Patents

Literature

31results about How to "Viscosity has little effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

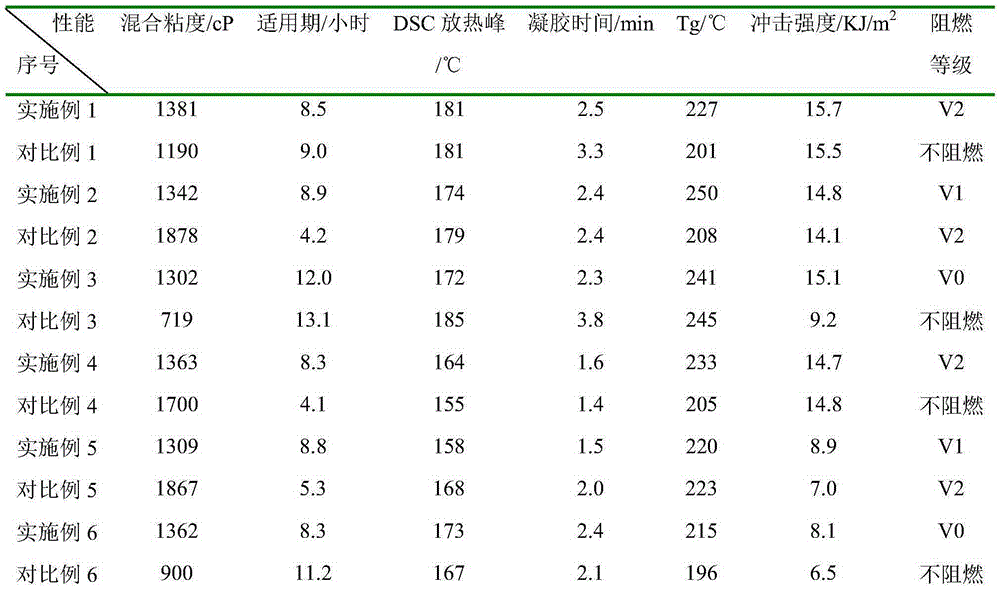

Flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and preparation method thereof

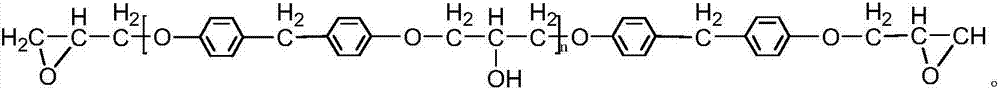

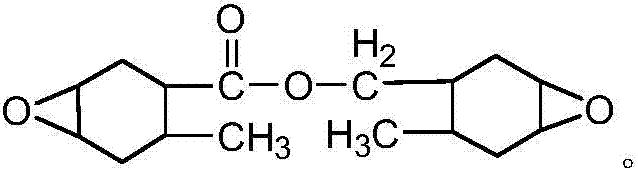

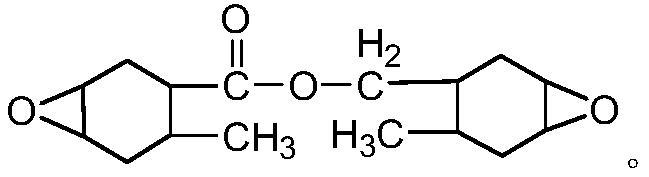

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

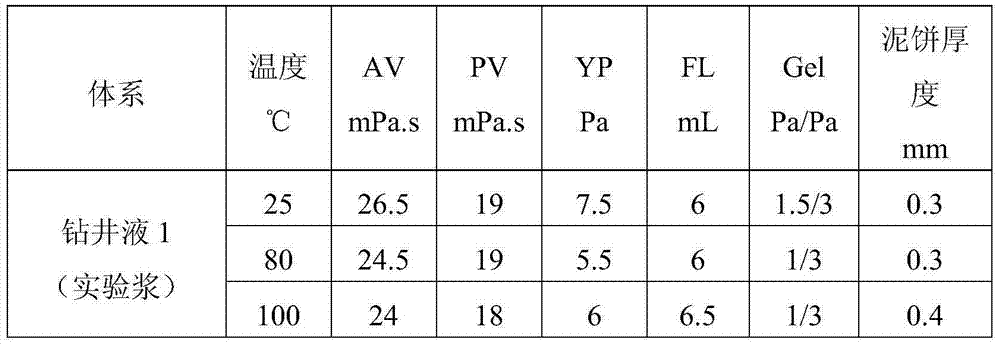

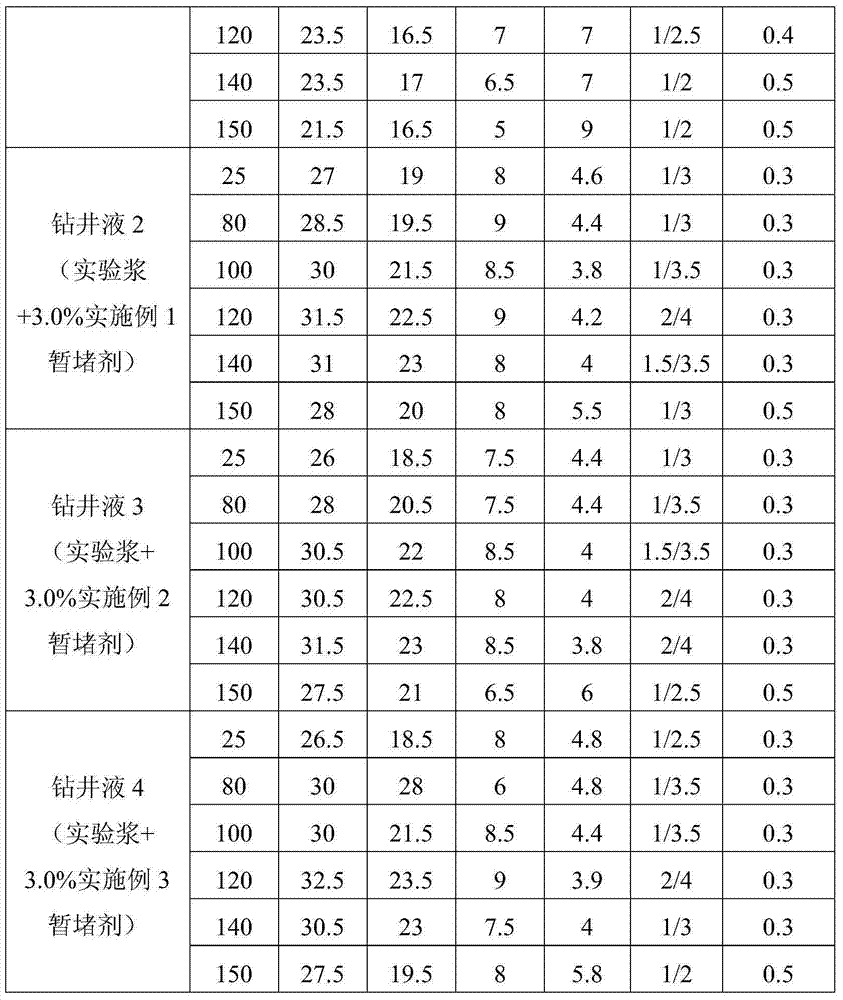

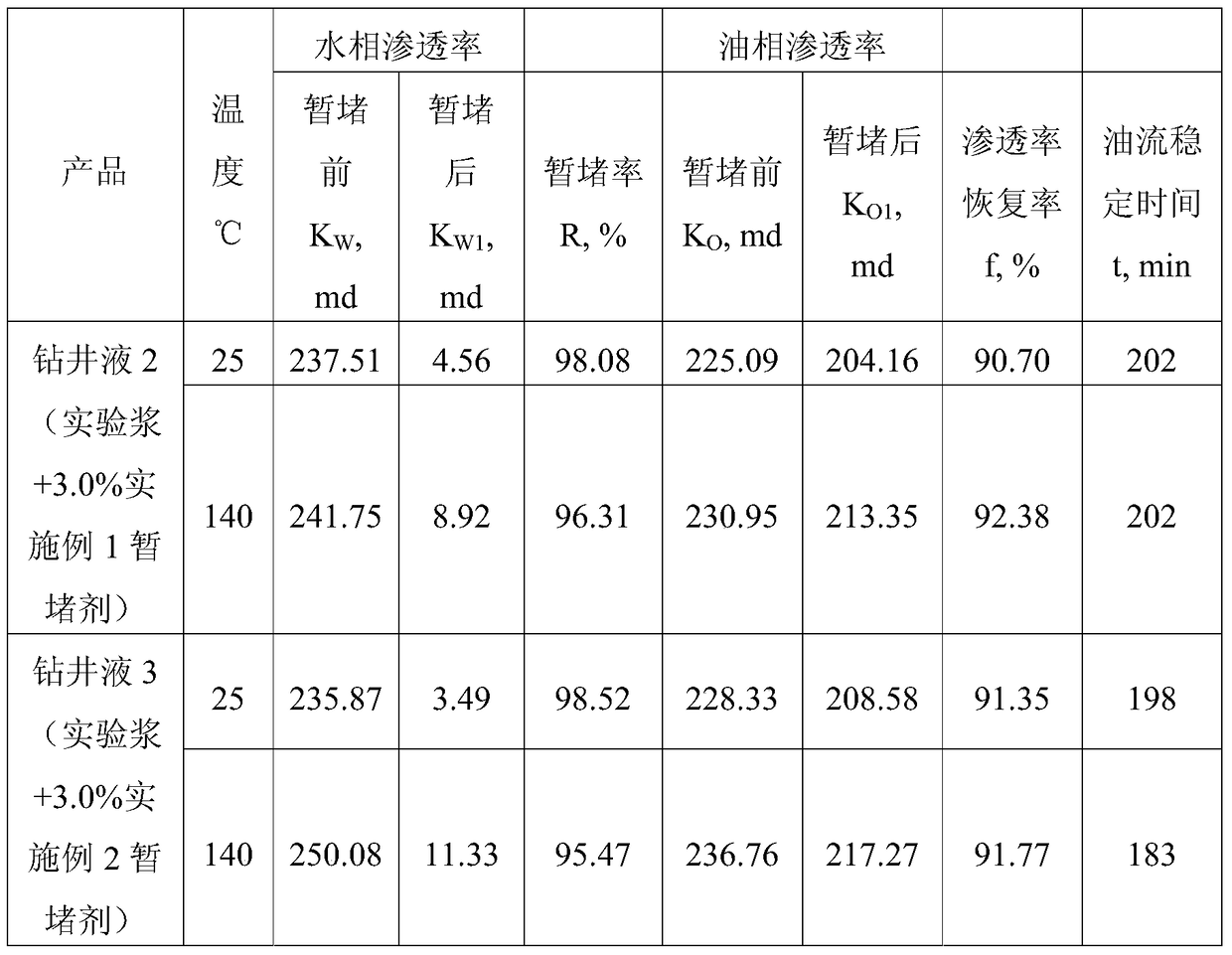

Self-plugging releasing temperature resistant temporary plugging agent used for water-based drilling fluid and preparation method thereof

ActiveCN104710967AHigh temperature resistanceSignificant temporary blocking effectDrilling compositionWater basedAcid washing

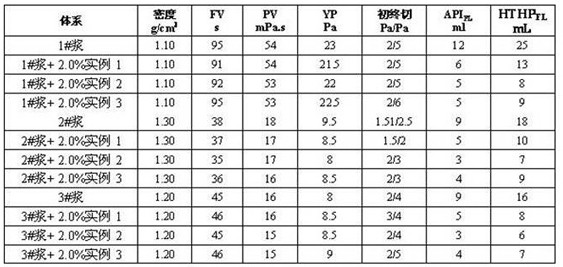

The invention provides a self-plugging releasing temperature resistant temporary plugging agent used for water-based drilling fluid, the self-plugging releasing temperature resistant temporary plugging agent comprises nano calcium carbonate and a product which is obtained by reacting starch, alkali metal hydroxide, halogenated organic acid, carbonate, a hydrophobic modification agent and alcohol with water. The invention also provides a preparation method of the self-plugging releasing temperature resistant temporary plugging agent used for the water-based drilling fluid, and the self-plugging releasing temperature resistant temporary plugging agent used for the water-based drilling fluid can be obtained by proportionally adding components into a kneading machine for kneading. The self-plugging releasing temperature resistant temporary plugging agent has strong high temperature resistance, and can resist the temperature up to 140 DEG C; and the self-plugging releasing temperature resistant temporary plugging agent has good temporary plugging effect and significant reservoir protection effect, and the water-based drilling fluid added with the temporary plugging agent has high temporary plugging rate and oil phase permeability recovery rate; at the same time, the temporary plugging agent has self-plugging releasing ability. During the late flowback, the self-plugging releasing can be realized by formation of a hydrophobic channel without acid washing for mud cake removal and other processes, and secondary damage to a reservoir can be avoided.

Owner:CHINA PETROCHEMICAL CORP +1

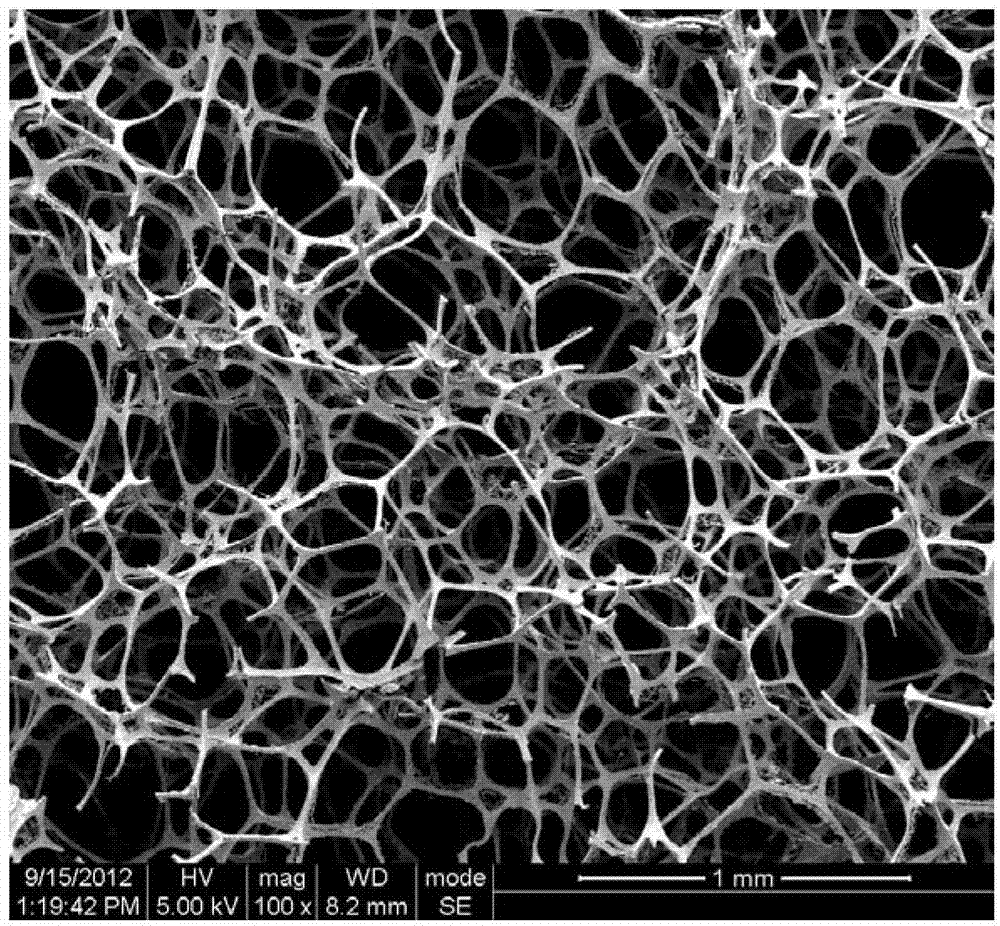

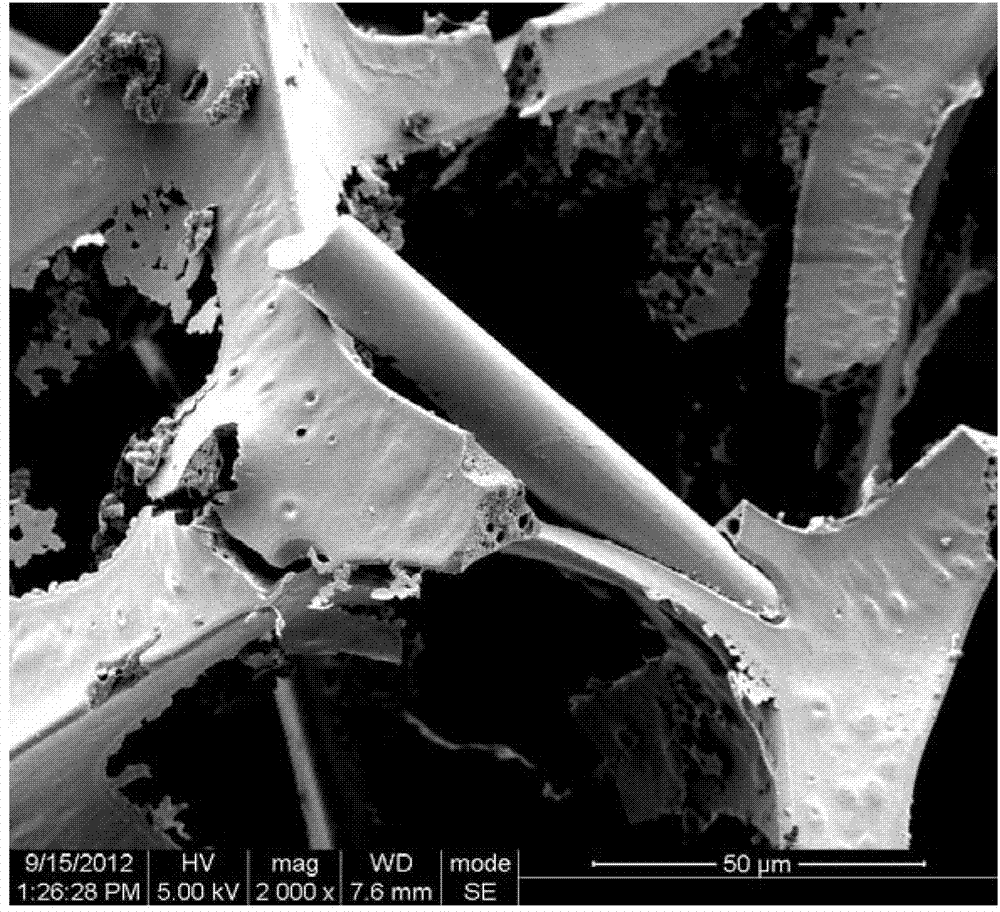

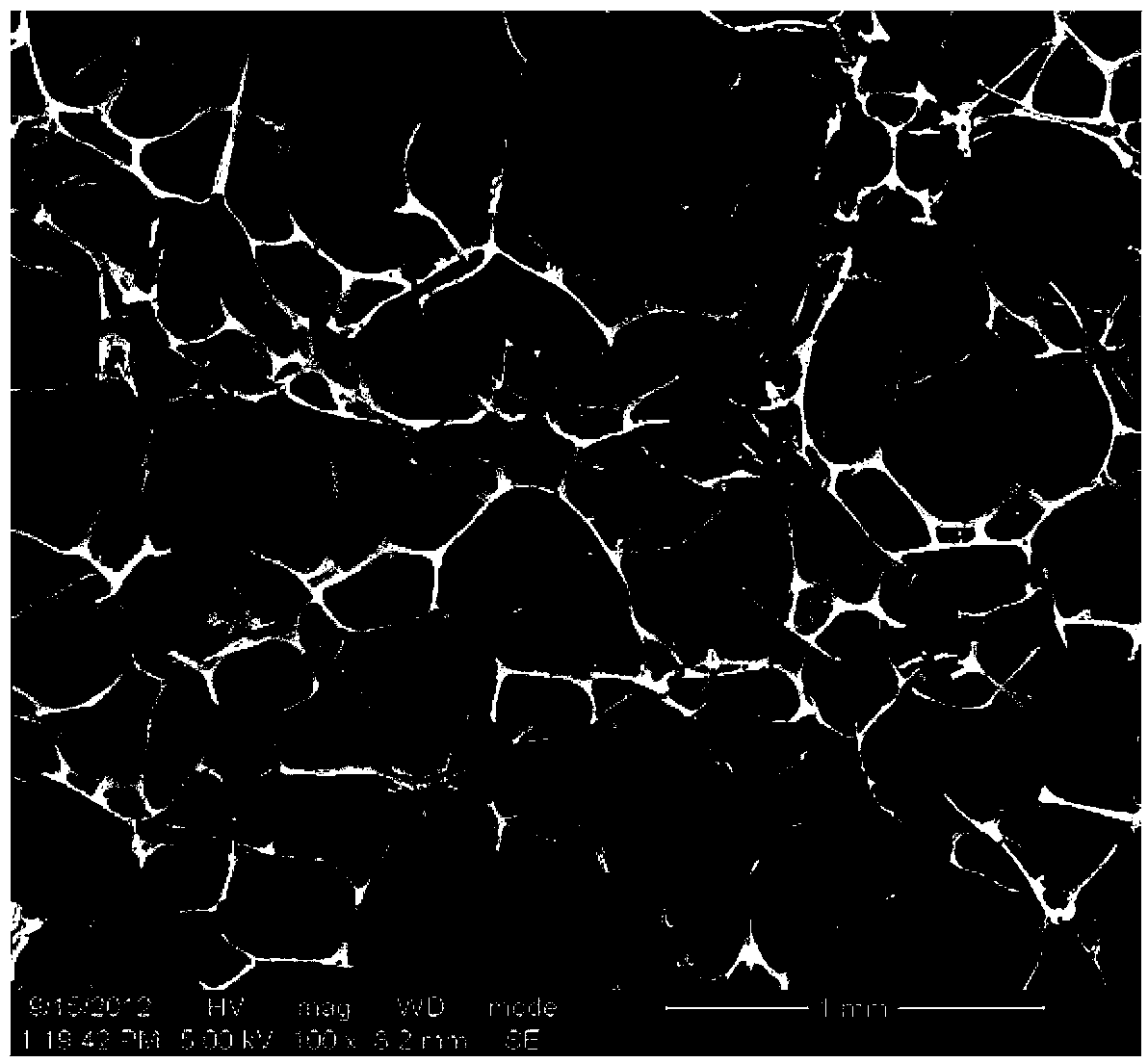

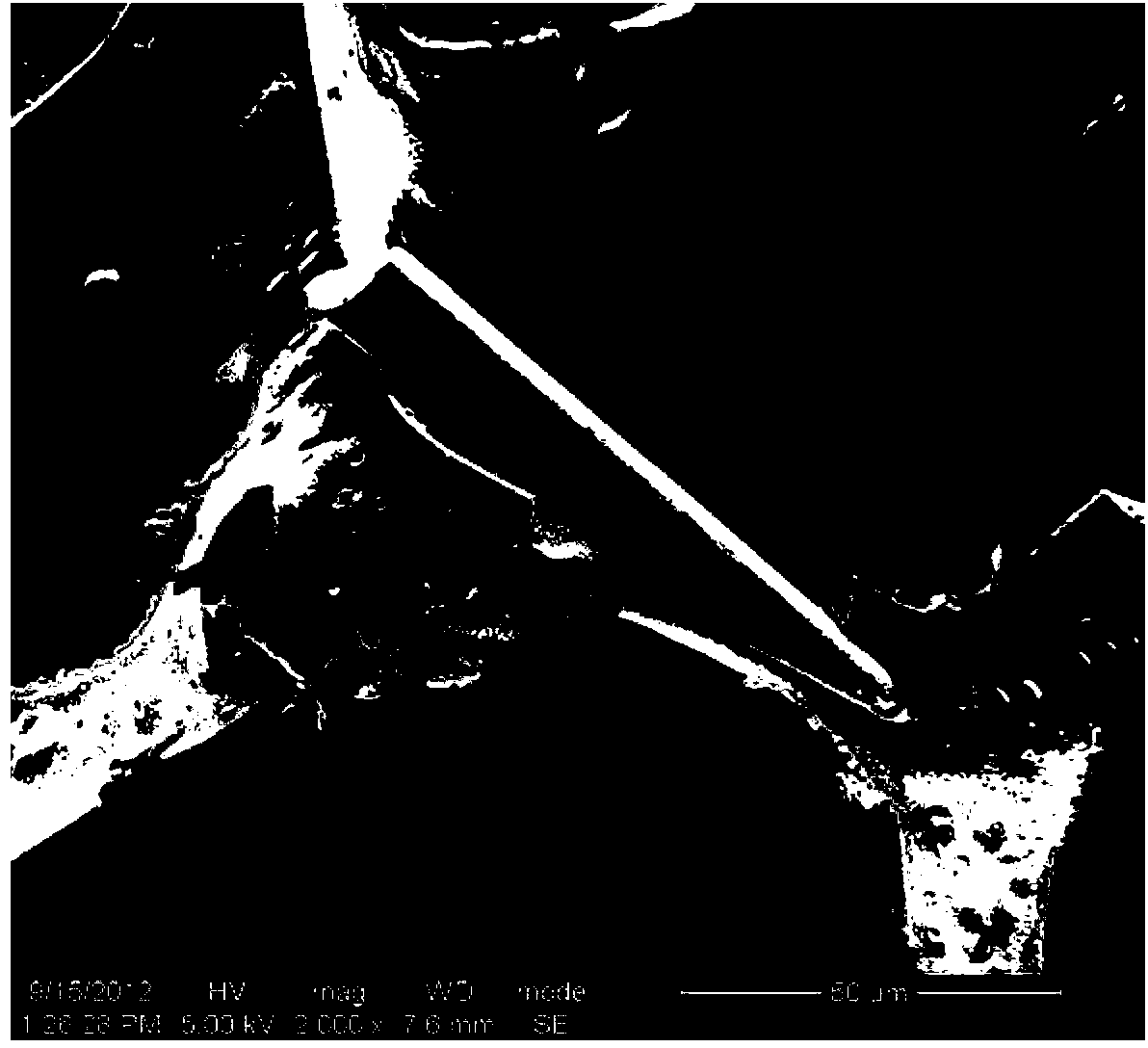

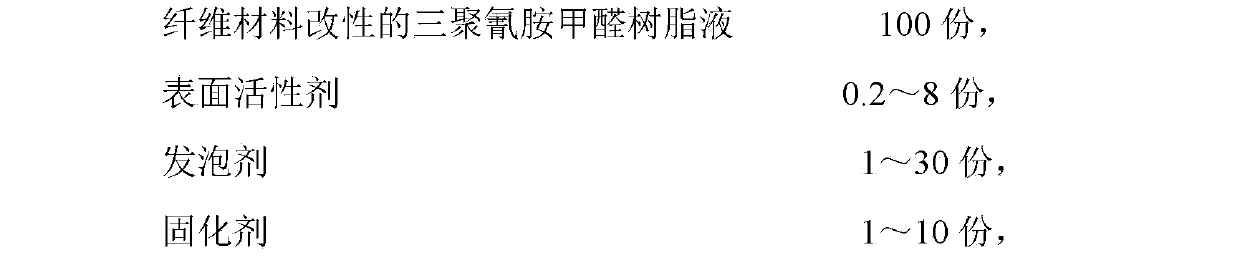

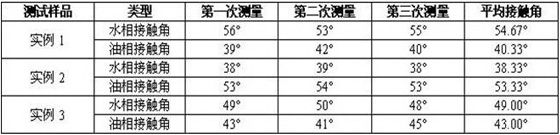

Fiber material modified melamine formaldehyde foam and preparation method thereof

ActiveCN103030924ASolve the problems of brittleness, powder falling, poor flexibility and low compressive strengthHigh compressive strengthFiberMelamine formaldehyde

The invention discloses fiber material modified melamine formaldehyde foam. The foam is formed by solution foaming of the following constituents in parts by weight: 100 parts of fiber material modified melamine formaldehyde resin solution, 0.2-8 parts of a surface active agent, 1-30 parts of a foaming agent and 1-10 parts of a curing agent, wherein the content of the fiber material is 0.2-10% of the sum of the mass of the formaldehyde solution and the melamine before polymerization of the resin solution. The invention further discloses a preparation method of the melamine formaldehyde foam. The melamine formaldehyde foam provided by the invention is excellent in fire resistance, and the mechanical properties, such as flexibility and compression strength, of the foam are also improved greatly; and moreover, the preparation method of the foam is simple and easy to carry out, and the production cost is low, large-scale popularization and application of the foam are facilitated.

Owner:SICHUAN UNIV

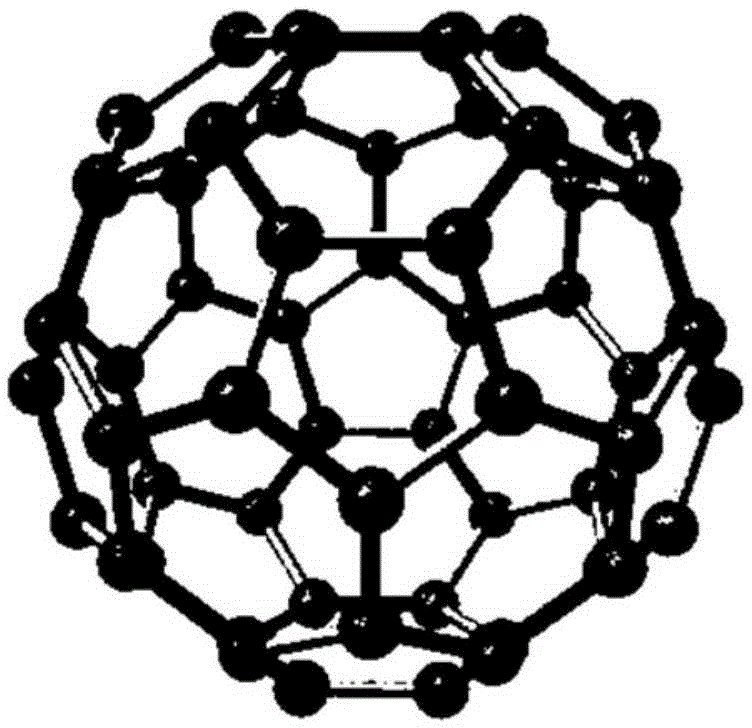

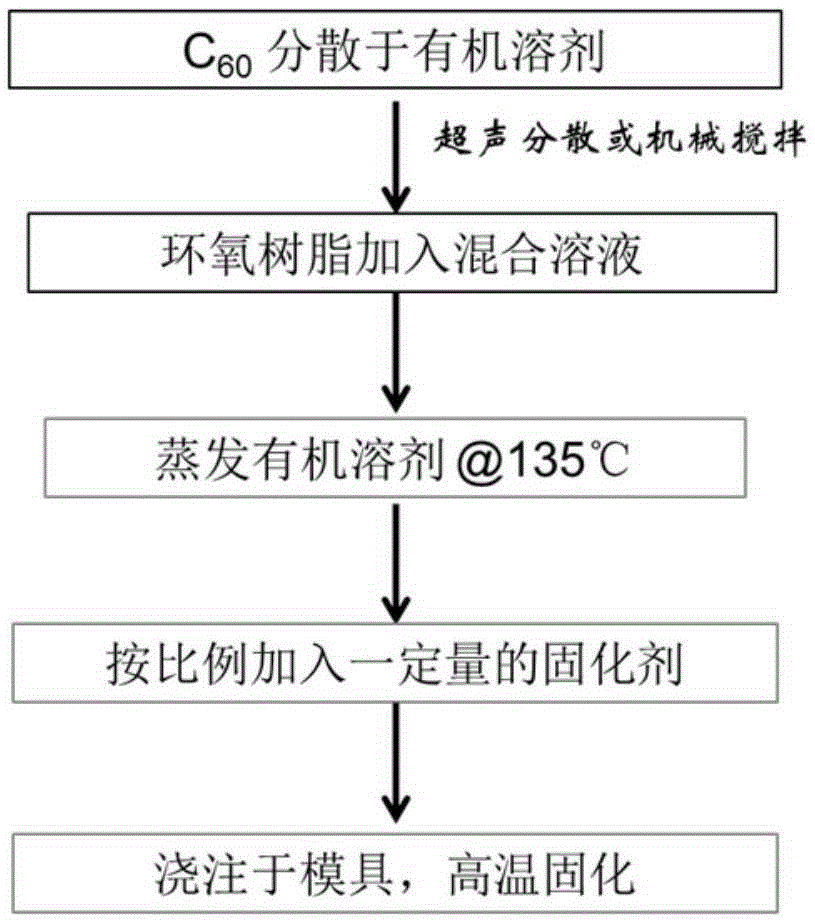

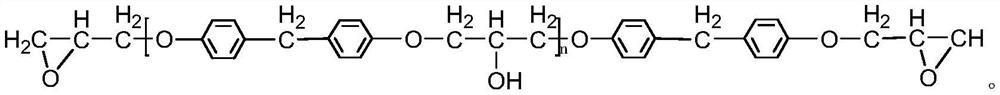

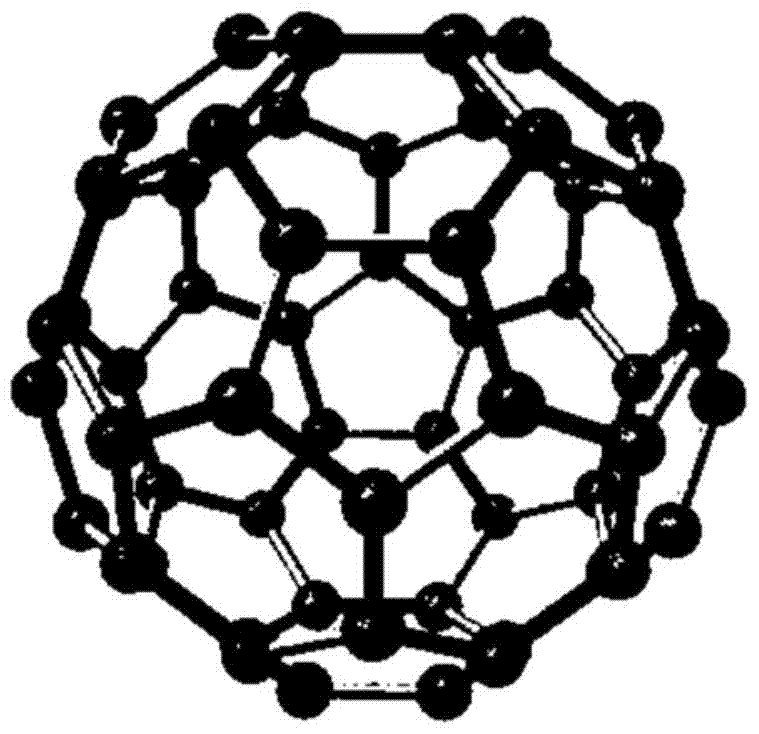

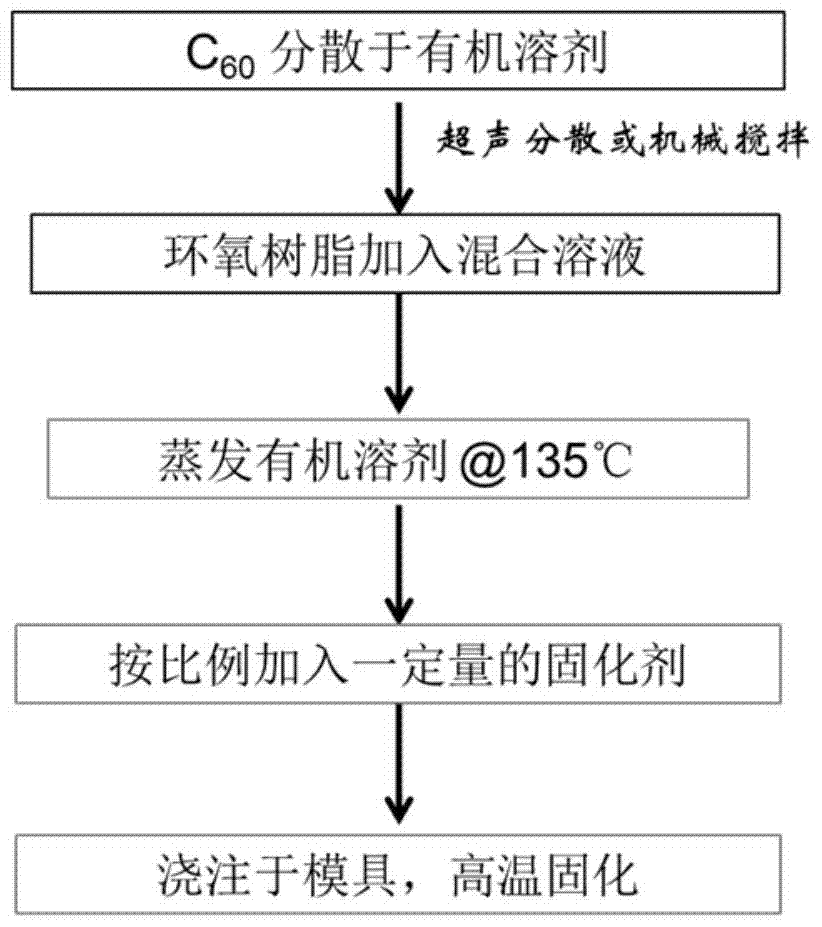

Epoxy resin fullerene composite material and preparation method thereof

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

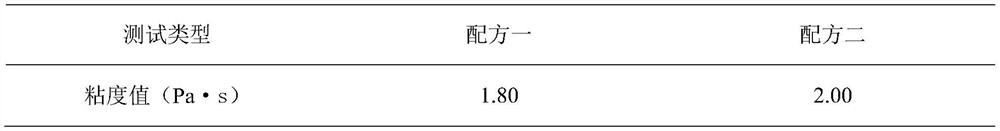

LED chip insulating heat-conducting solid crystal glue and preparation method thereof

ActiveCN107974232AViscosity has little effectImprove thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveFilling materials

The invention belongs to the technical field of adhesive, and in particular relates to LED chip insulating heat-conducting solid crystal glue and a preparation method thereof. The specially-made heat-conducting filling material is formed by mixing heat-conducting filling materials with different shapes such as a needle shape, a sheet shape or a spherical shape; the needle-shaped and spherical heat-conducing filling materials and a certain amount of connecting agent are premixed, so that the needle-shaped and spherical heat-conducing filling materials are mutually connected to form a certain three-dimensional structure; the certain three-dimensional structure as well as resin, a crosslinking agent, a catalyst, adhesive and the like are mixed, so that distance does not exist between the heat-conducting filling materials within a certain range, the heat-conducting coefficient is high, the use amount of the filling materials is small, influence on the viscosity of colloid is low, the adhesion performance is excellent, the heat-conducting coefficient can be obviously increased and the purpose of improving the conducting efficiency is fulfilled.

Owner:YANTAI DARBOND TECH

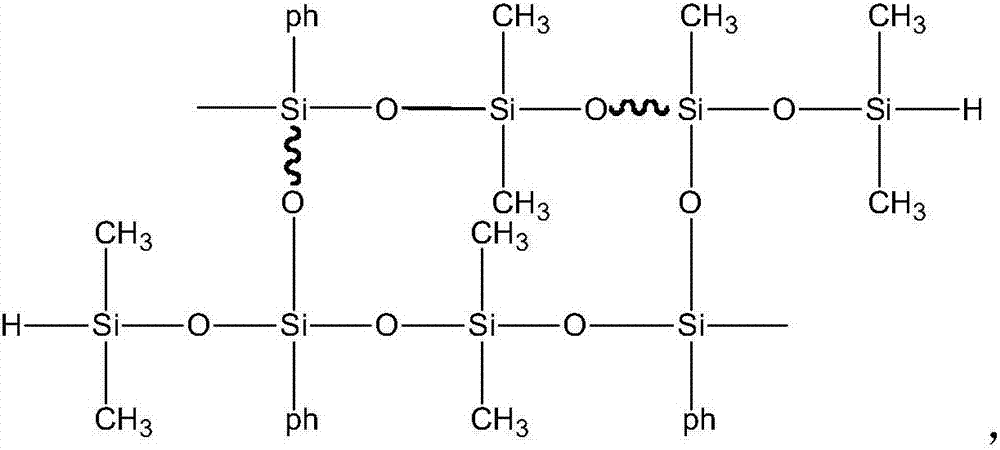

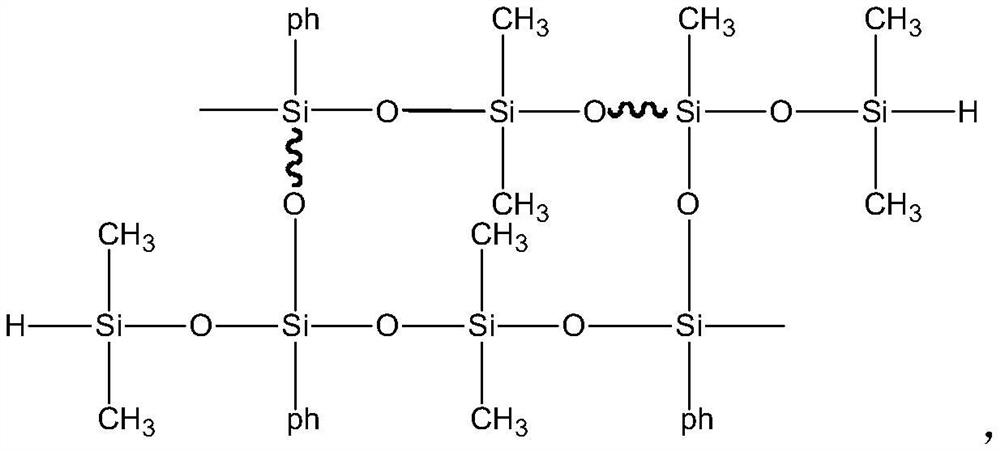

Preparation method of silicone resin for adhesion of solvent-free environment-friendly glass fiber

ActiveCN103484057AWill not polluteReduce consumptionNon-macromolecular adhesive additivesGlass fiberPlatinum complex

The invention provides a preparation method of silicone resin for adhesion of solvent-free environment-friendly glass fiber. The preparation method comprises the steps of (1) preparing solvent-free vinyl MDTQ silicone resin; (2) preparing vinyl phenyl silicone oil; (3) adding the vinyl MDTQ silicone resin, the vinyl phenyl silicone oil and precipitation method silicon dioxide into a reaction kettle according to the proportion of (2-4): (5-7): (1-2) in parts by weight, heating to 150-200 DEG C under stirring conditions, performing heat preservation for 2h, cooling and discharging to obtain base glue; (4) taking 100 parts by weight of the base glue, adding 8-6 parts by weight of hydrogen-containing silicone oil with the hydrogen content of 0.2-1%, uniformly stirring, and then packaging to obtain a component A; (5) taking 100 parts by weight of the base glue, adding 0.5-2 parts by weight of platinum complex catalyst, uniformly stirring, and then packaging to obtain a component B. When the A-B dual-component solvent-free silicone resin prepared by the preparation method provided by the invention is coated, organic solvents do not need to be added, the coating efficiency is improved, and the environmental pollution can be avoided.

Owner:襄阳玖润氟硅材料有限公司

High-temperature-resistant and salt-resistant filtrate loss reducer for drilling fluid and preparation method and application of filtrate loss reducer

InactiveCN106366244AImprove performanceViscosity has little effectDrilling compositionFiltrationWhite powder

The invention discloses a high-temperature-resistant and salt-resistant filtrate loss reducer for drilling fluid and a preparation method and application of the filtrate loss reducer. The preparation method comprises the following steps that 2-acrylamido-2-methylpropane sulfonic acid and water are added into a reactor and stirred to be fully dissolved; acrylic acid is added into the reactor, then a pH value regulator is added, and the pH value of the mixture in the reactor is regulated to be 7-9; N-isopropylacrylamide and nano-calcium bentonite are added into the reactor and stirred to be uniform; an initiator is added into the reactor, and a reaction is conducted to obtain a reaction product; the obtained reaction product is washed with acetone, filtration is conducted, and then a filtration product is collected; the filtration product is dried in vacuum and then crushed to obtain white powder, that is, the high-temperature-resistant and salt-resistant filtrate loss reducer for the drilling fluid. The filtrate loss reducer prepared through the method is good in performance and temperature-resistant and salt-resistant effect, simple in processing technology and low in development cost.

Owner:YANGTZE UNIVERSITY

Wax-based binder for metal powder injection molding

The invention discloses a wax-based binder for metal powder injection molding. The wax-based binder comprises the following components: paraffin, E wax, polymethyl methacrylate moulding powder, an ethylene-vinyl acetate copolymer, high density polyethylene, stearic acid and an antioxidant BHT (butylated hydroxytoluene). The wax-based binder is prepared according to the following steps: putting metal powder into mixing equipment; then putting the paraffin, the E wax, the ethylene-vinyl acetate copolymer, the high density polyethylene, the stearic acid and the antioxidant BHT into the mixing equipment together, starting the mixing equipment and uniformly mixing the materials; dissolving the polymethyl methacrylate moulding powder to acetone to obtain a mixture, then putting the mixture into the mixing equipment, carrying out mixing operation till the binder is completely molten, and carrying out heat preservation for 8-12 minutes; discharging, cooling and then granulating, and feeding to finish the production of the wax-based binder. The binder disclosed by the invention is good in compatibility of components, free of phase separation, and easy to mold and remove, has the advantages of no pollution, no toxicity and the like and is especially applicable to production of Ni-Co-based products formed by metal powder injection molding.

Owner:SHANDONG JINZHU MATERIALS TECH

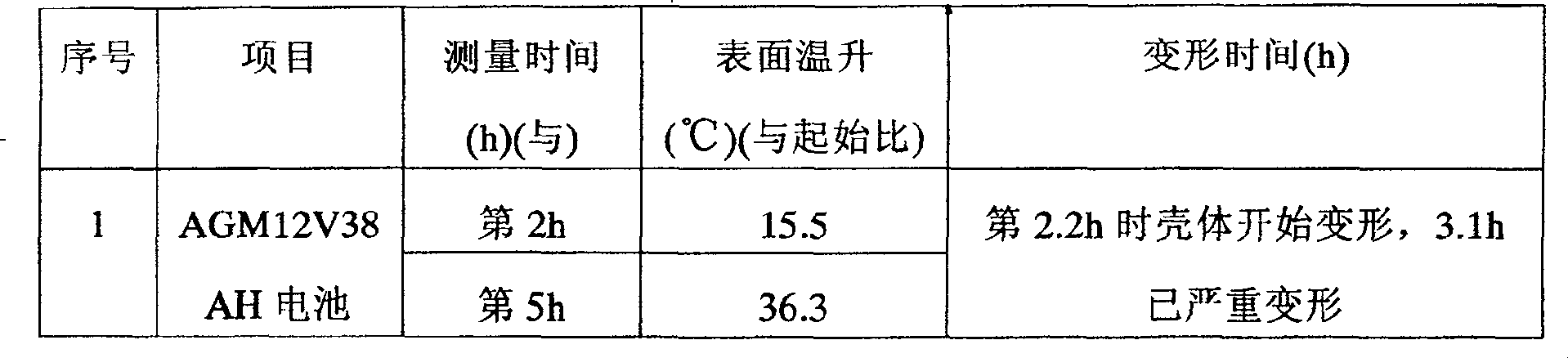

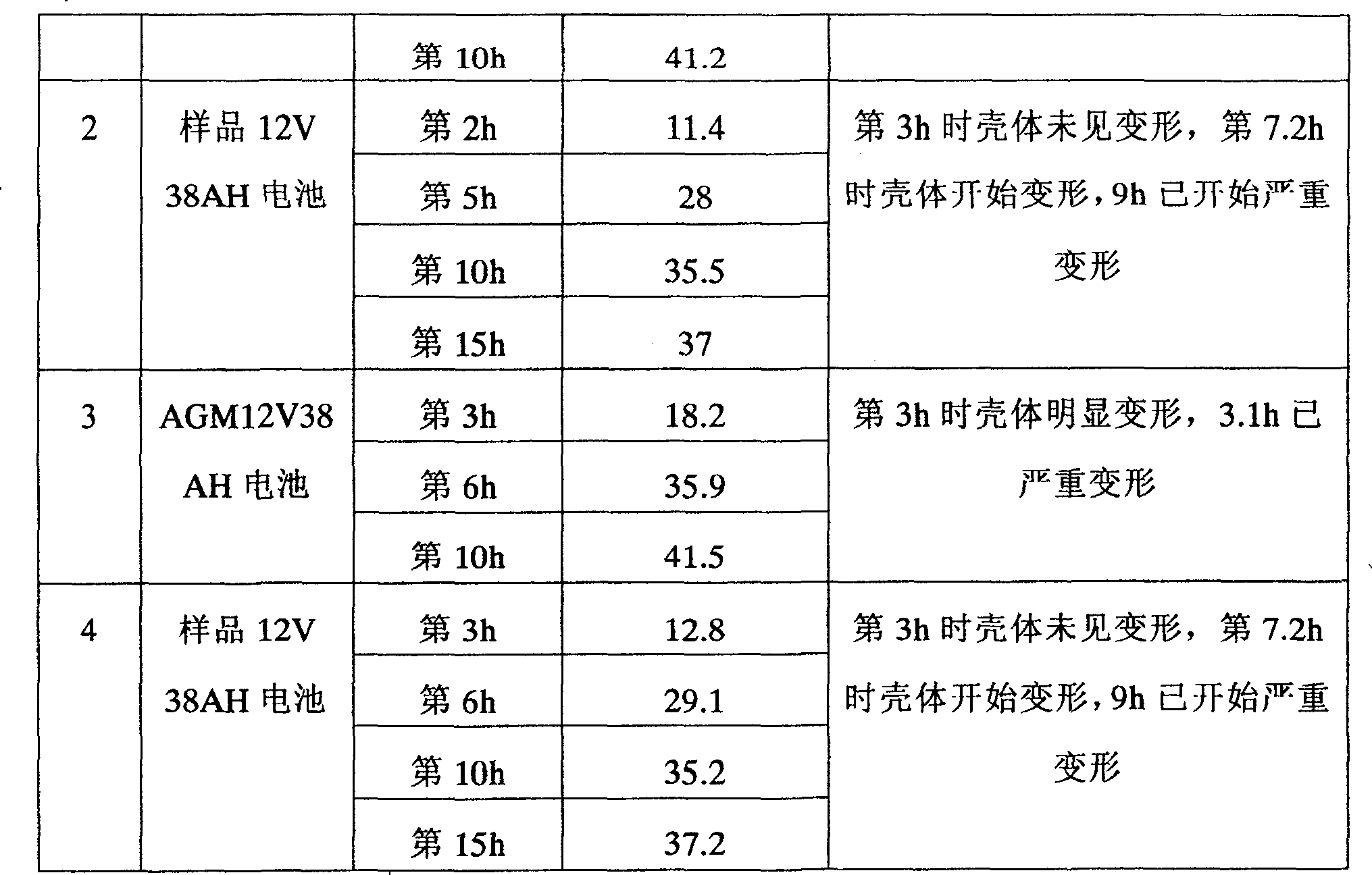

Nanometer-level high composite electrolyte and its preparing method

ActiveCN1767248ALarge heat capacityViscosity has little effectLead-acid accumulatorsElectrolytic agentChemical physics

Owner:深圳理士电源发展有限公司

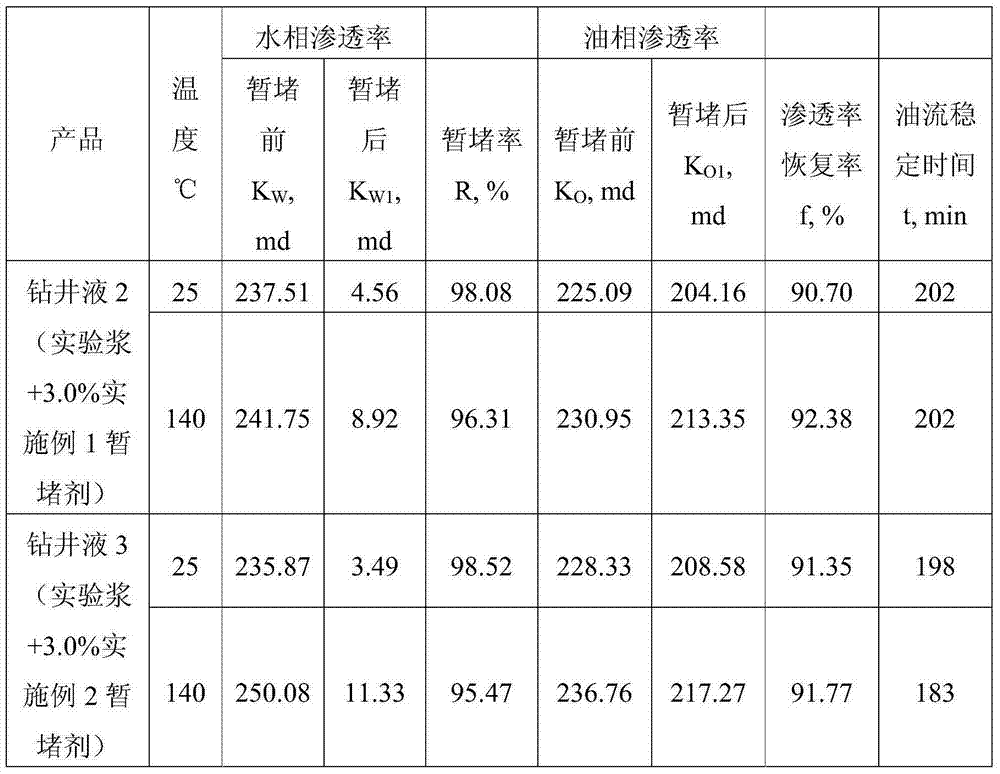

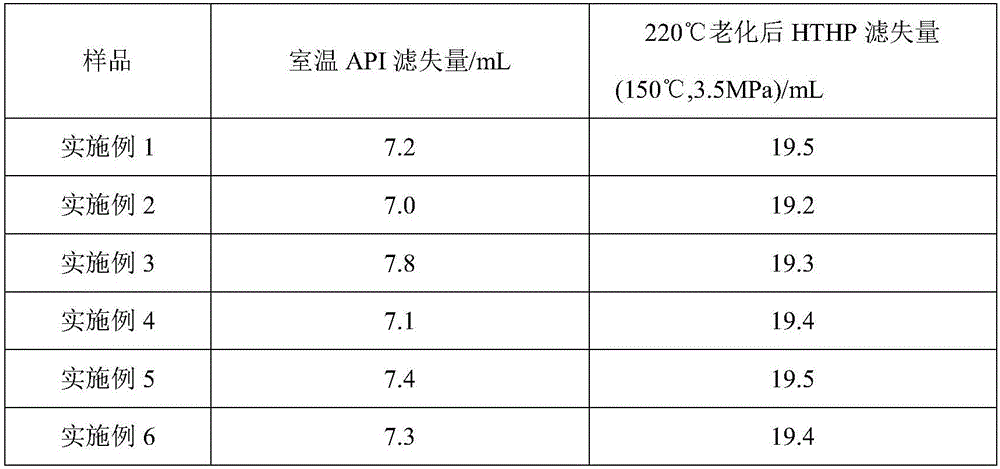

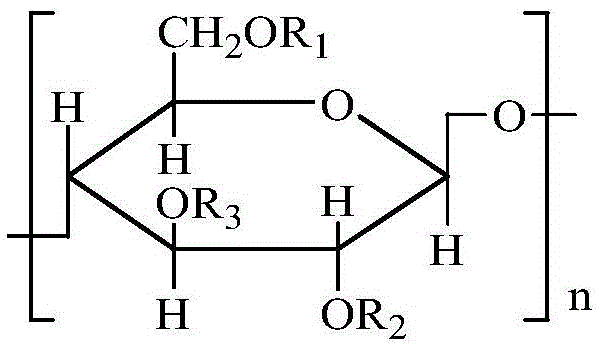

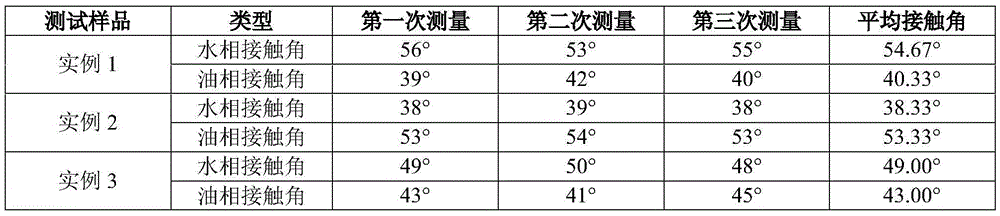

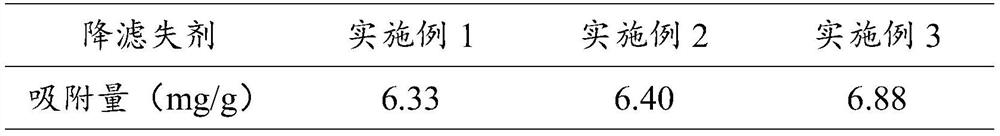

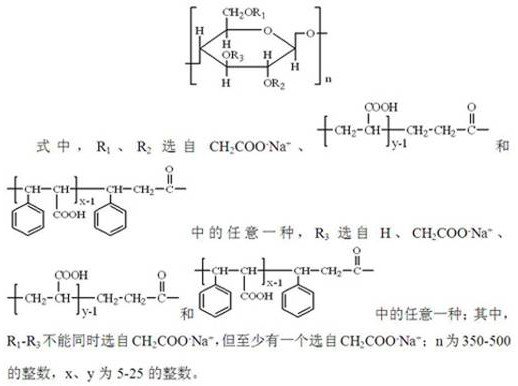

Amphiphilic starch filtrate reducer for water-based drilling fluid and preparation method thereof

ActiveCN106634880AImprove high temperature resistanceNo biological toxicityDrilling compositionWater basedChloroacetic acids

The invention provides an amphiphilic starch filtrate reducer for a water-based drilling fluid and a preparation method thereof, wherein the amphiphilic starch filtrate reducer has stronger high-temperature resistance, is resistant to divalent salt, and can effectively lower the filter loss of the water-based drilling fluid. The amphiphilic starch filtrate reducer for the water-based drilling fluid contains the following ingredients in parts by weight: 1,000 parts of starch, 200-500 parts of sodium hydroxide, 300-500 parts of chloroacetic acid, 200-400 parts of sodium carbonate, 300-600 parts of methyl alcohol, ethyl alcohol, propyl alcohol or isopropyl alcohol, 2,000-3,000 parts of water, 800-1,800 parts of hydrophobic monomer, 10-20 parts of an initiator and 0,5-1.0 part of chloroform. The amphiphilic starch filtrate reducer has higher high-temperature resistance, is resistant to univalent salt until the salt water is saturated, and resistant to the divalent salt until the concentration is 5.0%; the amphiphilic starch filtrate reducer has a certain oil-dispersing property, and can be used as the filtrate reducer of an oil-based drilling fluid; and the amphiphilic starch filtrate reducer has excellent compatibility with various drilling fluid treating agents.

Owner:CHINA PETROCHEMICAL CORP +3

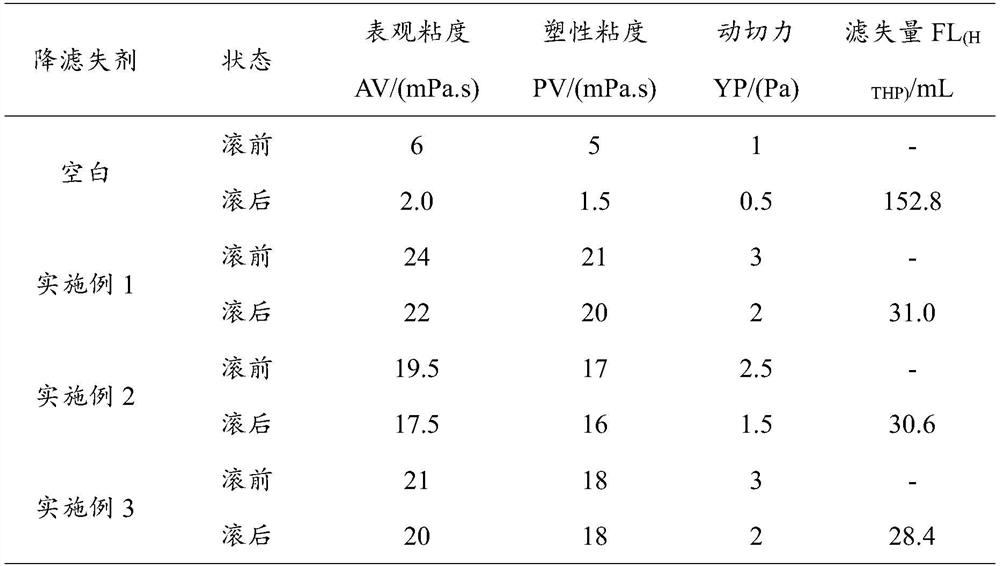

High-temperature-resistant filtrate reducer and preparation method thereof

ActiveCN113896830AImprove high temperature resistanceReduce manufacturing costDrilling compositionMeth-Silanes

The invention belongs to the technical field of drilling fluid additives, and provides a high-temperature-resistant filtrate reducer and a preparation method thereof. According to the preparation raw material sodium p-styrenesulfonate monomer of the high-temperature-resistant filtrate reducer, filtrate reducer molecules can have rigid large side groups, the steric hindrance of the filtrate reducer molecules is large, under the high-temperature condition, the molecular flexibility can be reduced, then molecular thermal motion is reduced, and finally the high-temperature-resistant performance of the filtrate reducer is improved. Compared with gamma-(methacryloyloxy) propyl trimethoxy silane and a gamma-(acrylamido) propyl triethoxy silane coupling agent, the vinyl trimethoxy silane disclosed by the invention is low in cost, and the preparation cost of the high-temperature-resistant filtrate reducer can be reduced. Besides, the vinyltrimethoxysilane is connected with the main chain of the filtrate reducer through a carbon-carbon bond, so that the defect that amide groups between other silane coupling agents and the main chain of the filtrate reducer are easy to decompose at high temperature is overcome, and the high-temperature resistance of the filtrate reducer is improved.

Owner:JINGZHOU JIAHUA TECH

Well cementation flushing fluid for oil-based drilling fluid and preparation method and use method of well cementation flushing fluid

InactiveCN110846013AImprove securitySimple recipeFlushingDrilling compositionActive agentDioxyethylene Ether

The invention discloses a well cementation flushing fluid for oil-based drilling fluid as well as a preparation method and a use method of the well cementation flushing fluid. The well cementation flushing fluid comprises fresh water, a nonionic surfactant I, a nonionic surfactant II, a normal salt cosolvent and an acidic salt cosolvent, wherein the nonionic surfactant I is a fatty alcohol-polyoxyethylene ether nonionic surfactant, and the nonionic surfactant II is a nonylphenol polyoxyethylene ether nonionic surfactant; the nonionic surfactant II has good emulsifying property, and an hydrophilic base end is easily adsorbed on the surfaces of an oil-water interface, a sleeve and a well wall; the non-ionic surfactant I is used as a main agent of the flushing fluid, has good wettability, foamability, detergency and emulsifying power, has relatively high degreasing capacity, hard water resistance, is easy to biodegrade and has good compatibility; the normal salt cosolvent and the acidic salt cosolvent are used for assisting dissolution of the two nonionic surfactants, and meanwhile, the elution capacity of the well cementation flushing fluid on drilling fluid and oil-based mud cake isenhanced; safety is high, the formula is simple, cost is low, and environment friendliness is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Novel environment-friendly resinous varnish

The invention discloses a novel environment-friendly resinous varnish, and relates to the technical field of varnish preparation. The novel environment-friendly resinous varnish is characterized by comprising the following components in percentage by weight: 5 to 15 percent of 2116 resin, 80 to 90 percent of soybean oil and 3 to 8 percent of cobalt. A preparation method of the novel environment-friendly resinous varnish comprises the following steps of: putting the 2116 resin and the soybean oil into a reaction kettle; when the temperature rises to 160+ / - 5 DEG C, keeping the temperature for half an hour; starting to add the cobalt slowly; and stirring uniformly and taking the mixture out of the kettle. The novel environment-friendly resinous varnish has the advantages of simple and feasible and safe preparation process, short production time and low cost. The varnish is light in color, clear and transparent, free from extraneous odor, and used for adjusting the fluidity of printing ink, has low influence on the viscosity of the printing ink with appreciated adding amount, also has no influence on the glossiness and the attachment fastness of the printing ink, and can be used for improving the aridity of the printing ink. The varnish has no component of petroleum-based mineral oil, the soybean oil replaces all petroleum-based solvents, the soybean oil has the characteristics of easy degradability, low toxicity and low volatile organic compounds (VOC) and the like, so the consumption of non-renewable resource, namely the mineral oil, in printing can be effectively reduced; and therefore, the environmental pollution is reduced.

Owner:安徽雅美油墨有限公司

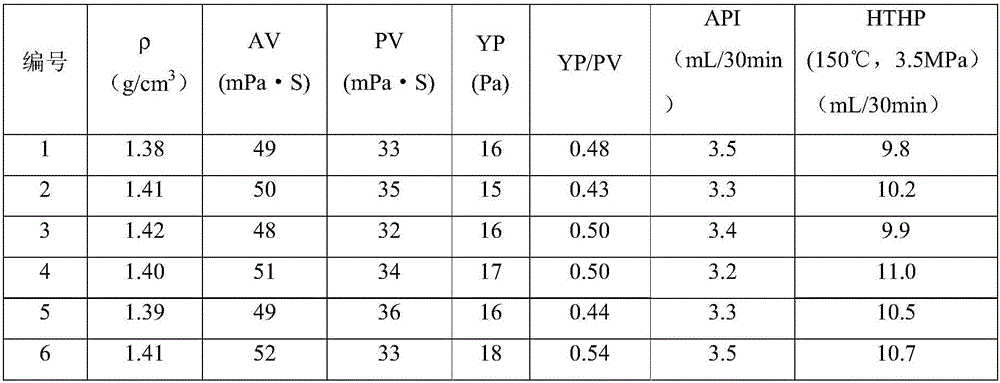

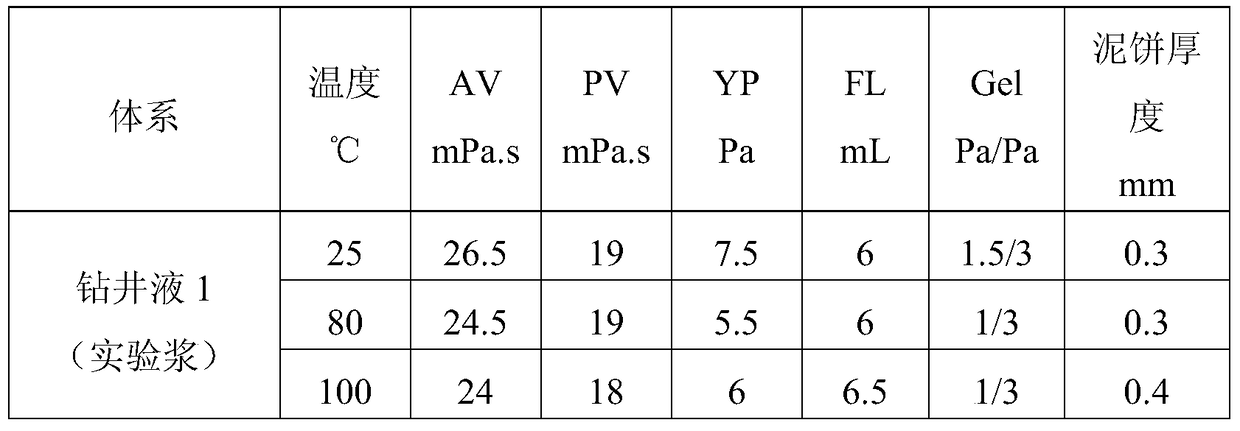

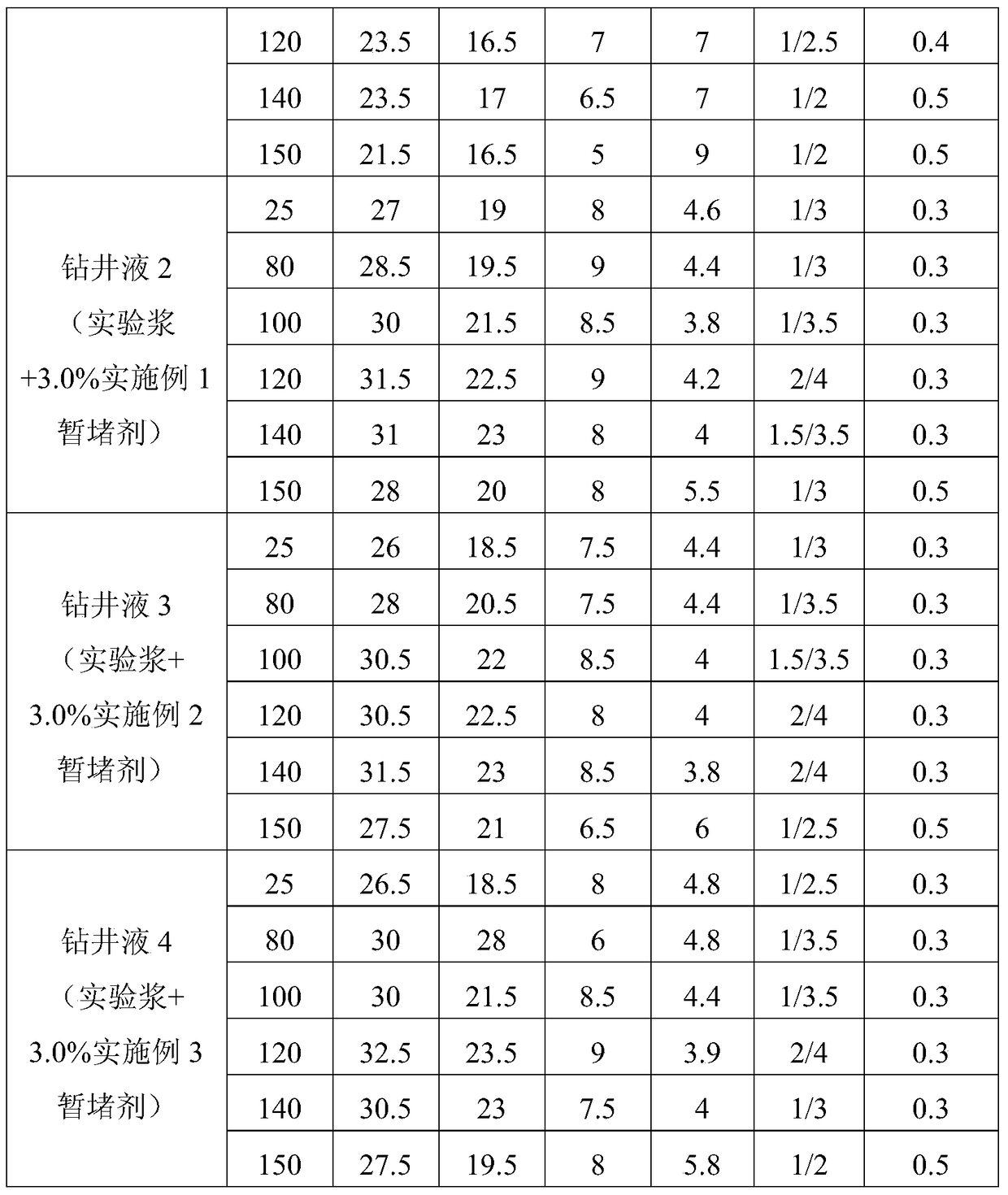

Drilling fluid as well as preparation method and application thereof

ActiveCN113861953AReduce manufacturing costImprove high temperature resistanceDrilling compositionBenzoyl peroxideVinyltriethoxysilane

The invention belongs to the technical field of drilling fluid, and provides drilling fluid as well as a preparation method and application thereof. The drilling fluid provided by the invention is an aqueous solution comprising the following components in percentage by mass: 4.0 to 6.0% of an organic silicon filtrate reducer, and 1.0 to 1.5% of an organic silicon inhibitor; the organic silicon filtrate reducer comprises the following preparation raw materials in parts by weight: 10 to 20 parts of acrylamide, 10 to 20 parts of diallyldimethylammonium chloride, 10 to 20 parts of sodium p-styrenesulfonate, 1 to 1.5 parts of vinyl trimethoxy silane and 0.1 to 0.2 part of benzoyl peroxide. The organic silicon inhibitor comprises the following preparation raw materials in parts by weight: 10 to 15 parts of vinyltriethoxysilane and 100 to 150 parts of hyperbranched polyethyleneimine. Due to the use of the organic silicon filtrate reducer and the organic silicon inhibitor, the obtained drilling fluid has excellent filtrate reduction property and inhibition property at high temperature, and can be applied to an easily unstable shale high-temperature stratum.

Owner:JINGZHOU JIAHUA TECH

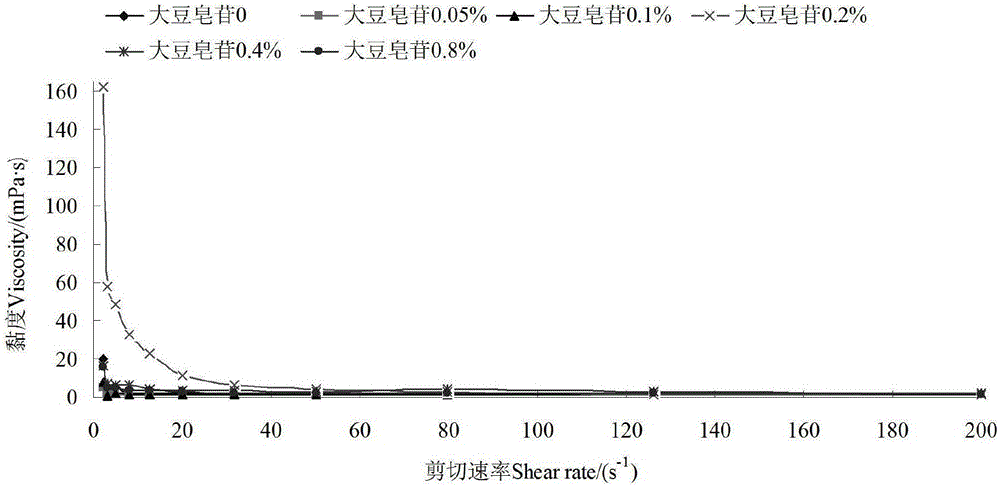

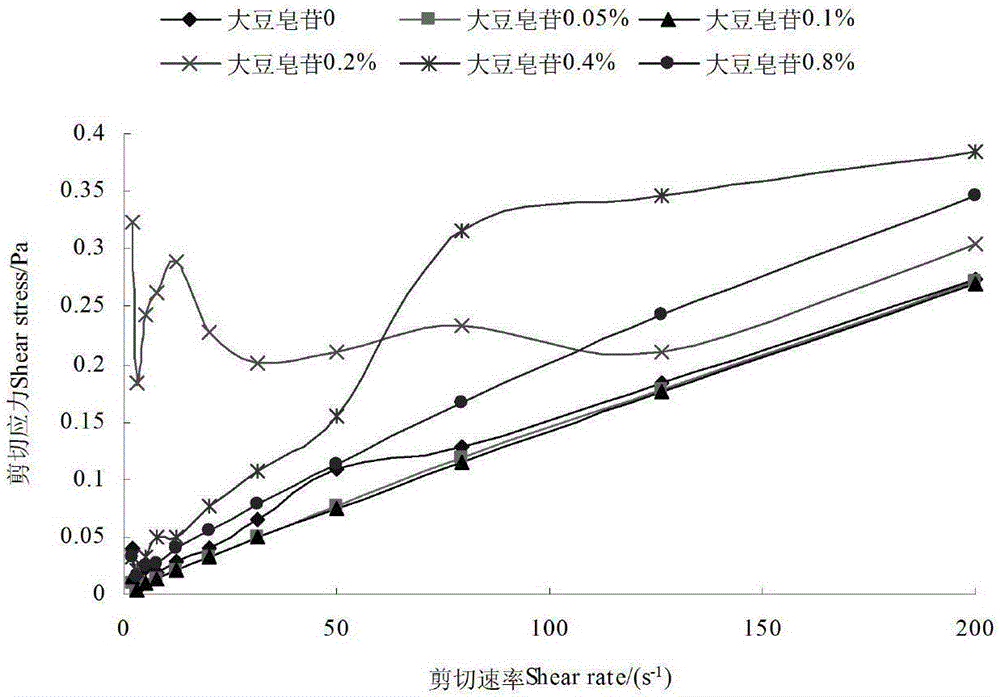

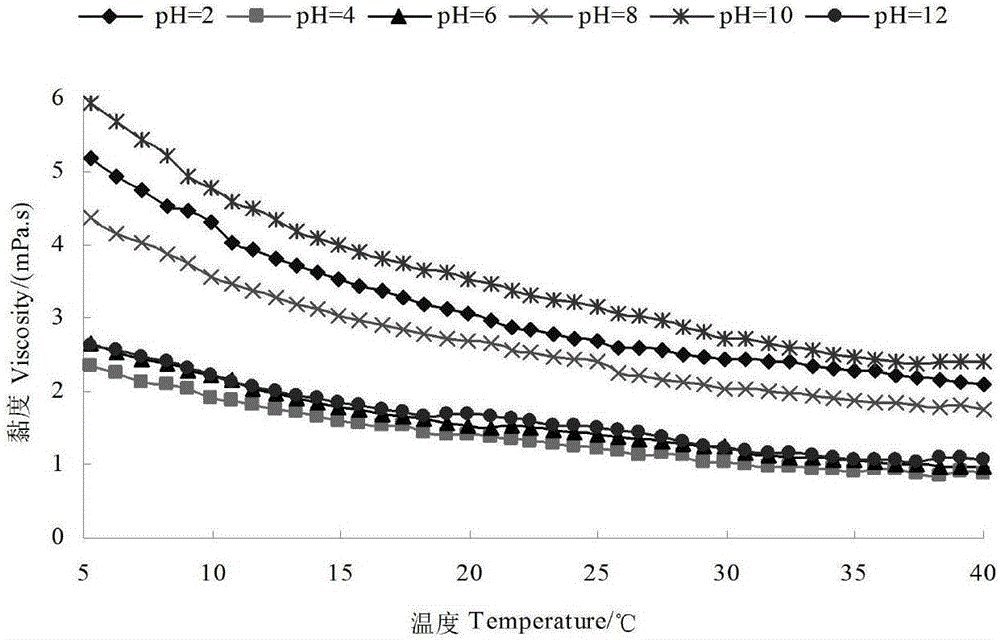

Method for analyzing interaction between saponin and protein

InactiveCN106596873AViscosity has little effectViscosity changes smoothlyTesting foodShear stressPhosphate

The invention provides a method for analyzing interaction between saponin and protein. The method comprises the following steps: 1) protein, saponin and a phosphate buffer are mixed, and a to-be-tested sample is obtained; 2) the viscosity or / and shear stress of the to-be-tested sample obtained in the step 1) is / are detected with a rheological method; 3) the interaction between the saponin and the protein is obtained according to the relation between the viscosity or / and shear stress, obtained in the step 2), of the to-be-tested sample and the viscosity or / and shear stress, obtained in advance, of a protein phosphate buffer and a saponin phosphate buffer. The mode of interaction between the saponin and the protein adopts hydrogen bond and hydrophobic interaction.

Owner:BOHAI UNIV

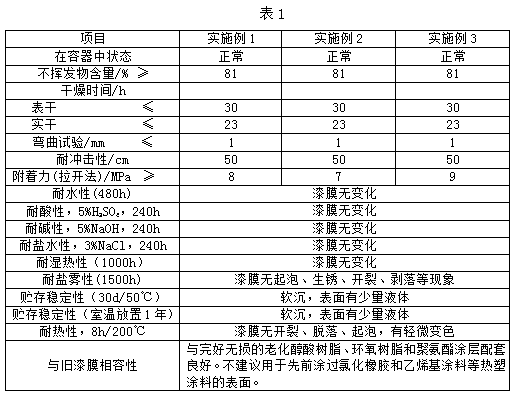

Multifunctional low surface treatment epoxy thick build long-acting anticorrosion primer and preparation method thereof

ActiveCN108690468BHigh fullnessGood flexibilityAnti-corrosive paintsEpoxy resin coatingsChemical industrySlurry

The invention discloses a multifunctional low-surface treatment epoxy thick slurry long-effect anticorrosive primer, and belongs to the field of chemical industry. The multifunctional low-surface treatment epoxy thick slurry long-effect anticorrosive primer is prepared from a component A and a component B, wherein a mixed system formed by high-molecular-weight epoxy resin and low-molecular-weightepoxy resin in a bisphenol A type has high low-temperature solid-containing performance, superior corrosion resistance, high adhesive force, flexibility and salt spray resistance. The multifunctionallow-surface treatment epoxy thick slurry long-effect anticorrosive primer integrates stability, permeability and transformation. According to the method, a basket type grinding-dispersing method and ahigh-speed stirring-dispersing method are combined for preparing the thick slurry primer, so that the production table time can be shortened, the production efficiency is increased, the production cost is saved, and the obtained product has high storage stability, and is free from the quality problems of lamination and precipitation.

Owner:西北永新涂料有限公司

Fiber material modified melamine formaldehyde foam and preparation method thereof

The invention discloses fiber material modified melamine formaldehyde foam. The foam is formed by solution foaming of the following constituents in parts by weight: 100 parts of fiber material modified melamine formaldehyde resin solution, 0.2-8 parts of a surface active agent, 1-30 parts of a foaming agent and 1-10 parts of a curing agent, wherein the content of the fiber material is 0.2-10% of the sum of the mass of the formaldehyde solution and the melamine before polymerization of the resin solution. The invention further discloses a preparation method of the melamine formaldehyde foam. The melamine formaldehyde foam provided by the invention is excellent in fire resistance, and the mechanical properties, such as flexibility and compression strength, of the foam are also improved greatly; and moreover, the preparation method of the foam is simple and easy to carry out, and the production cost is low, large-scale popularization and application of the foam are facilitated.

Owner:SICHUAN UNIV

A kind of preparation method of amphiphilic starch fluid loss reducer for water-based drilling fluid

ActiveCN106634880BImprove high temperature resistanceNo biological toxicityDrilling compositionWaxy cornWell drilling

The invention relates to a preparation method of an amphiphilic starch fluid loss reducer for water-based drilling fluid used in the drilling process of oil exploration wells and production wells. It is formed by first reacting waxy cornstarch with a hydrophilic modifier, and then grafting hydrophobic monomers onto the waxy cornstarch through free polymerization. Compared with the prior art, the present invention has the following advantages: the amphiphilic starch fluid loss reducer has higher high temperature resistance and can be used at 130-150°C; Salt to 5.0%; amphiphilic starch has little effect on the viscosity of drilling fluid; amphiphilic starch can be completely biodegraded, has no biological toxicity, and has no impact on the environment; has certain oil dispersibility, and can be used as a filter reducer for oil-based drilling fluid loss agent; amphiphilic starch has good compatibility with various drilling fluid treatment agents.

Owner:CHINA PETROCHEMICAL CORP +3

Self-removing plugging and anti-temperature temporary plugging agent for water-based drilling fluid and preparation method thereof

ActiveCN104710967BHigh temperature resistanceSignificant temporary blocking effectDrilling compositionWater basedAcid washing

The invention provides a self-plugging releasing temperature resistant temporary plugging agent used for water-based drilling fluid, the self-plugging releasing temperature resistant temporary plugging agent comprises nano calcium carbonate and a product which is obtained by reacting starch, alkali metal hydroxide, halogenated organic acid, carbonate, a hydrophobic modification agent and alcohol with water. The invention also provides a preparation method of the self-plugging releasing temperature resistant temporary plugging agent used for the water-based drilling fluid, and the self-plugging releasing temperature resistant temporary plugging agent used for the water-based drilling fluid can be obtained by proportionally adding components into a kneading machine for kneading. The self-plugging releasing temperature resistant temporary plugging agent has strong high temperature resistance, and can resist the temperature up to 140 DEG C; and the self-plugging releasing temperature resistant temporary plugging agent has good temporary plugging effect and significant reservoir protection effect, and the water-based drilling fluid added with the temporary plugging agent has high temporary plugging rate and oil phase permeability recovery rate; at the same time, the temporary plugging agent has self-plugging releasing ability. During the late flowback, the self-plugging releasing can be realized by formation of a hydrophobic channel without acid washing for mud cake removal and other processes, and secondary damage to a reservoir can be avoided.

Owner:CHINA PETROCHEMICAL CORP +1

Wax-based binder for metal powder injection molding

The invention discloses a wax-based binder for metal powder injection molding. The wax-based binder comprises the following components: paraffin, E wax, polymethyl methacrylate moulding powder, an ethylene-vinyl acetate copolymer, high density polyethylene, stearic acid and an antioxidant BHT (butylated hydroxytoluene). The wax-based binder is prepared according to the following steps: putting metal powder into mixing equipment; then putting the paraffin, the E wax, the ethylene-vinyl acetate copolymer, the high density polyethylene, the stearic acid and the antioxidant BHT into the mixing equipment together, starting the mixing equipment and uniformly mixing the materials; dissolving the polymethyl methacrylate moulding powder to acetone to obtain a mixture, then putting the mixture into the mixing equipment, carrying out mixing operation till the binder is completely molten, and carrying out heat preservation for 8-12 minutes; discharging, cooling and then granulating, and feeding to finish the production of the wax-based binder. The binder disclosed by the invention is good in compatibility of components, free of phase separation, and easy to mold and remove, has the advantages of no pollution, no toxicity and the like and is especially applicable to production of Ni-Co-based products formed by metal powder injection molding.

Owner:SHANDONG JINZHU MATERIALS TECH

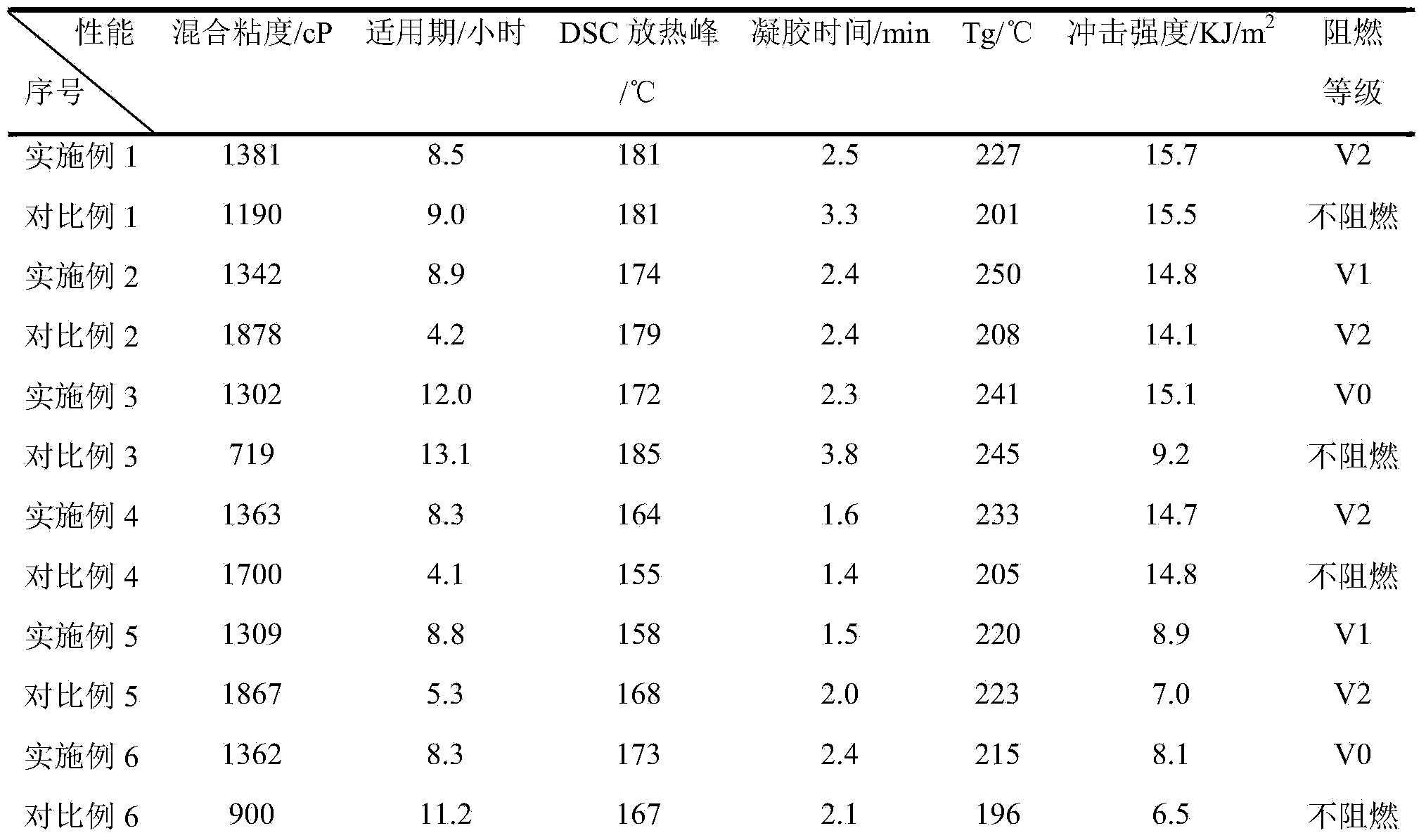

A kind of flame retardant and high temperature resistant epoxy resin composition that can be used for pultrusion molding and preparation method

ActiveCN104004320BImprove high temperature resistanceBalance of high temperature resistanceFire retardantPolymer chemistry

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

A kind of LED chip insulating and heat-conducting crystal-bonding adhesive and preparation method thereof

ActiveCN107974232BViscosity has little effectImprove thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesPtru catalystAdhesive

The invention belongs to the technical field of adhesives, and in particular relates to an insulating heat-conducting crystal-bonding adhesive for LED chips and a preparation method thereof. The special thermally conductive filler of the present invention is a mixture of thermally conductive fillers of different shapes, such as needle-shaped, flake-shaped or spherical. By pre-mixing the needle-shaped and spherical thermally-conductive fillers with a certain amount of connecting agent, the needle-shaped and spherical thermally-conductive fillers The fillers are connected together to form a certain three-dimensional structure, and then mixed with resin, crosslinking agent, catalyst, adhesive, etc., so that there is no distance between the thermally conductive fillers within a certain range, and the thermal conductivity is high. When the amount of filler is not high, it has little effect on the viscosity of the colloid, and has excellent bonding performance, which can significantly increase its thermal conductivity, thereby achieving the purpose of increasing the conduction efficiency.

Owner:YANTAI DARBOND TECH

A kind of epoxy resin fullerene composite material and preparation method thereof

ActiveCN105255112BAvoid transmissionImprove insulation performancePlastic/resin/waxes insulatorsEpoxyElectrical aging

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Anti-settling agent for water-based baking paint as well as preparation method and application of anti-settling agent

The invention relates to the technical field of anti-aging agents for paint, in particular to an anti-settling agent for water-based baking paint as well as a preparation method and an application of the anti-settling agent. The anti-settling agent for the water-based baking paint is prepared from raw materials in parts by weight as follows: 50-200 parts of monohydric alcohol, 10-70 parts of polyol, 50-150 parts of phosphorus pentoxide, 50-150 parts of metal saponated matter, 0.5-2 parts of an antioxidant, 20-250 parts of an organic amine neutralizer and 100-300 parts of a solvent. The anti-settling agent for the water-based baking paint can solve the problems of precipitation and caking of filler in a water-based baking paint system, is simple to apply, good in anti-setting effect and effective as well for the large-density filler, and has no obvious influence on system viscosity.

Owner:东莞市隆海新材料科技有限公司

Resinous varnish used for printing ink

The invention discloses a resinous varnish used for printing ink. The resinous varnish is composed of following ingredients, by weight, 10 to 20 parts of 2116 rosin modified phenolic resin, 4 to 6 parts of metallic cobalt, 20 to 30 parts of peanut oil, 1 to 3 parts of xylitol, 3 to 5 parts of clove oil, 1 to 3 parts of white carbon black, 2 to 4 parts of grape seed oil, 2 to 4 parts of nano aluminium powder, 4 to 6 parts of stearic acid, 1 to 3 parts of metallic titanium, 1 to 3 parts of azelaic acid, 1 to 2 parts of turanose, and 1 to 2 parts of tert-butylamine. The resinous varnish contains no petroleum-based mineral oil; petroleum-based solvents are all replaced by soya-bean oil; soya-bean oil is easily degradable, is low in toxicity and VOC, and is capable of reducing consumption of non-renewable resource, mineral oil, in printing; so that environmental pollution is reduced.

Owner:陆开云

Nanometer-level high composite electrolyte and its preparing method

ActiveCN100483833CLarge heat capacityViscosity has little effectLead-acid accumulatorsComposite electrolyteColloid

Owner:深圳理士电源发展有限公司

A kind of graphene oxide modified led heat conduction potting glue and preparation method thereof

ActiveCN106753208BImprove thermal conductivityViscosity has little effectNon-macromolecular adhesive additivesMacromolecular adhesive additivesPtru catalystHeat conducting

The invention relates to graphene oxide modified organic silicon heat conducting pouring sealant for an LED electronic product and a preparation method of the graphene oxide modified LED heat conducting pouring sealant. The preparation method comprises the following steps: uniformly dispersing graphene oxide and vinyl-base polydimethylsiloxane in a vacuum kneading machine, adding a surface modified heat conducting filler, dehydrating and blending for 50 to 100 minutes at the temperature of 70 to 100 DEG C and a vacuum degree of 0.07 to 0.09 MPa, thus obtaining a base material; adding a hydrogen-containing silicone oil and a cross-linking inhibitor into the base material at a normal temperature, sufficiently stirring for 20 to 40 minutes to obtain a component A; adding a platinum catalyst into the base material at a normal temperature, and sufficiently stirring for 20 to 40 minutes to obtain a component B; uniformly blending the component A and the component B of a same amount, defoaming for 6 to 12 minutes at the vacuum degree of 0.05 to 0.07 MPa, thus obtaining the graphene oxide modified LED heat conducting pouring sealant. The pouring sealant has appropriate viscosity, the heat conducting coefficient is 1.1 to 1.4 w / m.k, a cured product has good mechanical performance and electric performance, can be cured at a normal temperature or can be heated to be cured, and can be widely used for encapsulating integrated electronic elements and devices, high-power chips, integrated circuit boards, circuit modules and the like with high heat dissipation requirement.

Owner:BEIJING UNIV OF CHEM TECH

A kind of preparation method of solvent-free environment-friendly silicone resin for glass fiber bonding

ActiveCN103484057BWill not polluteReduce consumptionNon-macromolecular adhesive additivesGlass fiberOrganic solvent

The invention provides a preparation method of silicone resin for adhesion of solvent-free environment-friendly glass fiber. The preparation method comprises the steps of (1) preparing solvent-free vinyl MDTQ silicone resin; (2) preparing vinyl phenyl silicone oil; (3) adding the vinyl MDTQ silicone resin, the vinyl phenyl silicone oil and precipitation method silicon dioxide into a reaction kettle according to the proportion of (2-4): (5-7): (1-2) in parts by weight, heating to 150-200 DEG C under stirring conditions, performing heat preservation for 2h, cooling and discharging to obtain base glue; (4) taking 100 parts by weight of the base glue, adding 8-6 parts by weight of hydrogen-containing silicone oil with the hydrogen content of 0.2-1%, uniformly stirring, and then packaging to obtain a component A; (5) taking 100 parts by weight of the base glue, adding 0.5-2 parts by weight of platinum complex catalyst, uniformly stirring, and then packaging to obtain a component B. When the A-B dual-component solvent-free silicone resin prepared by the preparation method provided by the invention is coated, organic solvents do not need to be added, the coating efficiency is improved, and the environmental pollution can be avoided.

Owner:襄阳玖润氟硅材料有限公司

Powder environment-friendly heat stabilizer for slush molding products

The invention relates to the technical field of preparation of heat stabilizers, in particular to an environment-friendly powder heat stabilizer for slush molding products. The heat stabilizer is prepared from the following components in parts by weight: 15-25 parts of powdery zinc stearate, 10-20 parts of calcium stearate, 15-25 parts of an acid acceptor, 1-5 parts of an antioxidant, 5-10 parts of an auxiliary stabilizer, 5-10 parts of a coupling agent and 10-20 parts of a filling agent. Compared with a traditional liquid stabilizer, the powder stabilizer for PVC slush molding has the advantages that introduction of solvent oil with strong volatility is avoided by preferably selecting a powder material, generation of volatile odor is greatly reduced, and compared with the traditional liquid stabilizer, the powder stabilizer for PVC slush molding has the advantages that the compatibility is equivalent to that of PVC paste resin and a plasticizer, influence on colloid viscosity is small, and the heat resistance of the prepared powder stabilizer for PVC slush molding is greatly improved by scientifically proportioning the material proportion.

Owner:嘉兴若天新材料科技有限公司

Liquid crystal backlight light guide plate self-adhesive protective film and production method thereof

ActiveCN112538318AViscosity has little effectMeet protection needsFilm/foil adhesivesOther rubber adhesivesLow-density polyethylenePolymer science

The invention relates to a liquid crystal backlight source light guide plate self-adhesive protective film and a production method thereof, and belongs to the field of thin film materials, the protective film is composed of a self-adhesive layer, a middle layer and an unwinding layer which are connected in sequence; wherein the self-adhesive layer comprises 70-80 parts by mass of low-density polyethylene and 20-30 parts by mass of soft rubber resin, the middle layer comprises 40-60 parts by mass of low-density polypropylene and 40-60 parts by mass of high-density polyethylene, and the unwinding layer comprises 40-55 parts by mass of block copolymer polypropylene, 40-55 parts by mass of low-density polyethylene and 2-5 parts by mass of an opening agent. Compared with the existing protectivefilm, the self-adhesive protective film prepared by the invention can be torn down to be re-adhered after being adhered to the light guide plate, the adhesive force is stable, the change of the adhesive force is small, meanwhile, the influence of the change of the temperature on the adhesive force of the protective film is small, the adhesive force is controlled within a standard range, and the normal production and processing requirements can be met.

Owner:永新股份(黄山)包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com