A kind of logistics small parcel quick unloading machine

A packaged and fast technology, applied in conveyors, loading/unloading, conveyor objects, etc., can solve the problems of small unloading space, impatient workers, and heavy workload, so as to reduce unloading time, reduce labor burden, shovel and shovel. The effect of stable cargo process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

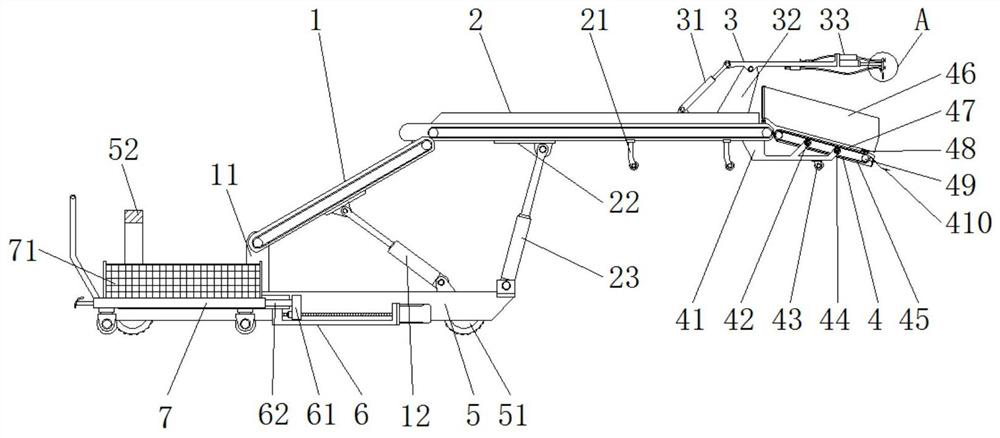

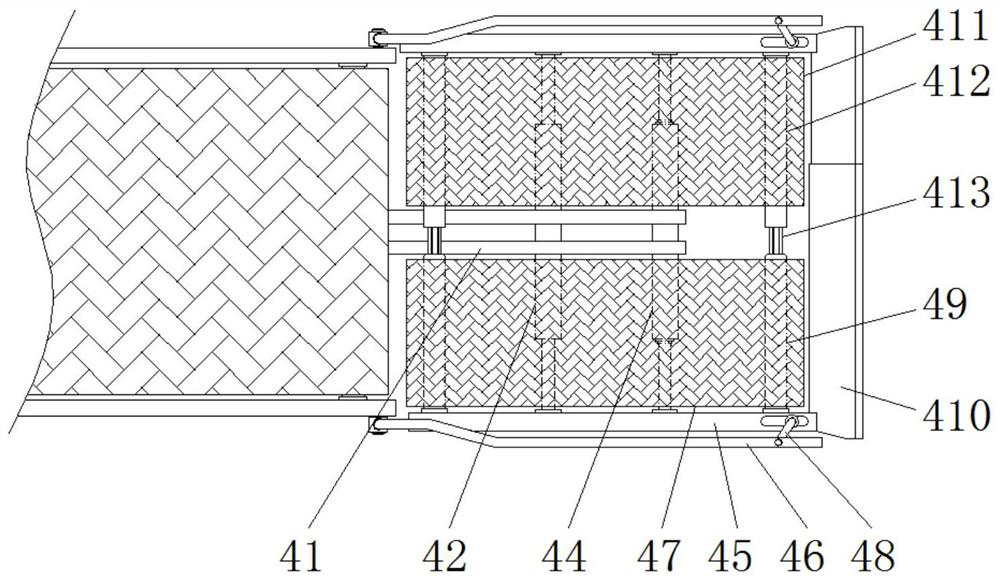

[0053] The present invention provides a quick unloading machine for logistics small parcels by improving, such as Figure 1-Figure 16 As shown, a logistics small package quick unloading machine includes a lifting conveyor 1, the lower end of the lifting conveyor 1 is rotatably connected with a mobile base 5, and a receiving trolley 7 is provided on the side of the mobile base 5 close to the lower end of the lifting conveyor 1, The upper end of the lifting conveyor 1 is movably connected with a horizontal conveyor 2, an adjustable conveying shovel 4 is arranged at one end of the horizontal conveyor 2 away from the lifting conveyor 1, and a shovel is arranged on the top of the horizontal conveyor 2 close to one end of the adjustable conveying shovel 4. Suction manipulator 3.

[0054] Through the cooperation of the adjustable conveying shovel 4 and the picking-sucking manipulator 3, the active batch reception of small parcels in the carriage can be realized, making the unloading ...

Embodiment 2

[0063] The present invention provides a quick unloading machine for logistics small parcels by improving, such as Figure 1-Figure 16 As shown, a logistics small package quick unloading machine includes a lifting conveyor 1, the lower end of the lifting conveyor 1 is rotatably connected with a mobile base 5, and a receiving trolley 7 is provided on the side of the mobile base 5 close to the lower end of the lifting conveyor 1, The upper end of the lifting conveyor 1 is movably connected with a horizontal conveyor 2, an adjustable conveying shovel 4 is arranged at one end of the horizontal conveyor 2 away from the lifting conveyor 1, and a shovel is arranged on the top of the horizontal conveyor 2 close to one end of the adjustable conveying shovel 4. Suction manipulator 3.

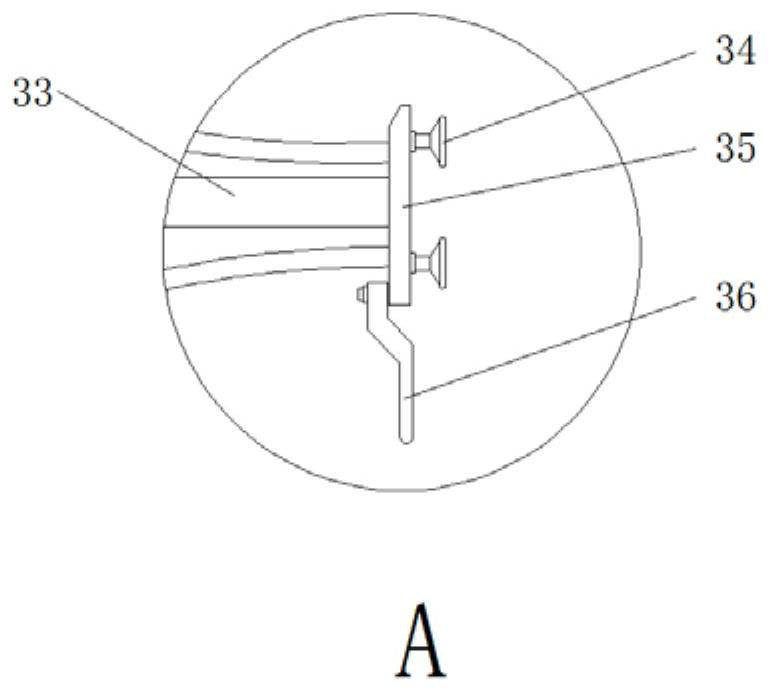

[0064] As a further optimization of this technical solution, the middle part of the picking manipulator 3 is connected to the horizontal conveyor 2 through the support frame 32, the support frame 32 and th...

Embodiment 3

[0068] The present invention provides a quick unloading machine for logistics small parcels by improving, such as Figure 1-Figure 16 As shown, a logistics small package quick unloading machine includes a lifting conveyor 1, the lower end of the lifting conveyor 1 is rotatably connected with a mobile base 5, and a receiving trolley 7 is provided on the side of the mobile base 5 close to the lower end of the lifting conveyor 1, The upper end of the lifting conveyor 1 is movably connected with a horizontal conveyor 2, an adjustable conveying shovel 4 is arranged at one end of the horizontal conveyor 2 away from the lifting conveyor 1, and a shovel is arranged on the top of the horizontal conveyor 2 close to one end of the adjustable conveying shovel 4. Suction manipulator 3.

[0069] As a further optimization of this technical solution, the bottom of the horizontal conveyor 2 is slidably connected with a pedestal 22, the main body of the horizontal conveyor 2 is a belt conveyor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com