High-temperature-resistant filtrate reducer and preparation method thereof

A filtrate reducer, high temperature resistance technology, applied in the field of drilling fluid additives, can solve the problems of high cost, lack of high temperature resistance, ester group stability easily affected by high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

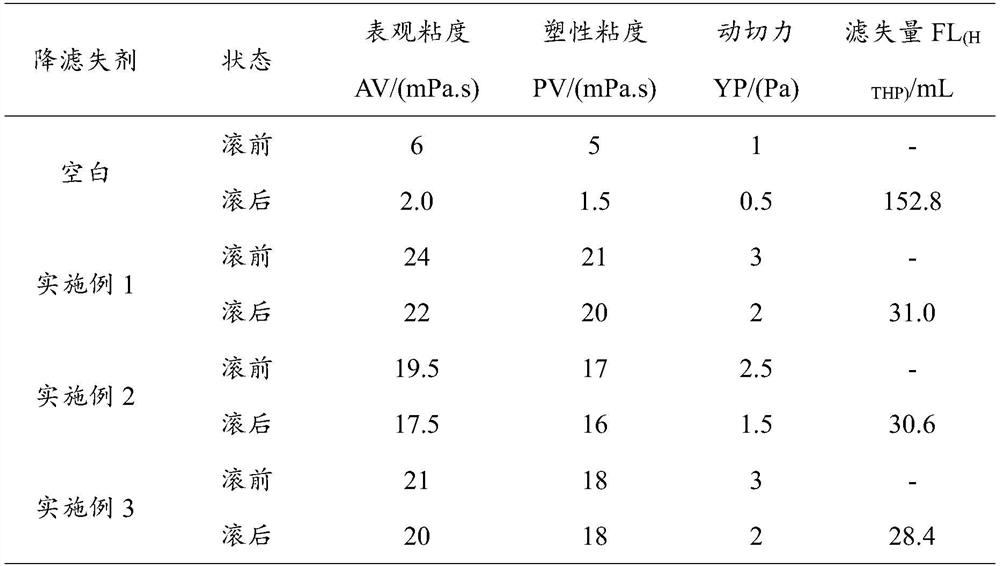

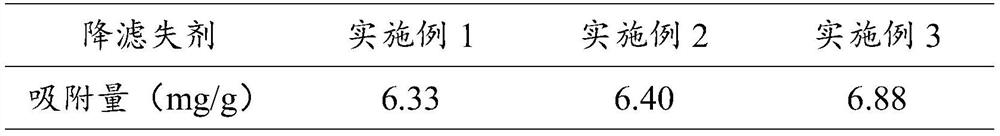

Examples

preparation example Construction

[0026] The raw materials for the preparation of the anti-high temperature fluid loss reducer provided by the present invention include 10-20 parts by weight of acrylamide, preferably 12-18 parts, more preferably 14-16 parts.

[0027] Based on the parts by weight of acrylamide, the raw materials for the preparation of the anti-high temperature fluid loss reducer provided by the present invention include 10 to 20 parts by weight of sodium styrene sulfonate, preferably 12 to 18 parts, more preferably 14 parts by weight. ~16 servings. Sodium styrene sulfonate monomer, the raw material for the preparation of high-temperature fluid loss reducer of the present invention, can make the fluid loss reducer molecules have rigid large side groups, and its steric hindrance is large. Under high temperature conditions, the molecular flexibility can be reduced. Then reduce the thermal movement of molecules, and finally improve the high temperature resistance of the fluid loss control agent.

...

Embodiment 1

[0050] Weigh 10g of acrylamide, 20g of sodium styrene sulfonate, and 15g of acrylic acid, dissolve them in 200g of deionized water, add them to a three-necked round-bottomed flask equipped with a reflux spherical condenser and a stirrer, adjust the pH of the solution to 7 with NaOH, and set the temperature Rise to 80°C, after 30 minutes of blowing nitrogen, add 2.0g of vinyltrimethoxysilane dropwise at a rate of 0.5g / min, then add 0.1g of benzoyl peroxide, keep the temperature constant, stir, and fill with nitrogen Under the following conditions, after 12 hours of free radical polymerization reaction, a free radical polymerization reaction feed liquid is obtained;

[0051] The free radical polymerization reaction feed liquid is filtered, and the obtained solid is placed in a vacuum drying oven to dry to obtain a light yellow solid, which is the target product high temperature resistant fluid loss reducer.

Embodiment 2

[0053] Weigh 15g of acrylamide, 10g of sodium styrene sulfonate, and 20g of acrylic acid, dissolve them in 200g of deionized water, add them to a three-necked round-bottomed flask equipped with a reflux spherical condenser and a stirrer, adjust the pH of the solution to 8 with NaOH, and set the temperature Rise to 70°C, after 30 minutes of blowing nitrogen, add 2.5g of vinyltrimethoxysilane dropwise at a rate of 0.5g / min, then add 0.2g of ammonium persulfate, under the conditions of keeping the temperature constant, stirring and filling with nitrogen , after free radical polymerization reaction 10h, obtain free radical polymerization reaction liquid;

[0054] The free radical polymerization reaction feed liquid is filtered, and the obtained solid is placed in a vacuum drying oven to dry to obtain a light yellow solid, which is the target product high temperature resistant fluid loss reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com