A lightweight tailgate handle

A light-weight, hand-clasping technology, applied in the application of locks, building locks, construction, etc., can solve problems such as damage, inconvenient use of car trunks, etc., to reduce quality and cost, simple structure, and increase the length of force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

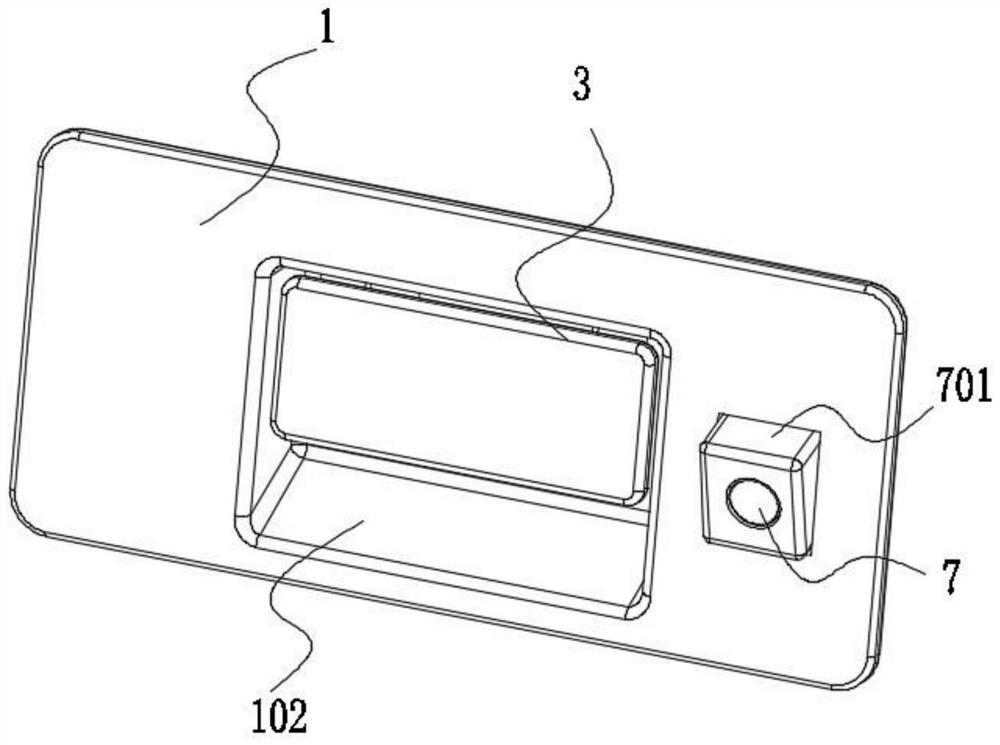

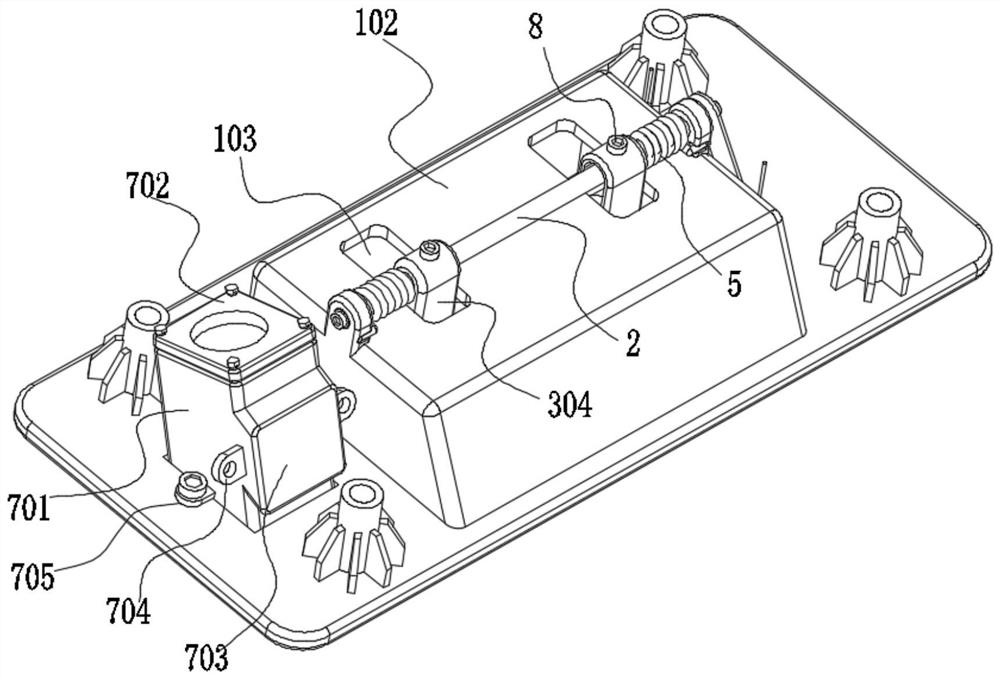

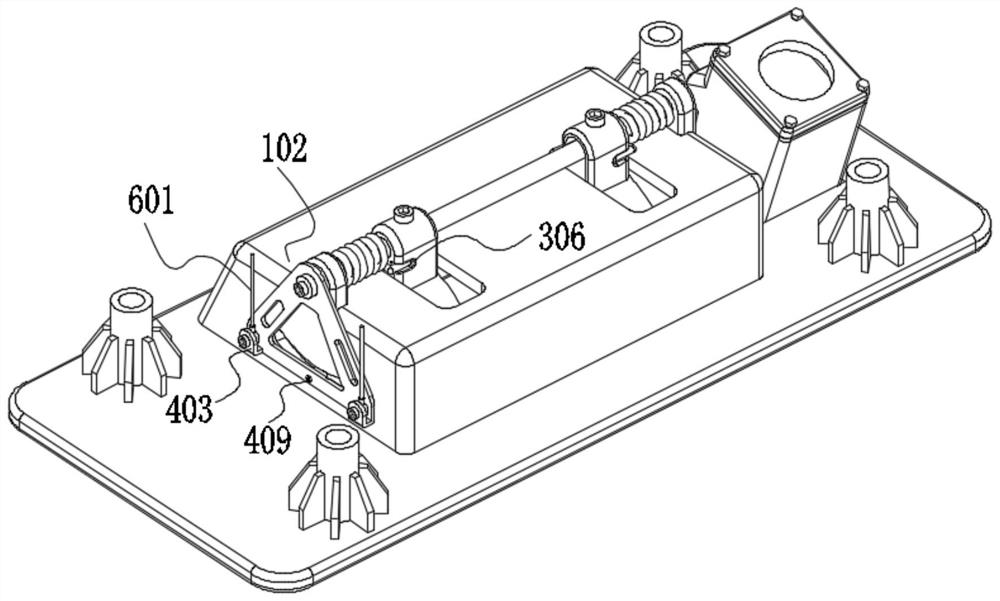

[0038] A lightweight tailgate handle of this embodiment includes a handle seat 1, a shaft rod 2, a handle 3, an arm frame 4, a torsion spring 5 and a wire foot 6 arranged on the tailgate of an automobile;

[0039] refer to Figure 1-4 and Figure 8 , the handle seat 1 is a plate body with a trapezoidal handle tank body 102 in the middle, and a transfer hole 103 is symmetrically opened on the side wall of the handle tank body 102 parallel to the handle seat 1. This technical solution transfers The hole 103 adopts a rectangular opening structure. The two sets of side walls on the outer side of the clasp groove body 102 and perpendicular to the clasp seat 1 are all integrally formed with a shaft seat 104. The shaft seat 104 is provided with a first shaft hole. One side of the shaft seat 104 The wall is provided with a first card slot 105 parallel to the axis of the first shaft hole, and at the same time, an arc-shaped slot 106 is provided on the outer wall of the clasping slot b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com