Rotary piston engine having optimized internal cooling of intake air

A rotary piston, internal cooling technology, used in rotary piston engines, rotary or oscillating piston engines, internal combustion piston engines, etc., can solve problems such as maximum engine air volume limitation, insufficient engine cooling, limiting engine maximum power and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

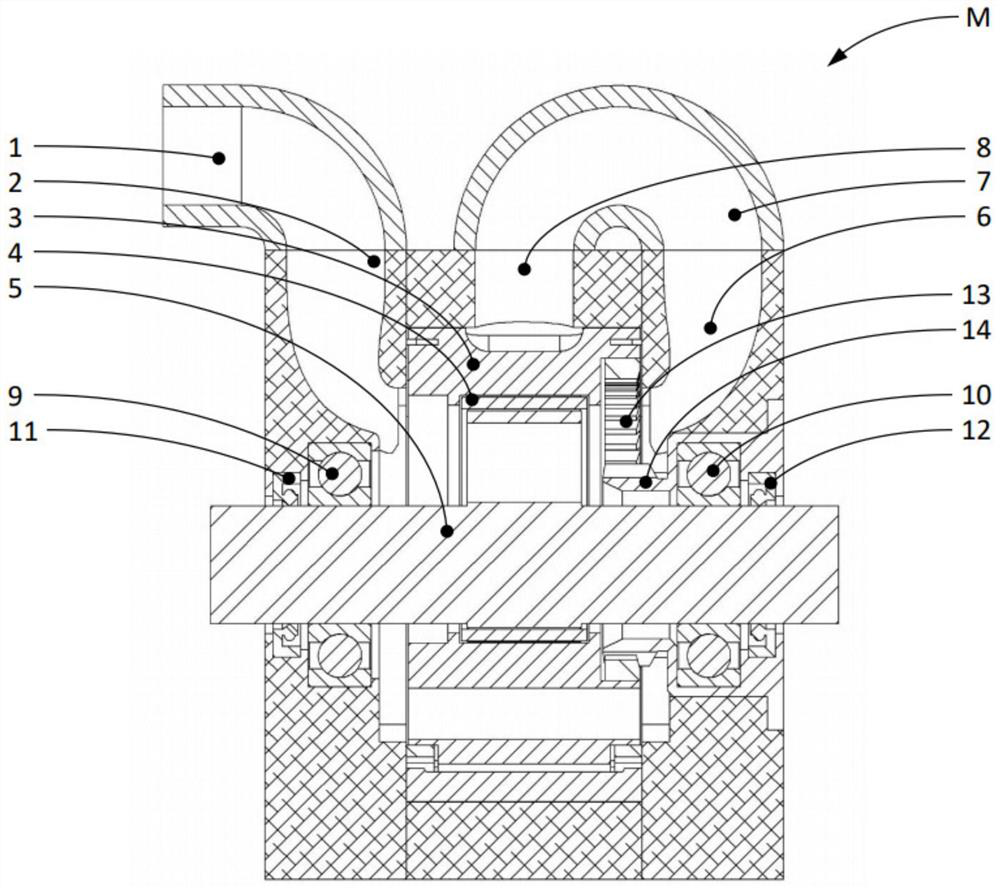

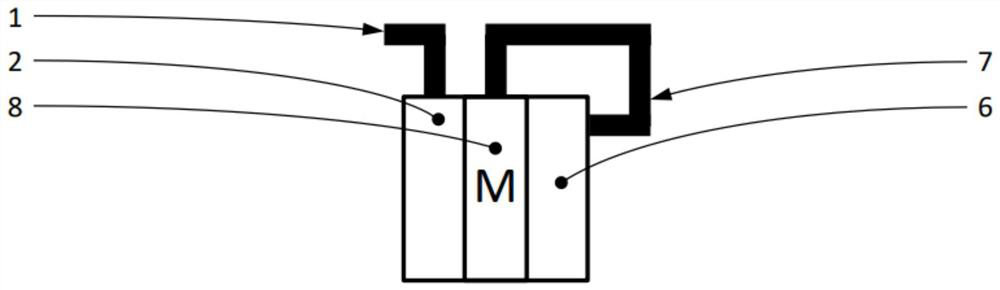

[0038] figure 1 Used to explain the components and shows a rotary piston engine in epicycloidal design with internal cooling (M) of the intake air in a sectional view through the central axis and the inlet channel. The figure shows the intake manifold (1), the side plate connected with the intake manifold (2), the rotor (3), the eccentric shaft (5), and the gap between the rotor (3) and the eccentric shaft (5). So-called main bearing (4), second side plate (6), trochoid (8) and bridge (7) as connection between side plate (6) and trochoid (8). Further shown are the side bearings (9, 10) of the eccentric shaft (5), the shaft seal rings (11, 12) for sealing the eccentric shaft (5), and the gears (13) and side plates in the rotor (3) Overview of the corresponding fixed gear (14) in (6).

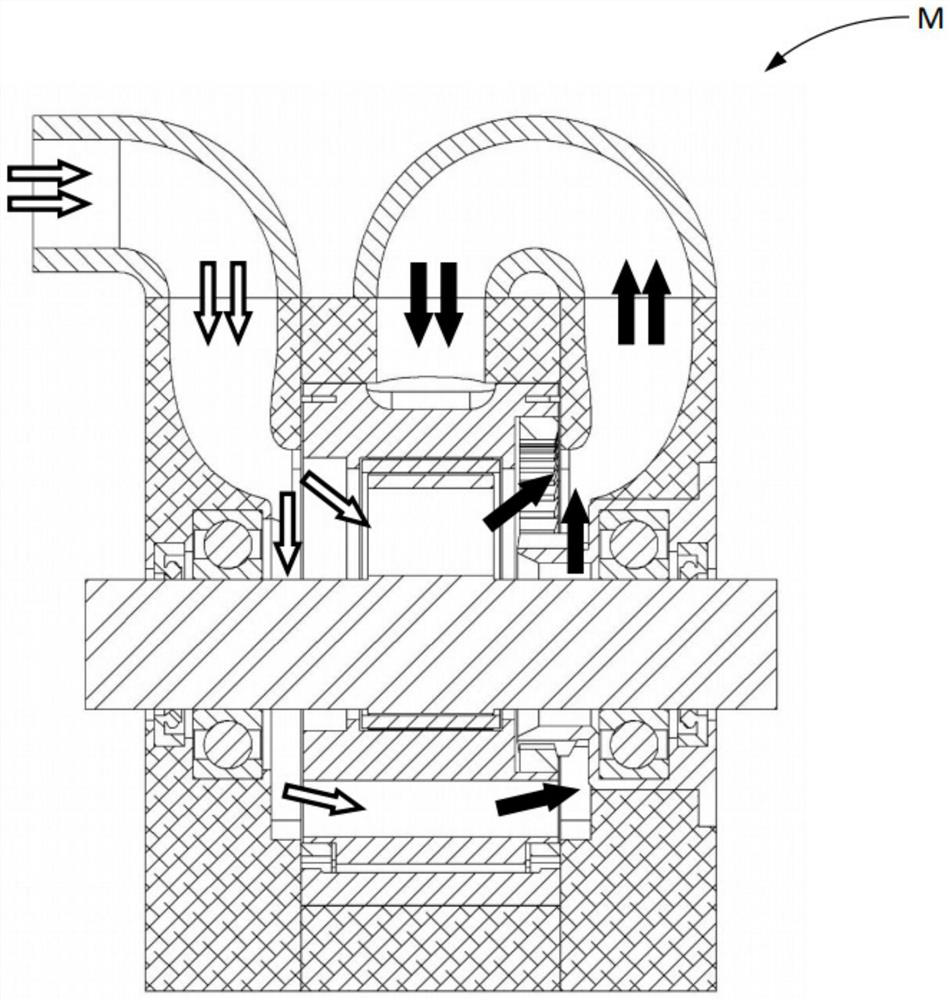

[0039] figure 2 based on figure 1 The sectional view of shows with arrows how the intake air flows through a rotary piston engine (M) of epicycloidal design with internal cooling of the inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com