Pipe clamp

A technology of clamps and closing elements, which is applied in the directions of pipe supports, pipe/pipe joints/pipes, sleeve/socket connections, etc., can solve the problems of non-existence, reduce the risk of failure, high load capacity, reduce The effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

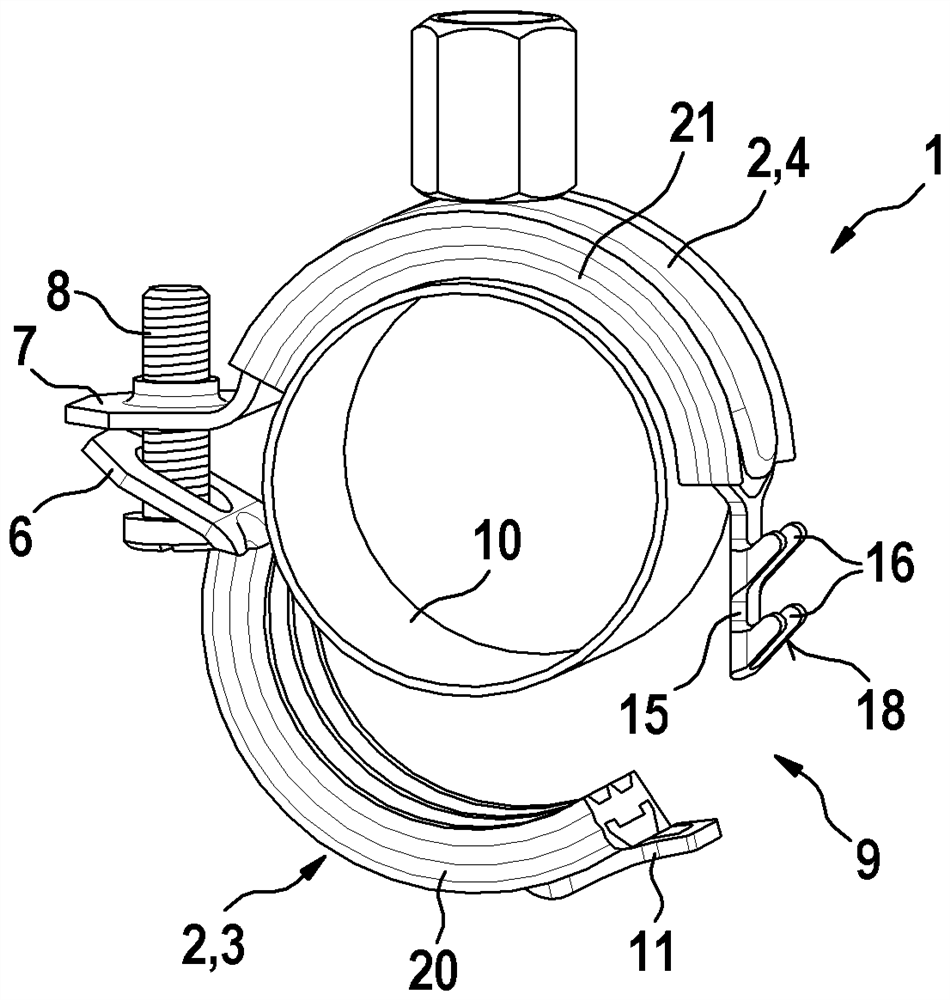

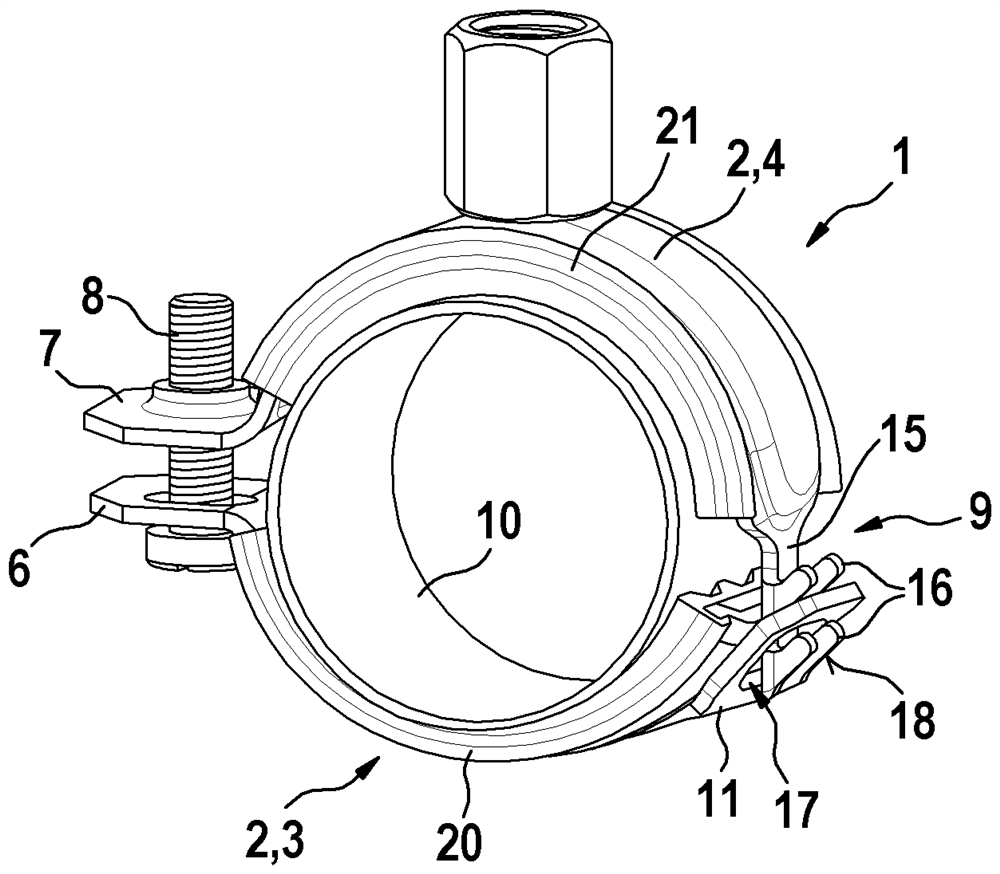

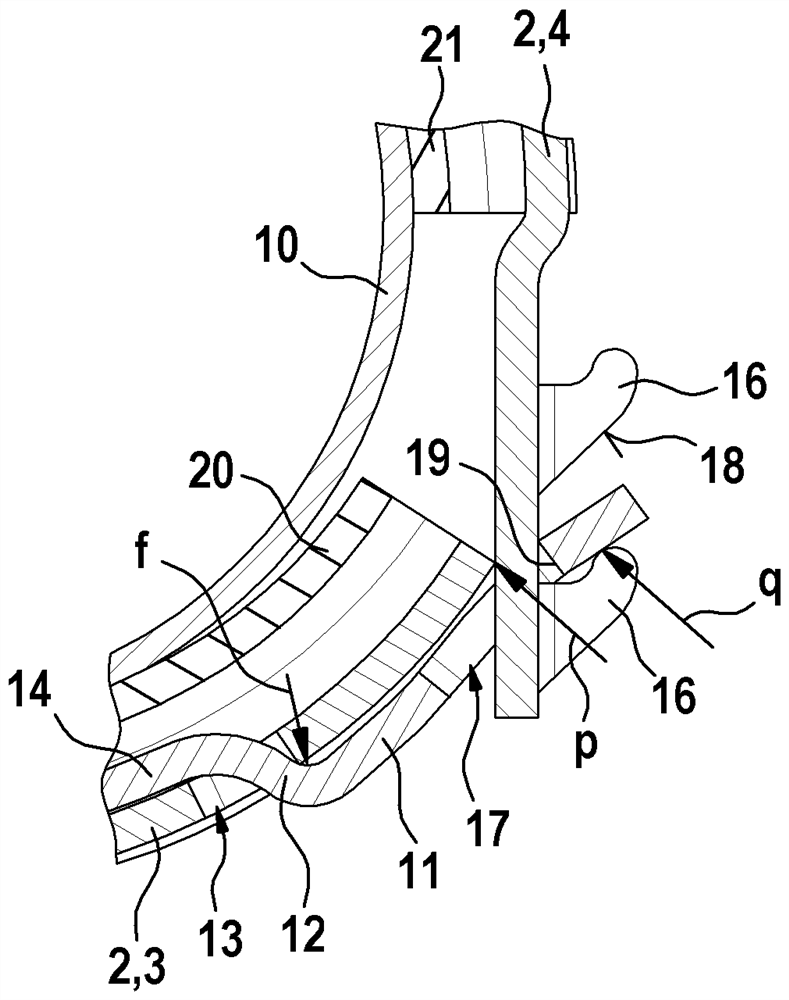

[0023] The pipe clamp 1 according to the invention shown in the drawing has a clamp body 2 with two circular arc-shaped clamp bows 3 , 4 which are bent from strips, but can also composed of other materials.

[0024] The second clamp bow 4 of the two clamp bows has a fastening nut 5 welded on the outside or otherwise arranged for fastening the pipe clamp 1 to a wall or ceiling, for example. The pipe clamp 1 can have no clamping nut 5 but, for example, a screw (not shown) protruding from one of the two clamp bows 3 , 4 .

[0025] At a second circumferential position, the two clamp bows 3 , 4 have flanges 6 , 7 protruding radially or precisely parallel to the axial plane, the first of which 6 has a through hole through which a tensioning screw 8 passes, and the second one of the flanges 7 has an internally threaded hole into which the tensioning screw 8 is screwed. The two clamp bows 3, 4 are thus hingedly connected, and as figure 2 shown, can be pivoted separately from each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com