Staggered centrifugal impeller with asymmetrically distributed blades

A centrifugal impeller, asymmetric technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, machines/engines, etc., to suppress static and dynamic interference, avoid excitation superposition effects, and reduce flow-induced noise energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

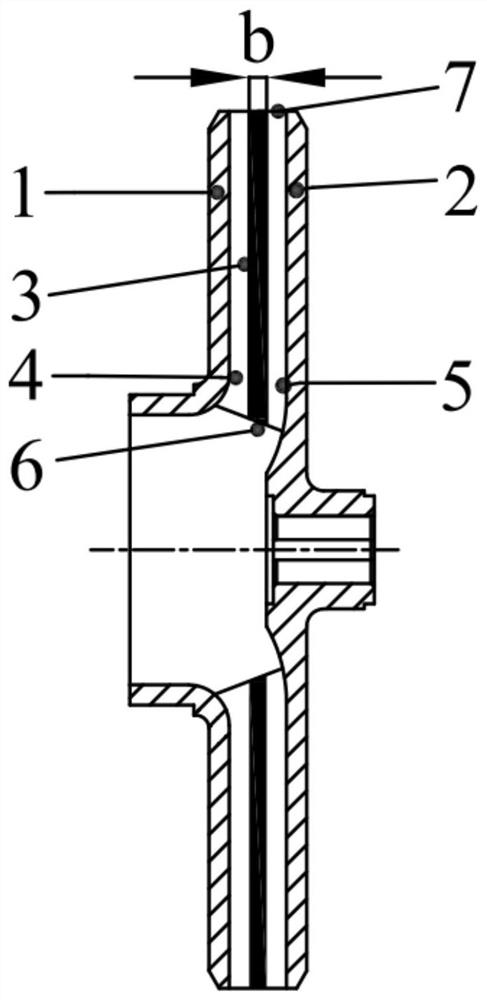

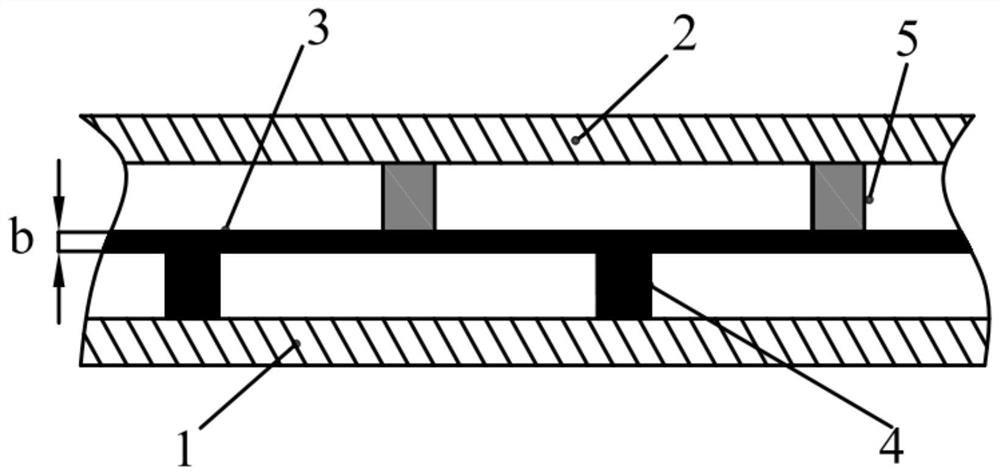

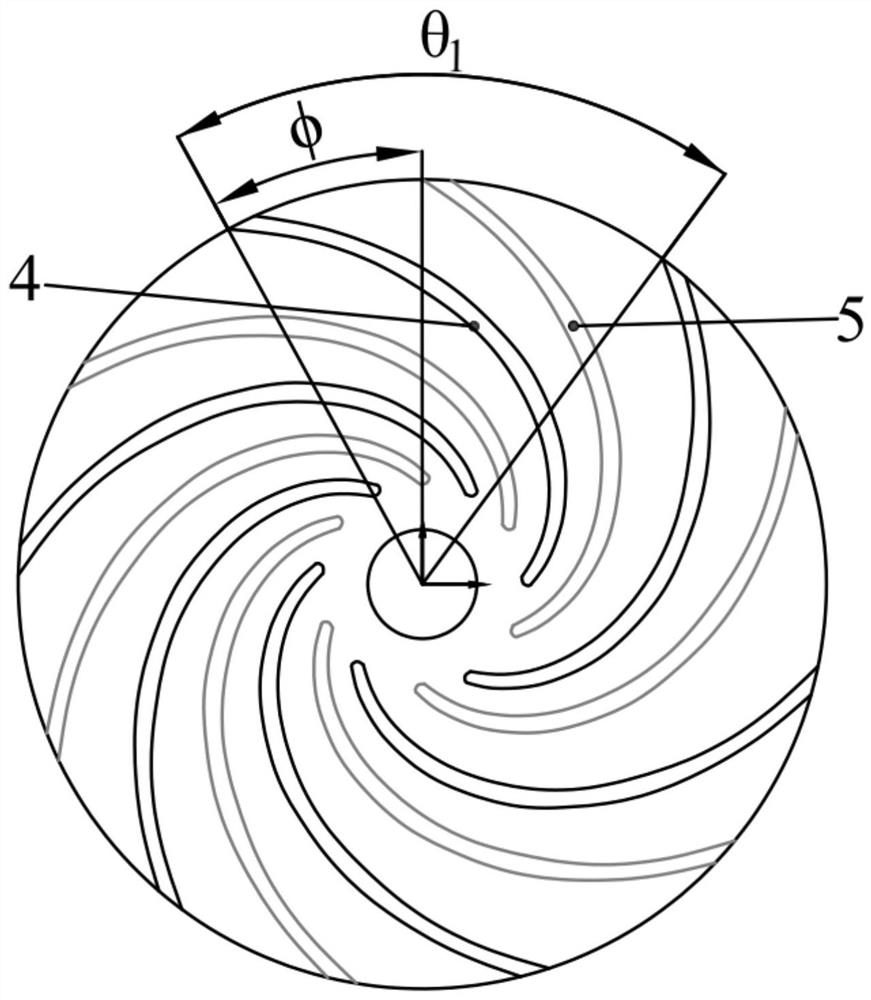

[0010] Such as figure 1 As shown, the middle rib 3 is located between the front cover plate 1 and the rear cover plate 2 of the impeller, and is in the center of the impeller flow channel. It starts from the blade inlet edge 6 and ends at the blade outlet edge 7, and divides the blade into independent The front half blade 4 and the rear half blade 5 are located at both sides of the middle rib 3 . When the number of middle ribs is 2-3, the impeller is divided into 2-4 layers. Such as figure 2 As shown, in this solution, the average thickness δ of the blade is 5 mm, and the thickness b of the middle rib 4 is 3 mm, which is 60% of the average thickness of the blade. Depend on image 3 It can be seen that the number of impeller blades in this scheme is 6, the front half blade 4 and the second half blade 5 are staggered after rotation, and the angle φ between them is 30°. The front half blades 4 and the second half blades 5 are arranged asymmetrically with the same rules along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com