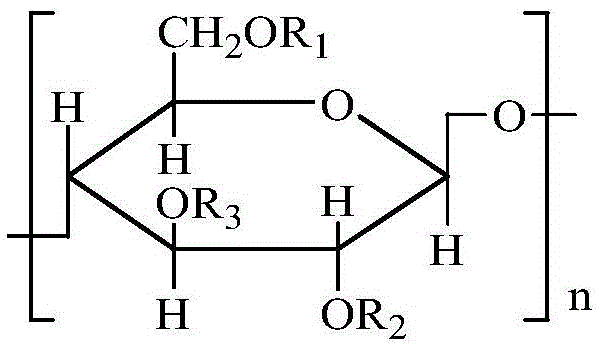

Amphiphilic starch filtrate reducer for water-based drilling fluid and preparation method thereof

A technology of water-based drilling fluid and fluid loss control agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no amphiphilic starch, etc., and achieve the effect of good compatibility and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

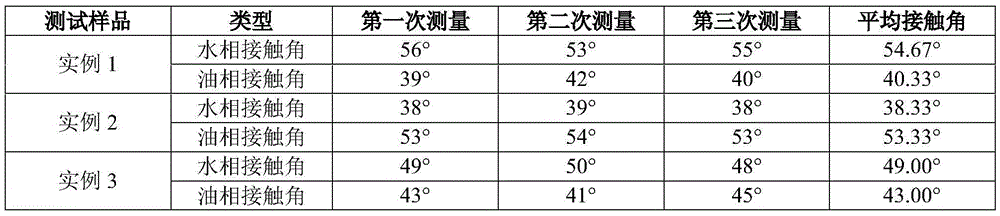

example 1

[0030] Weigh 1000 parts of starch, add it to a three-necked flask, then add 100 parts of methanol, place the three-necked flask in a water bath with a temperature of 35°C, and stir for 30 minutes at a speed of 300 rpm; add 100 parts of sodium hydroxide and 2000 parts of water, continue to stir for 30 minutes; sequentially add 100 parts of sodium hydroxide, 300 parts of chloroacetic acid, 200 parts of methanol, heat up to 60 ° C, and react for 60 minutes; cool to room temperature (10 ° C), add 100 parts of sodium carbonate and 0.5 parts of Chloroform, continue to stir for 10 minutes; add 100 parts of sodium carbonate and 800 parts of acrylic acid in sequence, raise the temperature to 40 ° C, and stir at a speed of 500 rpm for 30 minutes, during which nitrogen gas is introduced; add 10 parts of ammonium persulfate, and heat up to 70 ° C, Continue to react for 120 minutes; stop stirring, lower the temperature to room temperature (10°C), and continue to stand for 120 minutes, disch...

example 2

[0032] Weigh 1000 parts of starch, add it to a three-necked flask, then add 200 parts of methanol, place the three-necked flask in a water bath with a temperature of 35°C, and stir at a speed of 300 rpm for 30 minutes; add 150 parts of sodium hydroxide and 2500 parts of water, continue to stir for 30 minutes; sequentially add 100 parts of sodium hydroxide, 400 parts of chloroacetic acid, 200 parts of methanol, heat up to 60 ° C, and react for 70 minutes; cool to room temperature (15 ° C), add 150 parts of sodium carbonate and 1.0 parts of Chloroform, continue to stir for 10 minutes; add 200 parts of sodium carbonate and 1500 parts of 3-phenyl-2-acrylic acid in sequence, raise the temperature to 50 ° C, stir at 500 rpm for 35 minutes, and feed nitrogen during this period; add 15 parts of persulfuric acid Potassium, heat up to 75°C, continue to react for 160 minutes; stop stirring, lower the temperature to room temperature (15°C), and continue to stand for 150 minutes, discharge;...

example 3

[0034]Weigh 1000 parts of starch, add it to a three-necked flask, then add 300 parts of methanol, place the three-necked flask in a water bath with a temperature of 35°C, and stir at a speed of 300 rpm for 30 minutes; add 200 parts of sodium hydroxide and 3000 parts of water, continue to stir for 30 minutes; sequentially add 200 parts of sodium hydroxide, 500 parts of chloroacetic acid, 300 parts of methanol, heat up to 60 ° C, and react for 80 minutes; cool to room temperature (25 ° C), add 200 parts of sodium carbonate and 0.8 parts of Chloroform, continue to stir for 10 minutes; add 150 parts of sodium carbonate and 1800 parts of acrylonitrile successively, heat up to 40 ° C, stir with 500 rpm for 40 minutes, and feed nitrogen at the same time; add 20 parts of cyclohexanone peroxide, and heat up to 80°C, continue to react for 180 minutes; stop stirring, lower the temperature to room temperature (25°C), and continue to stand for 180 minutes, then discharge; centrifuge, wash 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com