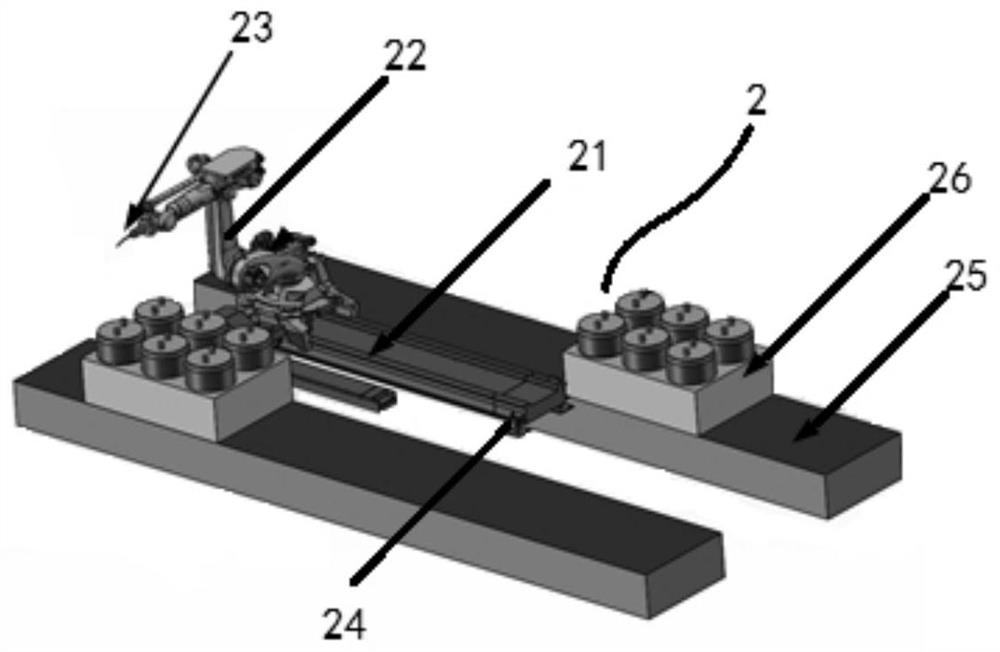

Robotic spraying system and method for automobile brake drum

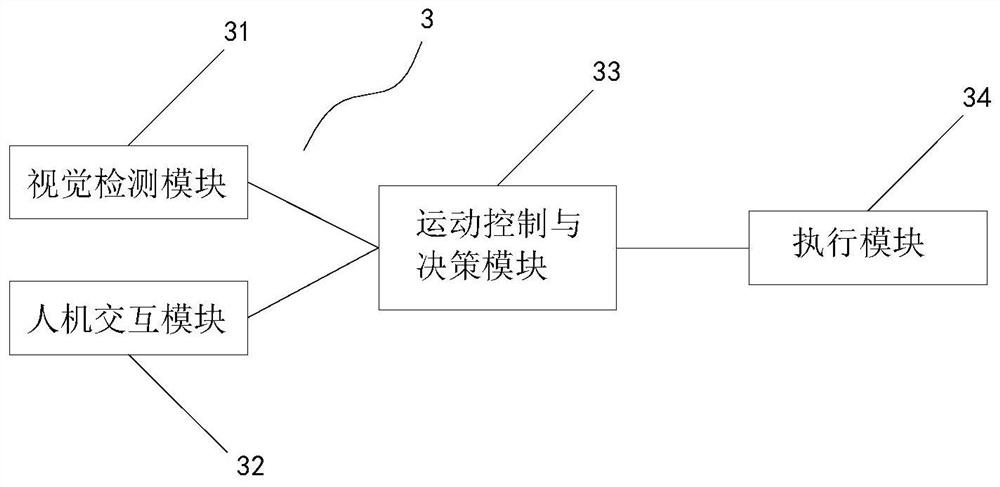

A technology of automobile brakes and robots, which is applied in coatings, manipulators, manufacturing tools, etc., can solve the problems of low processing efficiency of the automobile brake drum spraying system, improve spraying quality and equipment life, reduce manual intervention, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

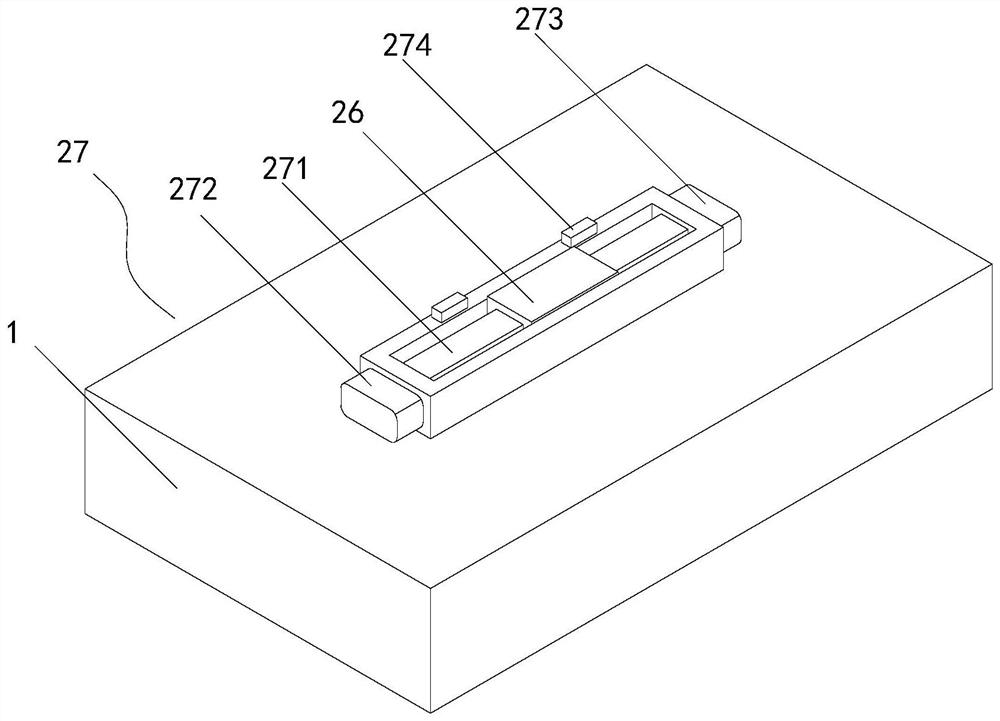

Embodiment Construction

[0034] The following examples of the present invention are described in detail. The example of the embodiment is shown in the attached figure. The same or similar labels from beginning to end indicate the same or similar components or components with the same or similar function. The implementation examples described by reference to the attachment are examples, which are designed to explain the present invention, and cannot be understood as restrictions on the invention.

[0035] 在本发明的描述中,需要理解的是,术语“长度”、“宽度”、“上”、“下”、“前”、“后”、“左”、“右”、“竖直”、 The position or location of the "level", "top", "bottom", "inside", "outside" is based on the orientation relationship shown in the attachment, just to facilitate description of the invention and simplified description, not the description of the present invention, not the description of the invention, not The instructions or suggestions that the device or components that are referred to must have a specific orientation, constructing and operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com