A kind of LED chip insulating and heat-conducting crystal-bonding adhesive and preparation method thereof

A LED chip, insulation and heat conduction technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of low thermal conductivity, restricting the application effect, and limited addition of heat-conducting fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

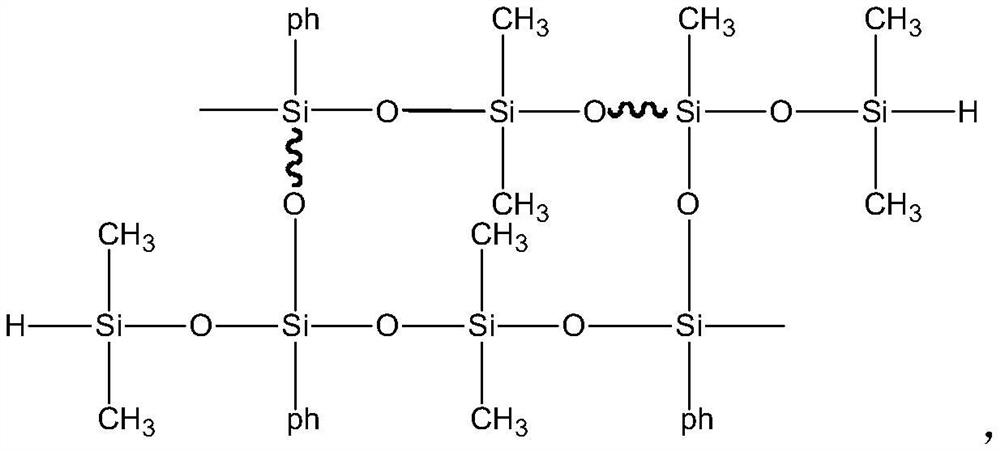

[0044] An insulating heat-conducting crystal-bonding adhesive for LED chips, the components of which include in parts by weight: 60 parts of polysiloxane resin containing vinyl organosilicon, 35 parts of hydrogen-containing silicone oil crosslinking agent, 0.3 parts of platinum catalyst Karstedt, nano 9 parts of titanium dioxide adhesive and 150 parts of special thermal conductive filler.

[0045] The preparation method of the above-mentioned LED chip insulation and heat-conducting crystal-bonding glue, the steps are as follows:

[0046] (1) Preparation of special thermally conductive filler

[0047] a. Add 100 parts of thermally conductive filler alumina (needle shape) into the high-speed disperser, add 1 part of linking agent, mix evenly, and store in airtight;

[0048] b. Add 100 parts of thermally conductive filler hexagonal boron nitride (spherical) into the high-speed disperser, add 0.2 parts of linking agent, mix evenly, and store in airtight;

[0049] c. Add the alum...

Embodiment 2

[0052] An insulating heat-conducting crystal-bonding adhesive for LED chips, the components of which include, in parts by weight: 80 parts of polysiloxane resin containing vinyl organosilicon, 45 parts of hydrogen-containing silicone oil crosslinking agent, 0.2 parts of platinum catalyst Karstedt, nano 8 parts of titanium dioxide adhesive and 120 parts of special thermal conductive filler.

[0053] The preparation method of the above-mentioned LED chip insulation and heat-conducting crystal-bonding glue, the steps are as follows:

[0054] (1) Preparation of special thermally conductive filler

[0055] a. Add 50 parts of thermally conductive filler alumina (flaky) into the high-speed disperser, add 0.5 parts of linking agent, mix evenly, and store in airtight;

[0056] b. Add 100 parts of thermally conductive filler hexagonal boron nitride (spherical) into the high-speed disperser, add 0.2 parts of linking agent, mix evenly, and store in airtight;

[0057] c. Add the aluminum...

Embodiment 3

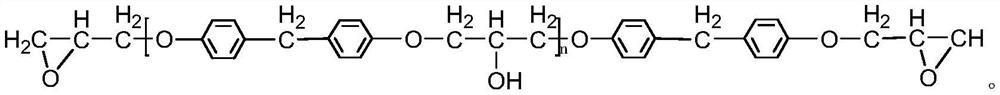

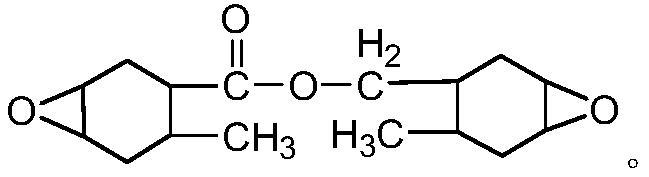

[0060] An insulating heat-conducting crystal-bonding adhesive for LED chips, the components of which include, in parts by weight: 40 parts of E51 bisphenol A epoxy resin, 40 parts of alicyclic epoxy resin, and 85 parts of methyltetrahydrophthalic anhydride , 0.2 parts of 2-methylimidazole catalyst, 5 parts of nano-titanium dioxide adhesive and 180 parts of special thermally conductive filler.

[0061] The preparation method of the above-mentioned LED chip insulation and heat-conducting crystal-bonding glue, the steps are as follows:

[0062] (1) Preparation of special thermally conductive filler

[0063] a. Add 100 parts of thermally conductive filler alumina (needle shape) into the high-speed disperser, add 1 part of linking agent, mix evenly, and store in airtight;

[0064] b. Add 100 parts of thermally conductive filler alumina (spherical) into the high-speed disperser, add 1 part of linking agent, mix evenly, and store in airtight;

[0065] c. Add the alumina (needle-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com