High-temperature-resistant and salt-resistant filtrate loss reducer for drilling fluid and preparation method and application of filtrate loss reducer

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high price, high temperature resistance, salt resistance limitation, long reaction time, etc., and achieve high performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

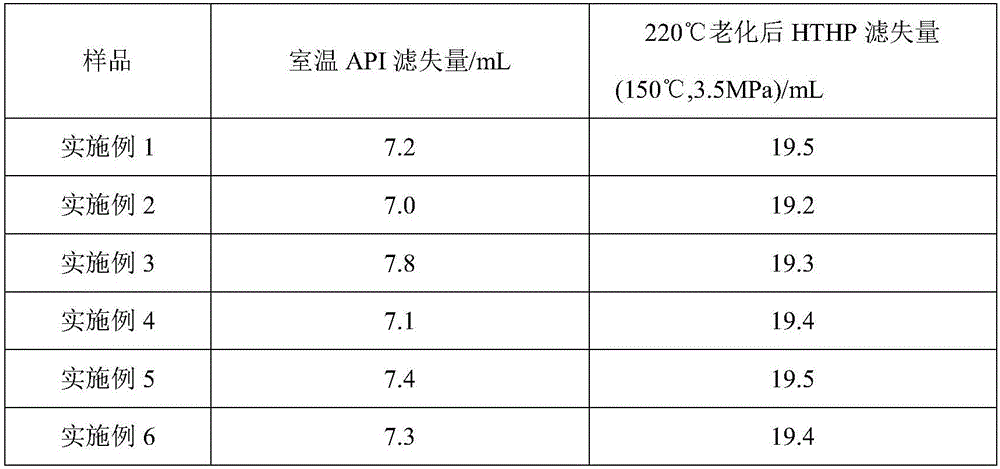

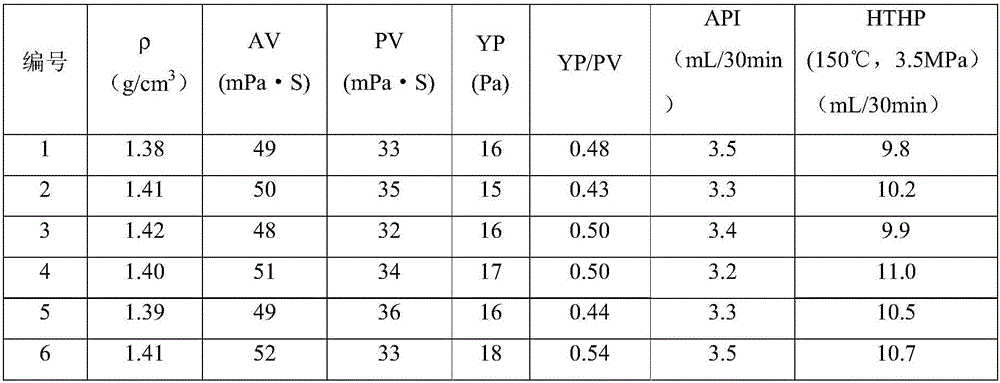

Examples

Embodiment 1

[0032] A high-temperature and salt-resistant fluid loss reducer for drilling fluid, the preparation method of which is as follows:

[0033] (1) Add 10 parts of 2-acrylamide-2-methylpropanesulfonic acid and 20 parts of water into the reactor, stir to fully dissolve 2-acrylamide-2-methylpropanesulfonic acid in water;

[0034] (2) Add 10 parts of acrylic acid to the aqueous solution of 2-acrylamide-2-methylpropanesulfonic acid to form a mixture A, then add a pH regulator to the mixture A, and adjust the pH value of the mixture A to 7;

[0035] (3) Heating the reactor so that the temperature of the mixture A in the reactor is maintained at 45°C, then adding 4 parts of N-isopropylacrylamide and 3.5 parts of nano-calcium bentonite to the mixture A, and stirring evenly to obtain the mixture B;

[0036] (4) Add 0.7 parts of initiator to the mixture B, and react for 60 min at 45° C. to obtain a reaction product;

[0037] (5) washing the reaction product obtained in step (4) with aceto...

Embodiment 2

[0040] A high-temperature and salt-resistant fluid loss reducer for drilling fluid, the preparation method of which is as follows:

[0041] (1) Add 2 parts of 2-acrylamide-2-methylpropanesulfonic acid and 25 parts of water into the reactor, stir to fully dissolve 2-acrylamide-2-methylpropanesulfonic acid in water;

[0042] (2) Add 15 parts of acrylic acid to the aqueous solution of 2-acrylamide-2-methylpropanesulfonic acid to form a mixture A, then add a pH regulator to the mixture A, and adjust the pH value of the mixture A to 8;

[0043] (3) Heating the reactor so that the temperature of the mixture A in the reactor is maintained at 40° C., then adding 3 parts of N-isopropylacrylamide and 2.5 parts of nano-calcium bentonite to the mixture A, and stirring evenly to obtain the mixture B;

[0044] (4) Add 0.6 parts of initiator to the mixture B, and react for 70 minutes at 40° C. to obtain a reaction product;

[0045] (5) washing the reaction product obtained in step (4) with ...

Embodiment 3

[0048] A high-temperature and salt-resistant fluid loss reducer for drilling fluid, the preparation method of which is as follows:

[0049] (1) Add 20 parts of 2-acrylamide-2-methylpropanesulfonic acid and 45 parts of water into the reactor, stir to fully dissolve 2-acrylamide-2-methylpropanesulfonic acid in water;

[0050] (2) Add 20 parts of acrylic acid to the aqueous solution of 2-acrylamide-2-methylpropanesulfonic acid to form a mixture A, then add a pH regulator to the mixture A, and adjust the pH value of the mixture A to 9;

[0051] (3) Heating the reactor so that the temperature of the mixture A in the reactor is maintained at 50° C., then adding 4 parts of N-isopropylacrylamide and 7 parts of nano-calcium bentonite to the mixture A, and stirring evenly to obtain the mixture B;

[0052] (4) Add 0.7 parts of initiator to the mixture B, and react for 50 minutes at 50° C. to obtain a reaction product;

[0053] (5) washing the reaction product obtained in step (4) with ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com