A kind of flame retardant and high temperature resistant epoxy resin composition that can be used for pultrusion molding and preparation method

An epoxy resin and pultrusion molding technology, applied in the field of polymer chemical industry, can solve the problems of lowering the glass transition temperature, difficulty in use, and sharp increase in resin viscosity, etc., and achieve the effect of Tg improvement, good cost advantage, and superior high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

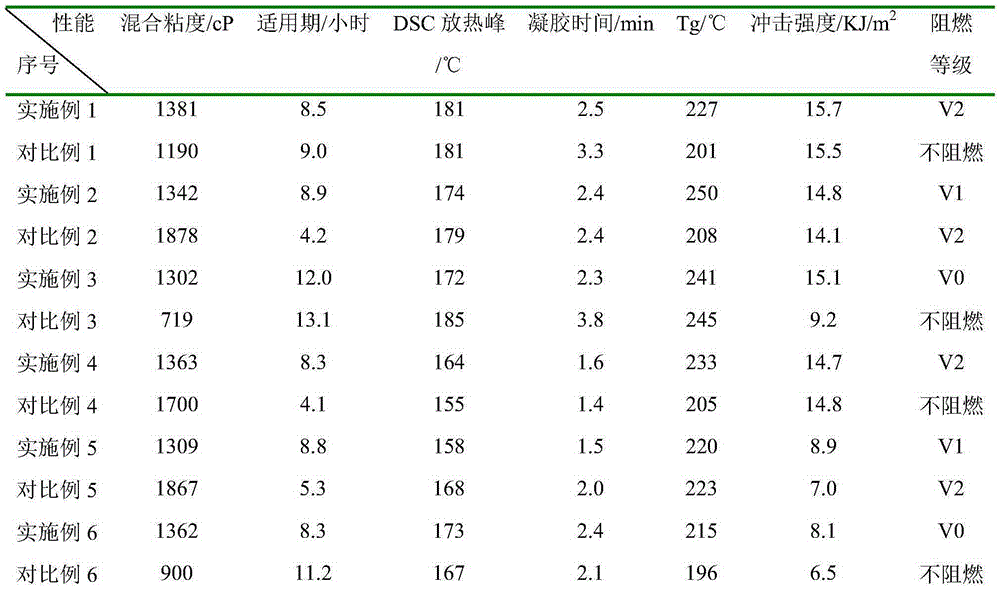

Examples

Embodiment 1

[0056] 3 parts of E-51, 2 parts of NPEF-170, 5 parts of GE-30 and 90 parts of CEL-2021P were prepared according to the above resin A preparation method to obtain resin A component; 55 parts of methyl hexahydrophthalic anhydride, 12 parts Phenone tetracarboxylic dianhydride, 8 parts of PFNH9880, 23 parts of Ricon-130MA-13, 1.2 parts of polymethylphenylsiloxane and 0.8 parts of iron acetylacetonate were prepared according to the above method of curing agent B to obtain curing agent group B points; 99 parts of ultra-fine particle size magnesium hydroxide LHN-01, 0.8 parts of CG-560, and 0.2 parts of stearic acid were prepared according to the method of the above-mentioned flame retardant modifier C component to obtain the C component.

[0057] Mix components A, B and C in a ratio of A:B:C=100:128:20 to obtain a flame retardant and high temperature resistant epoxy resin composition. Gel test, viscosity test, pot life test, exothermic peak test; prepare resin composition cast body ...

Embodiment 2

[0063] 2 parts of E-51, 20 parts of NPCN-704, 2 parts of GE-30 and 76 parts of TDE-85 were prepared according to the above resin A preparation method to obtain resin A component; 69 parts of methyl endomethylene tetrahydro Phthalic anhydride, 7 parts of benzophenone tetracarboxylic dianhydride, 1 part of PFNH9880, 20 parts of Ricon-130MA-13, 2 parts of polymethylphenylsiloxane and 1 part of iron acetylacetonate were prepared according to the method of curing agent B above. Curing agent component B: 98 parts of ultra-fine particle size magnesium hydroxide LHN-01, 1 part of CG-561, and 1 part of oleic acid were prepared according to the method of the above-mentioned flame retardant modifier C component to obtain C component.

[0064] Mix components A, B and C with a ratio of A:B:C=100:152:30 to obtain a flame retardant and high temperature resistant epoxy resin composition. Gel test, viscosity test, pot life test, exothermic peak test; prepare resin composition cast body and car...

Embodiment 3

[0070] 25 parts of E-51, 5 parts of NPEF-170, 8 parts of GE-30 and 62 parts of CEL-2021P were prepared according to the above resin A preparation method to obtain resin A component; 70 parts of methyl endomethylene tetrahydro Phthalic anhydride, 5 parts methyltetrahydrophthalic anhydride, 5 parts pyromellitic dianhydride, 2 parts PFNH9880, 15 parts Ricon-130MA-13, 1.5 parts polymethylphenylsiloxane, and 1.5 parts 2-ethyl-4 -Methylimidazole is prepared according to the above-mentioned curing agent B preparation method to obtain the curing agent B component; 95 parts of ultra-fine particle size magnesium hydroxide LHN-01 and 3 parts of CG-561, 2 parts of stearic acid are flame-retardant according to the above The method of modifier C component is prepared to obtain C component.

[0071] Mix components A and B with a ratio of A:B:C=100:119:100 to obtain a flame-retardant and high-temperature-resistant epoxy resin composition. Take an appropriate amount of samples for a gel test a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com