Low-noise centrifugal pump with staggered non-uniform symmetric impeller/guide vane structure

A non-uniform, low-noise technology, applied in the field of low-noise centrifugal pumps with staggered non-uniform symmetrical impeller/guide vane structure, can solve the problems of strong pump body vibration, influence of pump operation stability, pressure pulsation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

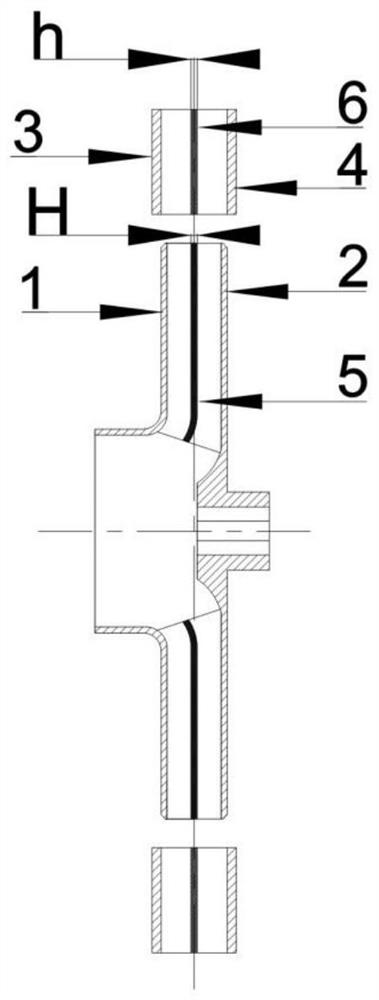

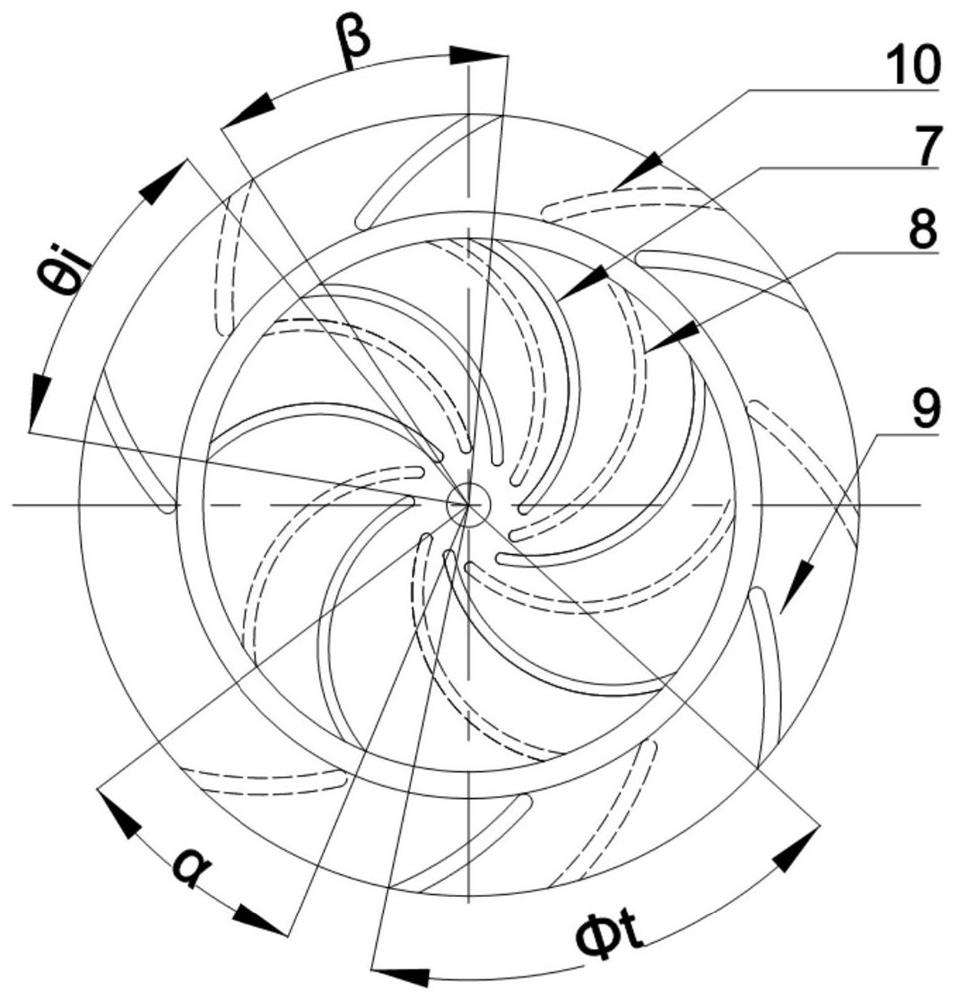

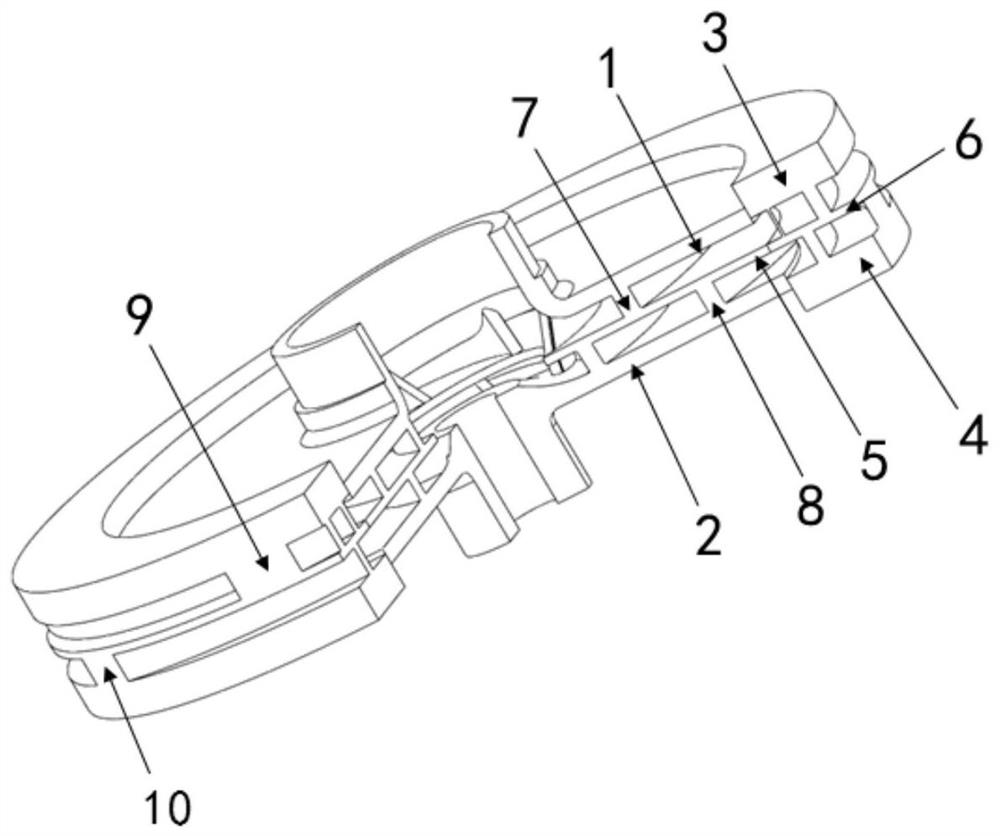

[0018] Such as figure 1 As shown, a rib is arranged in the middle of the impeller. The impeller rib starts from the impeller inlet and ends at the impeller outlet. The thickness of the rib is 1.0B. The impeller rib divides the impeller into two parts, which are respectively placed on both sides of the impeller rib. According to the number of impeller blades is 6, the two parts of the impeller are arranged staggered according to α=30° at the interval of this rib. A guide vane rib with the same thickness as the impeller rib is arranged in the guide vane at the same axial position. The guide vane rib starts from the guide vane inlet and ends at the guide vane outlet. The guide vane is divided into two parts, respectively placed On both sides of the guide vane rib, the number of guide vane blades is 5, and the two parts of the guide vanes are staggered according to β=36°.

[0019] In this design, the blades of the impeller and guide vane are arranged asymmetrically along the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com