Drilling fluid as well as preparation method and application thereof

A drilling fluid and inhibitor technology, applied in the field of drilling fluid, can solve the problems that the stability of the ester group is easily affected by high temperature, cannot meet the drilling requirements of ultra-high temperature wells, and the cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

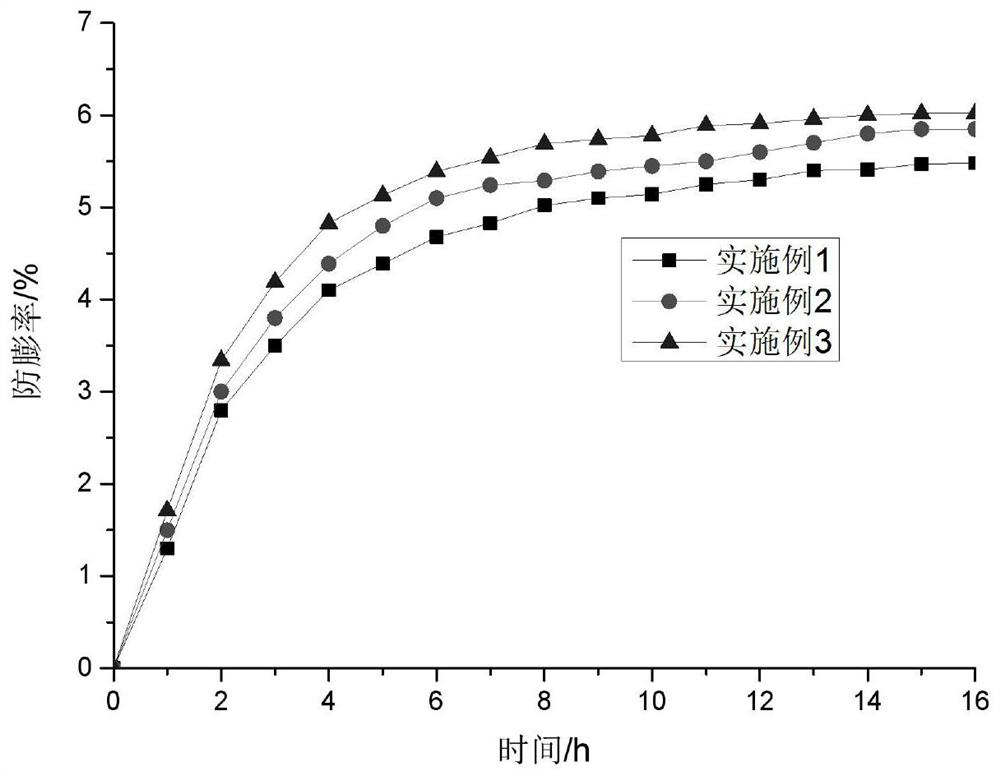

Examples

preparation example Construction

[0051] In the present invention, the preparation method of the organosilicon fluid loss control agent preferably comprises the following steps:

[0052] dissolving acrylamide, diallyldimethylammonium chloride and sodium styrene sulfonate to obtain a monomer solution;

[0053] The monomer solution, vinyltrimethoxysilane and benzoyl peroxide are mixed for free radical polymerization to obtain the organosilicon fluid loss control agent.

[0054] The invention dissolves acrylamide, diallyl dimethyl ammonium chloride and sodium styrene sulfonate to obtain a monomer solution. In the present invention, the dissolved reagent preferably includes a solvent, and the solvent preferably includes water. In the present invention, the dissolving of acrylamide, diallyldimethylammonium chloride and sodium styrene sulfonate is preferably carried out under the conditions of a protective atmosphere and stirring, and the protective atmosphere preferably includes nitrogen. After the acrylamide, di...

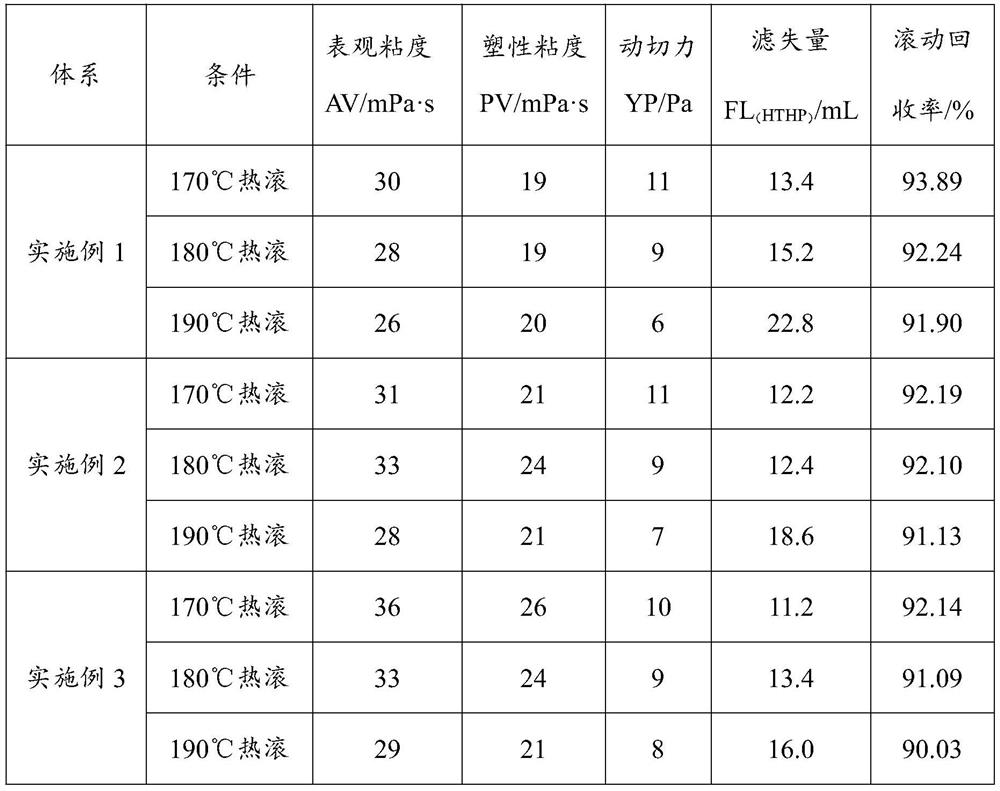

Embodiment 1

[0084] The anti-high temperature tackifier is a pentapolymer of 2-methyl-2-acrylamidopropanesulfonic acid, N-vinylpyrrolidone, acrylamide, acrylic acid and N,N-dimethylacrylamide, with a relative molecular mass of 1.3×10 6 . The synthesis steps are: weigh 10g 2-methyl-2-acrylamidopropanesulfonic acid, 15g N-vinylpyrrolidone, 10g acrylamide, 10g acrylic acid, 15g N,N-dimethylacrylamide and dissolve them in deionized water , add 0.2g of sodium persulfate as an initiator under the condition of flowing nitrogen for 30 minutes, and carry out a copolymerization reaction at a water bath temperature of 60° C. for 5 hours; filter the copolymerization reaction feed liquid, wash the obtained solid with absolute ethanol, and then vacuum-dry to obtain 2- Pentapolymer of methyl-2-acrylamidopropanesulfonic acid, N-vinylpyrrolidone, acrylamide, acrylic acid and N,N-dimethylacrylamide.

[0085] The preparation method of organosilicon inhibitor comprises the steps: in the three-necked round-b...

Embodiment 2

[0091] The preparation method of the anti-high temperature tackifier and the silicone inhibitor is the same as in Example 1.

[0092] The preparation method of organosilicon fluid loss reducer comprises the following steps:

[0093] Weigh 20g of acrylamide, 10g of diallyldimethylammonium chloride and 10g of sodium styrene sulfonate and dissolve in 250g of deionized water, adjust its pH to 8 with NaOH, and add three outlets with a reflux spherical condenser and a stirrer In the round-bottomed flask, raise the temperature to 60°C, and pass nitrogen gas for 30 minutes; add 1.5 g of vinyltrimethoxysilane dropwise at a rate of 0.3 g / min, then add 0.2 g of benzoyl peroxide, and keep the temperature Under the conditions of changing, stirring and filling with nitrogen, react for 12 hours; filter the reaction material liquid completely, put the obtained solid in a vacuum drying oven and dry to obtain a light yellow solid, that is, the organic silicon fluid loss additive.

[0094] Dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com