Leakage current sensor

A leakage current sensor and current monitoring technology, which is applied in the direction of only measuring current, voltage/current isolation, measuring current/voltage, etc., can solve the problems that affect the working efficiency and stability of the system, low service life, laborious and laborious, etc., and achieve the solution The effect of unreliable connection, small contact resistance and high safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

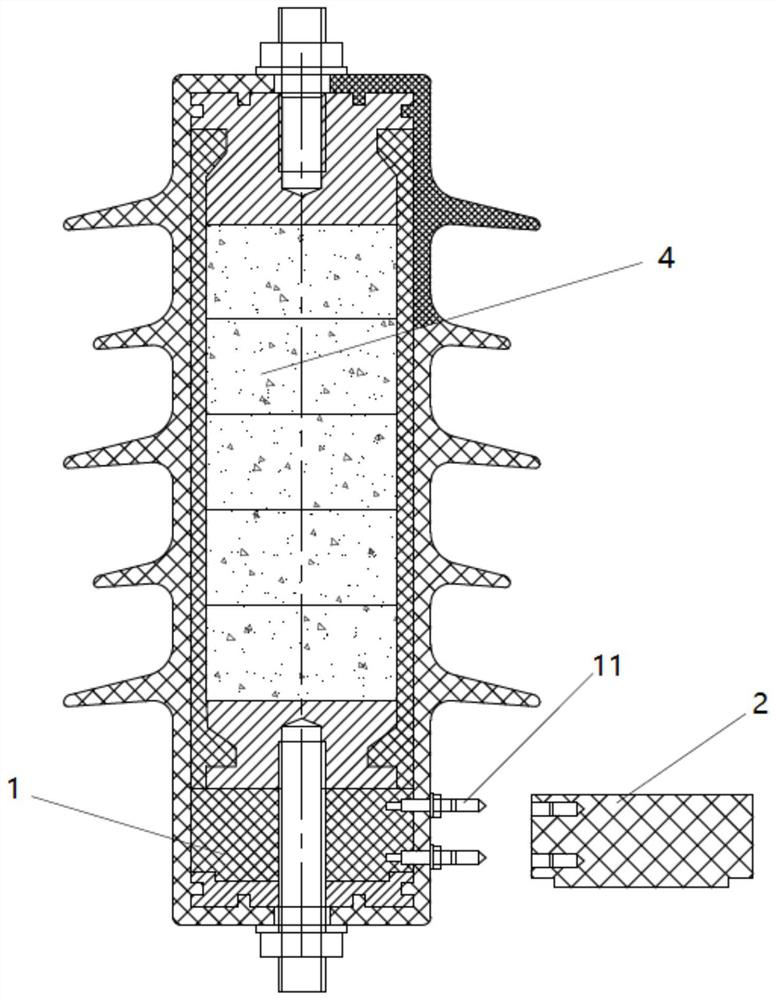

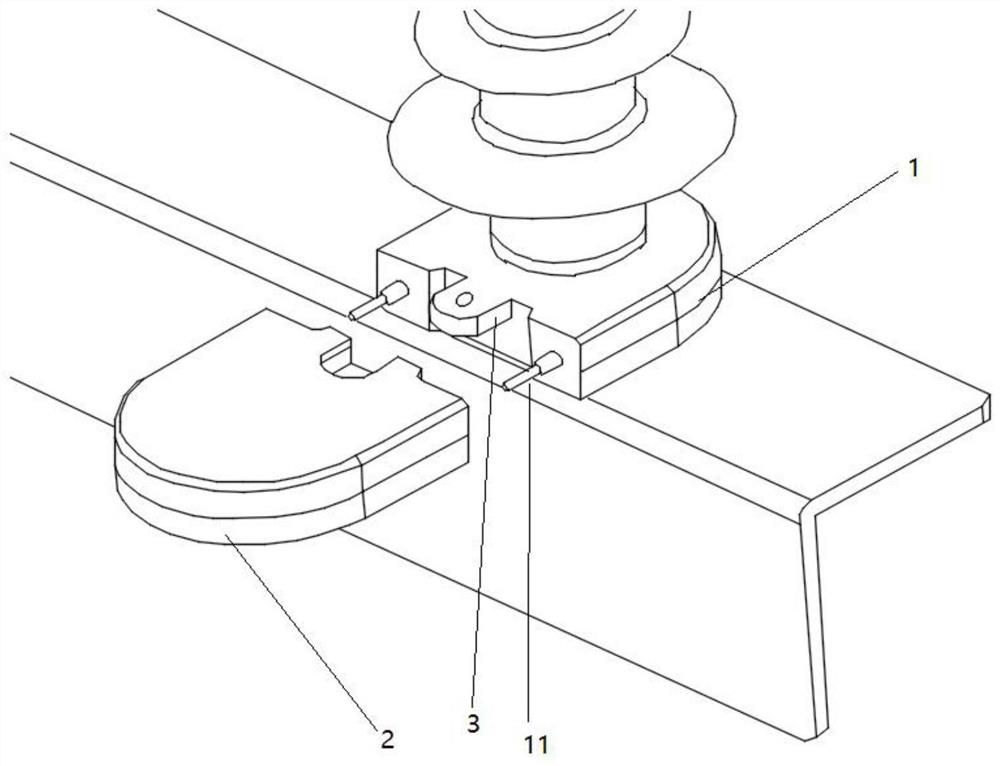

[0017] see figure 1 and figure 2 , a leakage current sensor of the present invention, the leakage current sensor is divided into a collection terminal 1 and a measurement terminal 2, the collection terminal 1 is provided with a connection terminal 11, and the measurement terminal is provided with a connection structure matching the connection terminal, the two are detachable Connect each other. The terminal block 11 adopts gold-plated cold-press connector, which has the advantages of waterproof, shockproof, wear resistance, corrosion resistance, and small contact resistance after special heat treatment and gold-plating process. The two ends of the gold-plated cold-press connector are respectively It is connected with the two parts of the acquisition end and the measurement end, which solves the problem of unreliable con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap