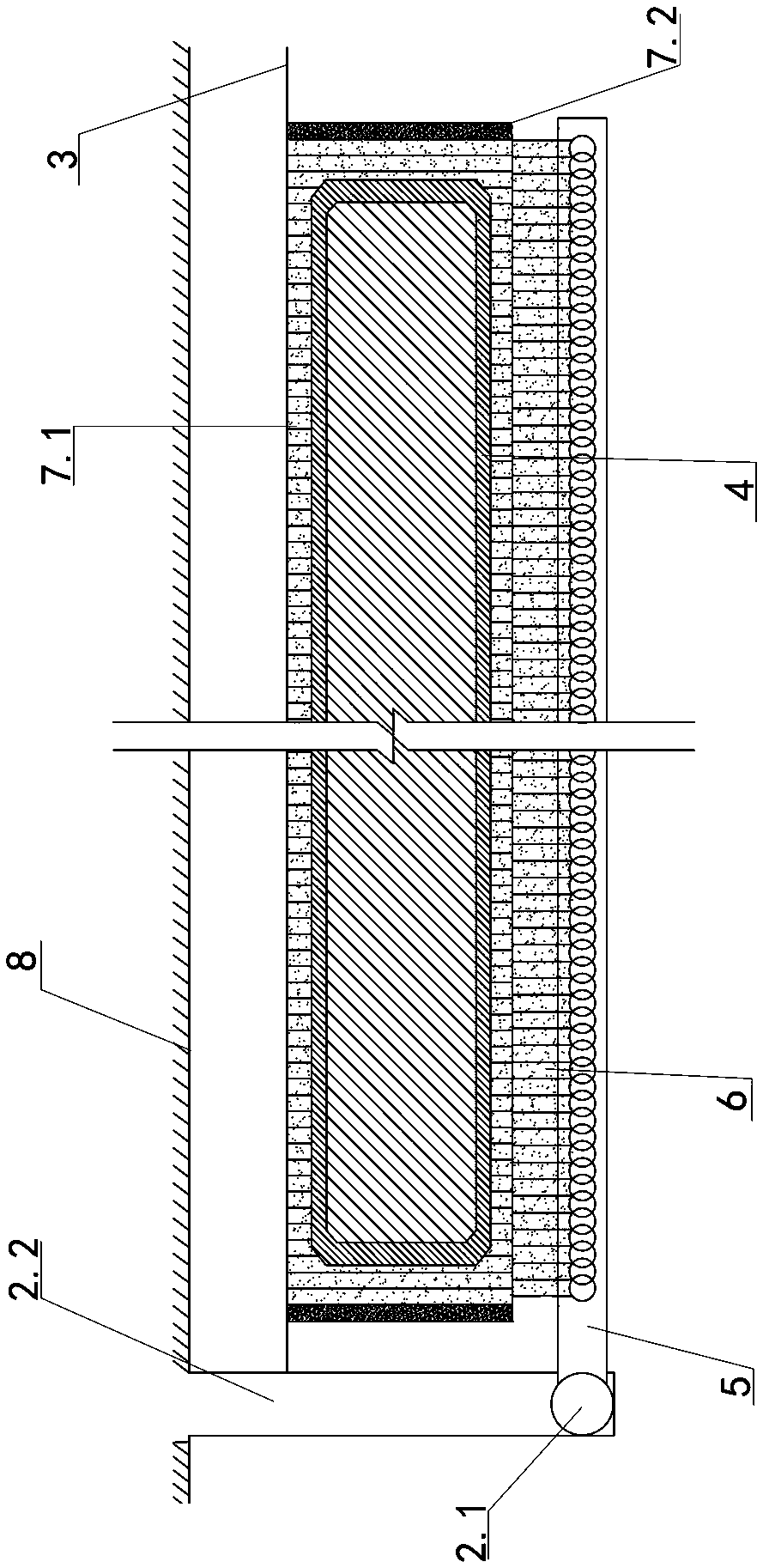

[0029] Examples see Figure 1-3 As shown, a subway station tunnel, its water level line 3 is as figure 1 shown. The horizontal direction described in the embodiment is the cross-sectional direction of the underground station tunnel to be built, and the longitudinal direction is the traveling direction of the underground station tunnel to be built.

[0030] The construction steps of this water sealing construction method at the bottom of the station are as follows:

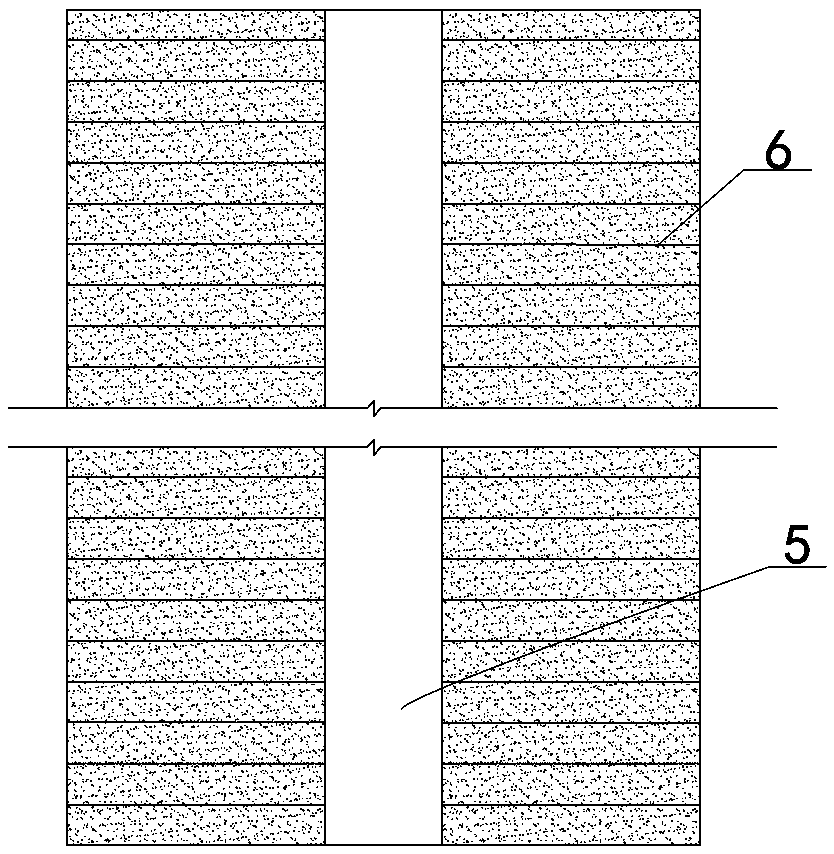

[0031] Step 1: Design the excavation route and depth of the underground tunnel 2, the excavation route and depth of the working face channel 5, and the lateral The two-wing water-stop curtain 6, wherein the elevation angle 9 formed by the horizontal two-wing water-stop curtain 6 and the horizontal plane is calculated and determined according to the anti-floating design requirements. The purpose is to form an inverted triangle curtain structure at the bottom of the station to increase the anti-floating effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com