Meat product processing material transportation device with metering function

A technology for transportation devices and meat products, applied in the directions of measuring devices, transportation and packaging, weighing indicating devices, etc., can solve the problems of labor, trouble, and inability to measure and display the weight of meat products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

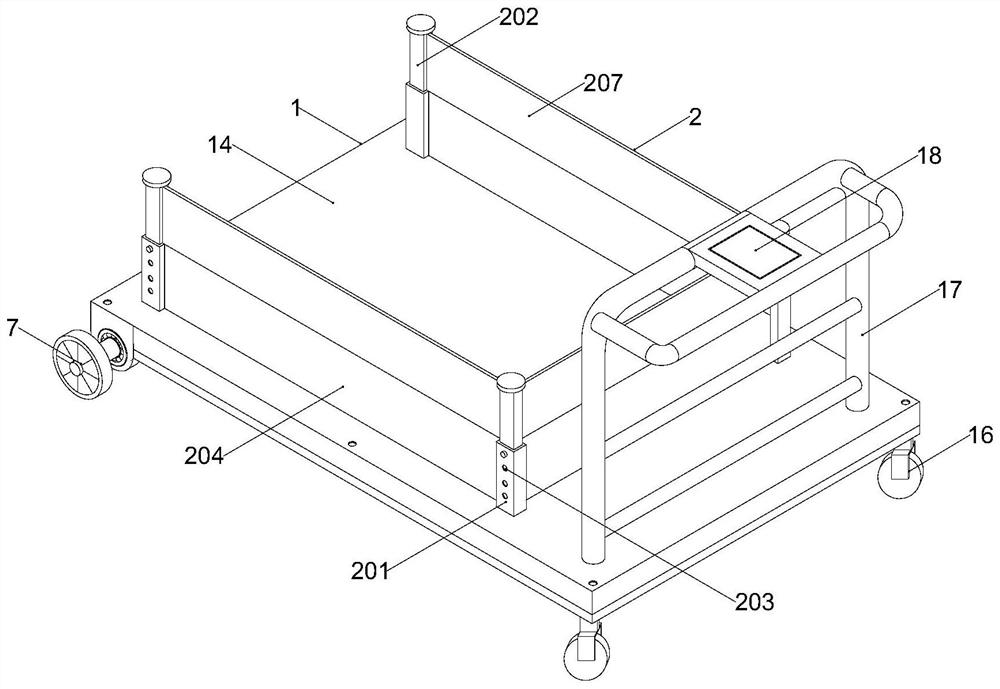

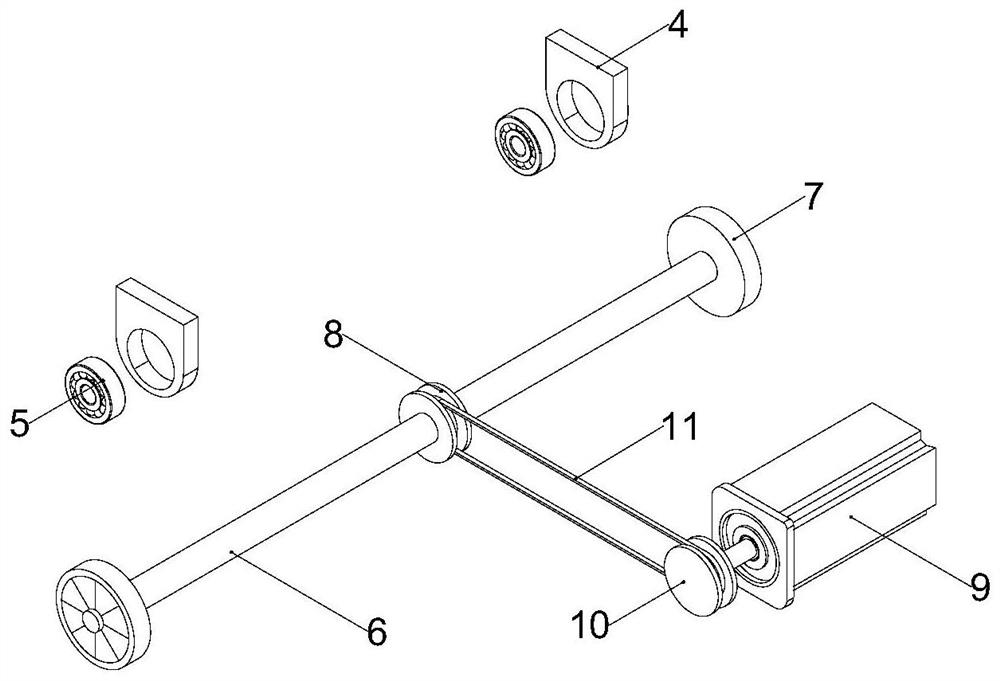

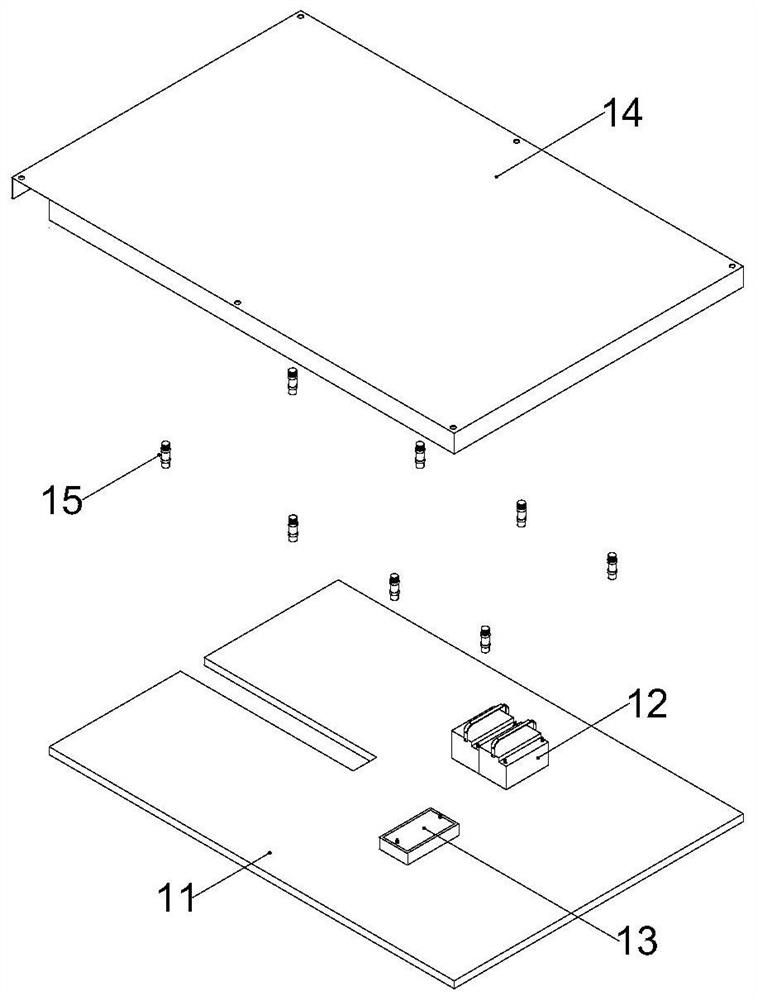

[0027] Example: such as figure 1 As shown, a material transportation device for meat product processing with a metering function in the present invention includes a transportation device body 1 and a blocking mechanism 2. The transportation device body 1 includes a bottom plate 3, and a load-bearing plate 14 is arranged on the top of the bottom plate 3. The load-bearing plate The top of 14 is provided with a blocking mechanism 2, and the blocking mechanism 2 includes four fixed pipes 201, and the tops of the four fixed pipes 201 are all provided with sleeves 202.

[0028] Among them, the bottoms of the four fixed pipes 201 are fixedly connected with the four corners of the top of the bearing plate 14, the first baffles 204 are arranged between the four fixed pipes 201, and the second baffles 204 are arranged between the four sleeve pipes 202. Baffle plate 207, through the first baffle plate 204 and the second baffle plate 207 that are provided with four fixed pipes 201 and fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com