Fiber material modified melamine formaldehyde foam and preparation method thereof

A melamine formaldehyde and fiber material technology, applied in the field of melamine formaldehyde foam and its preparation, can solve the problems of undisclosed foam compression set and flame retardancy, low compressive strength, complicated preparation process, etc., and achieves improved utilization value and compression performance. Excellent, the effect of expanding the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

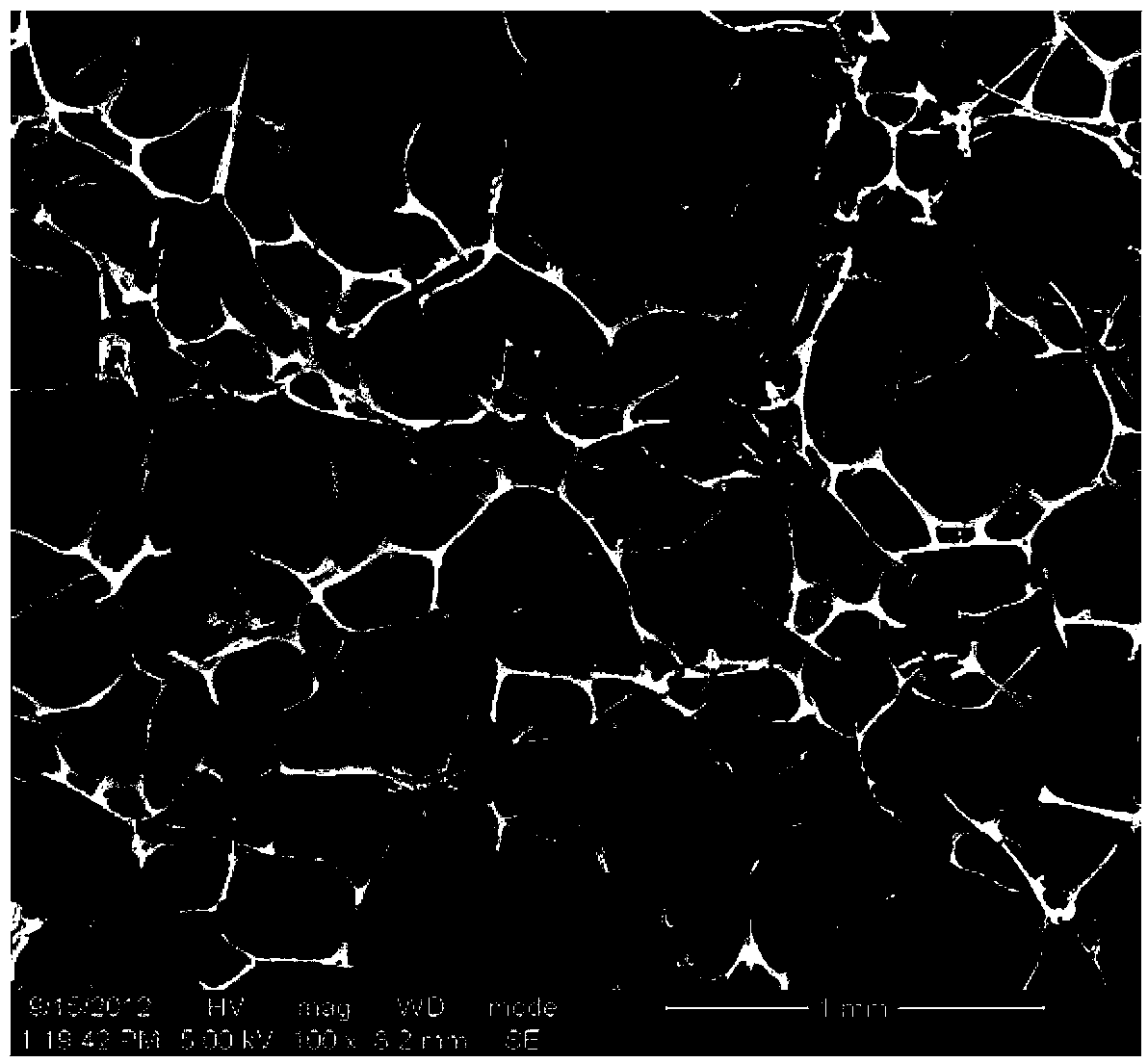

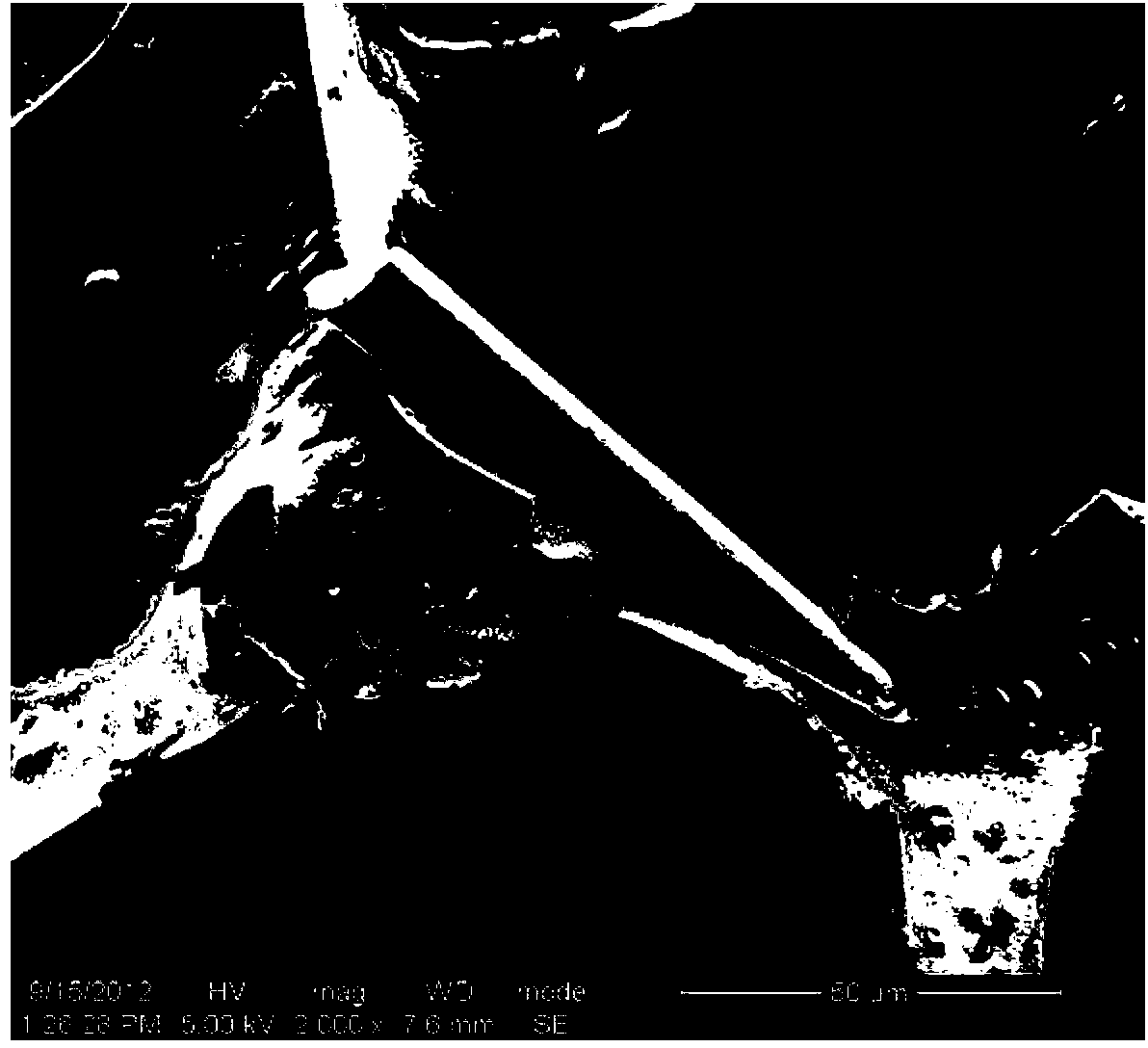

Image

Examples

Embodiment 1

[0042] (1) First adjust the pH value of 50ml of formaldehyde solution with a weight concentration of 37% to 8 with an aqueous sodium hydroxide solution (mass concentration of 30%, the same below), and then add 0.15g of unmodified glass with a diameter of 5um and a length of 1mm Fiber, mechanical stirring, after the fiber material is evenly dispersed, add 25g of melamine, react at 90°C for 1 hour, put it in an ice-water bath and cool to room temperature, and obtain the melamine-formaldehyde resin liquid modified with fiber material;

[0043] (2) First add 0.2 part of sodium dodecylbenzenesulfonate, 1 part of n-pentane and 1 part of formic acid into 100 parts of melamine formaldehyde resin liquid modified with fiber materials, and stir at 1500 rpm for 2 minutes to obtain milky white The foaming liquid, then pour the foaming liquid into the mold, foam at 80°C for 10 minutes, and then cure at 150°C for 1 hour.

[0044] The resulting foam density is 40g / L, its compressive strength ...

Embodiment 2

[0046] (1) First adjust the pH value of 25ml of formaldehyde solution with a weight concentration of 37% to 8.5 with sodium hydroxide aqueous solution, then add 0.15g of unmodified asbestos fibers with a diameter of 20um and a length of 2mm, stir mechanically, and wait for the fiber material to disperse evenly Finally, add 25g of melamine, react at 80°C for 2.5h, put it in an ice-water bath and cool it down to room temperature, and then obtain a melamine-formaldehyde resin solution modified with fiber materials;

[0047] (2) First add 0.2 parts of Tween-80, 5 parts of n-pentane and 1 part of acetic acid into 100 parts of melamine-formaldehyde resin liquid modified with fiber materials, and stir at a speed of 2000 rpm for 1 minute to obtain a milky white foaming liquid , and then pour the foaming solution into the mold, foam at 90°C for 8 minutes, and then cure at 180°C for 1 hour.

[0048] The obtained foam has a density of 30g / L, a compressive strength of 58kPa, a deformation...

Embodiment 3

[0050] (1) First adjust the pH value of 30ml of formaldehyde solution with a weight concentration of 37% to 9 with sodium hydroxide aqueous solution, then add 0.45g of unmodified carbon fiber with a diameter of 8um and a length of 3mm, stir mechanically, and wait until the fiber material is evenly dispersed Add 25g of melamine, react at 75°C for 4 hours, put it in an ice-water bath and cool it down to room temperature, and obtain a melamine-formaldehyde resin solution modified with fiber materials;

[0051] (2) First add 0.2 parts of sodium dodecylbenzenesulfonate, 10 parts of n-pentane and 2 parts of formic acid into 100 parts of melamine-formaldehyde resin liquid modified with fiber materials, and stir for 3 minutes at a speed of 1200rpm to obtain milky white The foaming liquid, then pour the foaming liquid into the mold, foam at 100°C for 6 minutes, and then cure at 200°C for 0.5h.

[0052] The obtained foam has a density of 30g / L, a compressive strength of 62kPa, a deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com