Low-pressure cylinder shaft seal steam flow testing device of high-pressure and intermediate-pressure combined cylinder turbine

A flow test device, high and medium pressure cylinder technology, applied in the direction of safety devices, mechanical equipment, engine components, etc., can solve problems such as non-installation, achieve the effect of less test instruments, improve operating efficiency, and have no installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

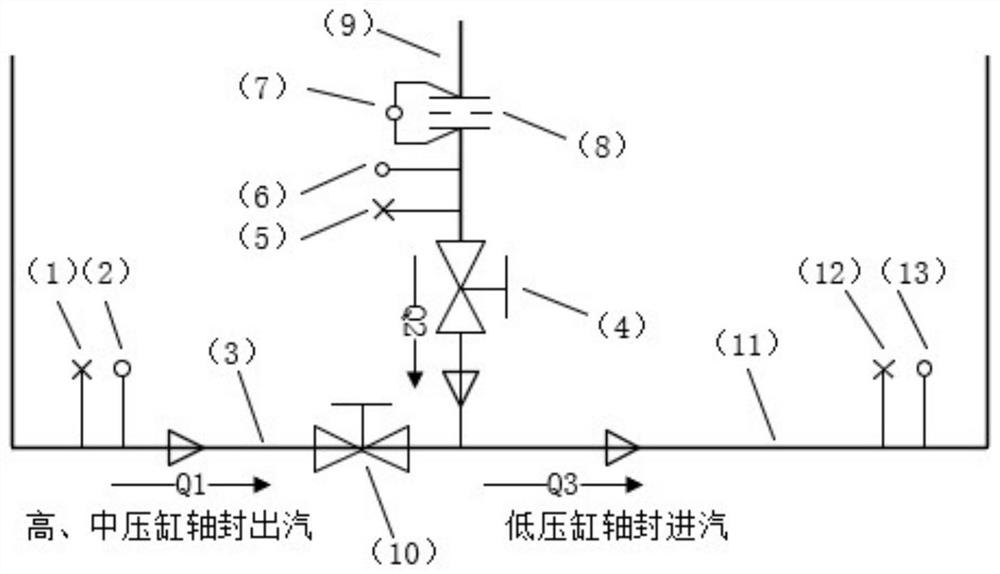

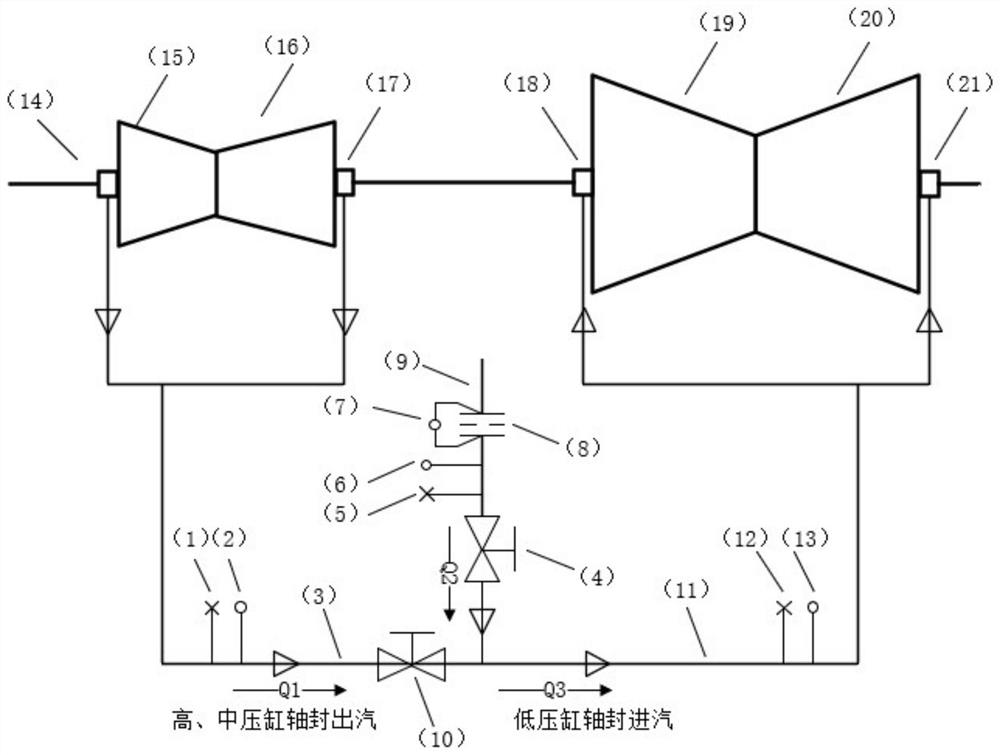

[0030] refer to figure 1 , figure 2 and image 3 .

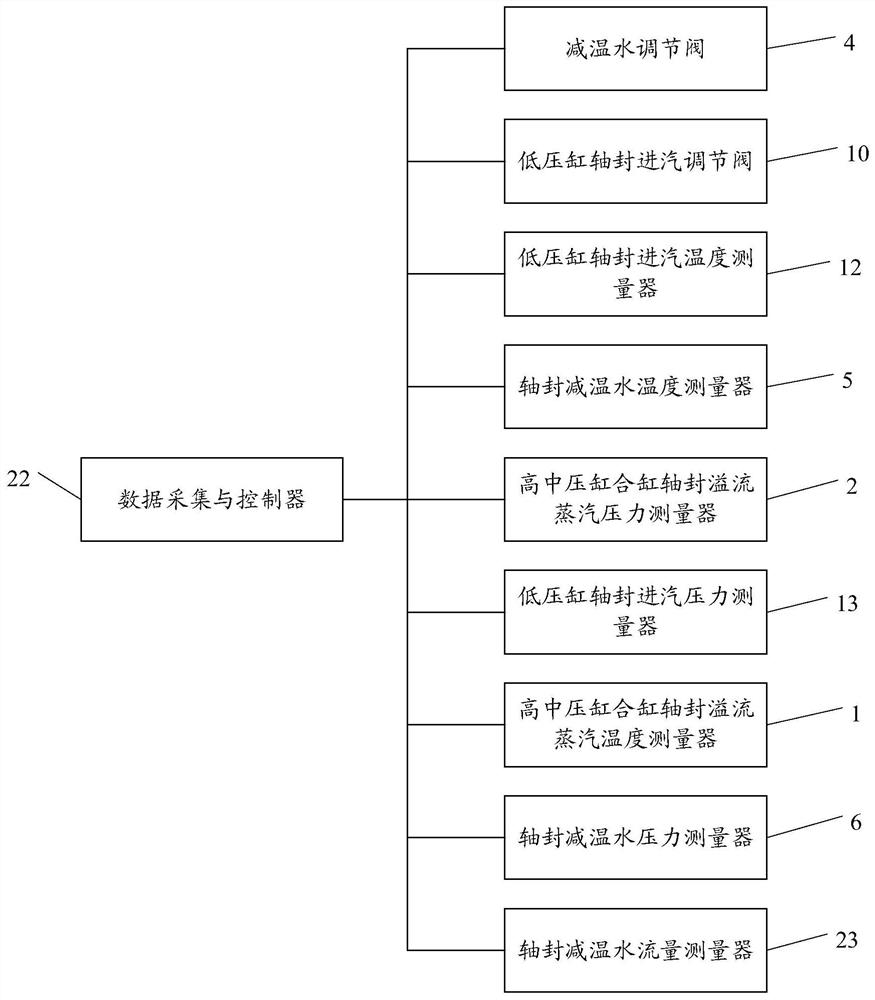

[0031] A cylinder shaft seal steam flow test device for a combination of high and medium pressure cylinders, the device includes a shaft seal cooling module, an outlet steam temperature and pressure detection module, an inlet steam temperature and pressure detection module, and an inlet steam regulating valve;

[0032] The outlet steam temperature and pressure detection module includes a high-medium pressure cylinder combined cylinder shaft seal overflow steam temperature measurer 1, a high-medium pressure cylinder combined cylinder shaft seal overflow steam pressure measurer 2; the inlet steam temperature and pressure detection module includes a low-pressure cylinder Shaft seal inlet steam temperature measuring device 12, low-pressure cylinder shaft seal inlet steam pressure measuring device 13; the shaft seal desuperheating module includes a desuperheating water regulating valve 4, a shaft seal desuperheating water temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com