Connecting structure of double-layer curtain wall

A technology for connecting structures and curtain walls, applied to walls, building components, building structures, etc., can solve the problems of no damping structure, deformation of the outer curtain wall, damage of the outer curtain wall, etc., and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

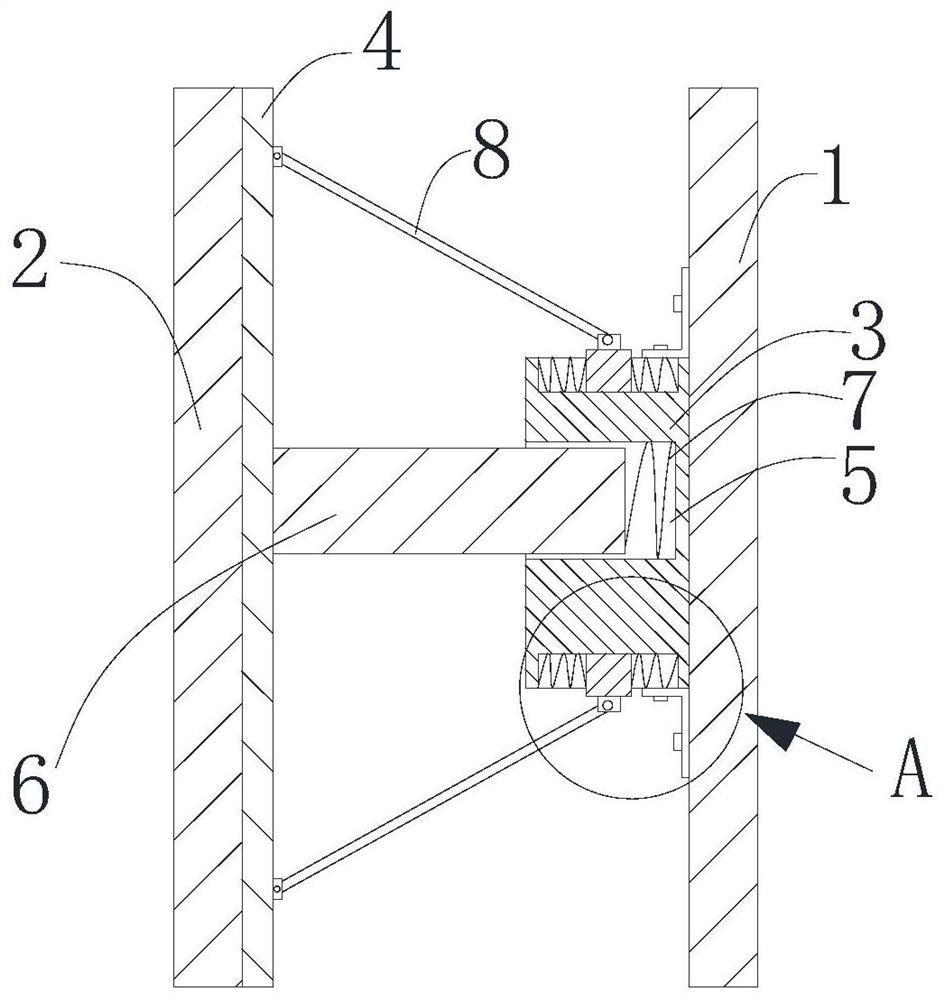

[0036] Such as figure 1 As shown, the present invention provides a connection structure of a double-layer curtain wall. The double-layer curtain wall includes an inner curtain wall 1 and an outer curtain wall 2. The inner curtain wall 1 is fixed on the building wall. The connection structure of the double-layer curtain wall includes: a supporting connection mechanism, a supporting The connection mechanism includes a support block 3 fixed on the inner curtain wall 1 and a fixed plate 4 fixed on the outer curtain wall 2. The support block 3 is provided with a limit groove 5, and the fixed plate 4 is provided with a limit groove 5. The matching limit rod 6, the free end of the limit rod 6 is located in the limit groove 5, and the limit spring 7 is arranged between the limit rod 6 and the bottom of the limit groove 5; the buffer damping mechanism, the buffer damping mechanism includes The connecting rod 8 and the sliding damping assembly, one end of the connecting rod 8 is hinged ...

Embodiment 2

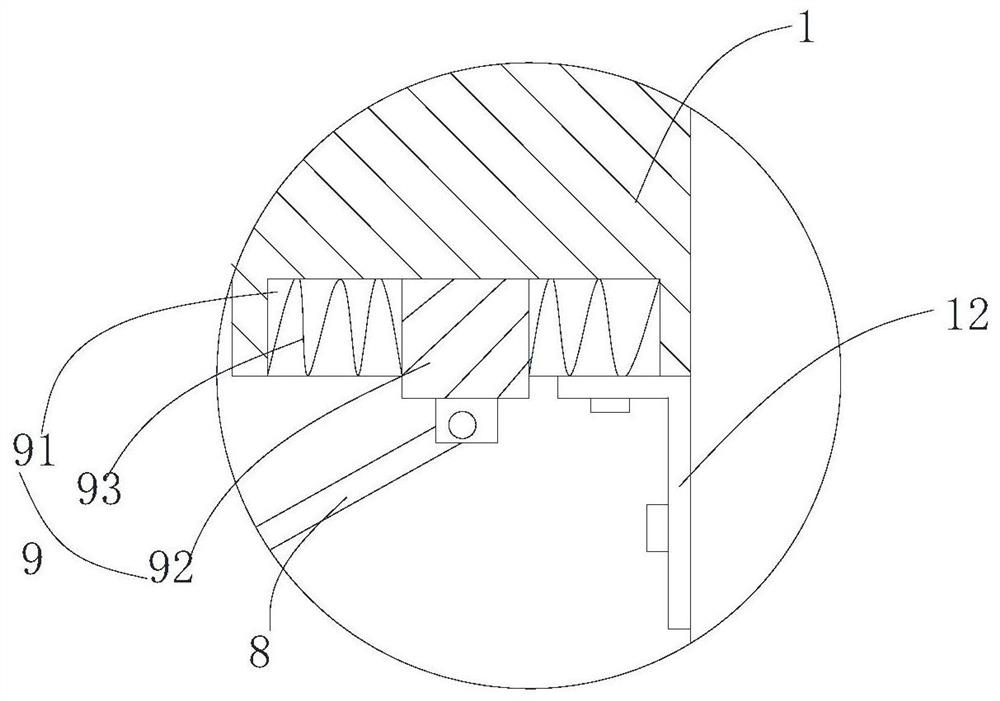

[0039] Such as figure 1 and figure 2 As shown, the difference between this embodiment and the above-mentioned embodiments is that the sliding damping assembly 9 includes a chute 91 arranged on the support block 3, and a sliding block 92 hinged with the connecting rod 8 is slidably provided in the chute 91, and the sliding block 92 Elastic pieces 93 are respectively arranged between the two ends of the chute and the two end walls of the chute 91 .

[0040] It can be understood that when the connecting rod 8 is forced to drive the slider 92 to move, the elastic member 93 will prevent the slider 92 from moving, thereby effectively playing a buffering role.

[0041] In some embodiments of the present invention, the elastic member 93 is a compression spring, and the compression spring is in a compressed state, which acts to abut against the slider 92 to prevent movement.

[0042] In some embodiments of the present invention, the elastic member 93 is a tension spring, and the ten...

Embodiment 3

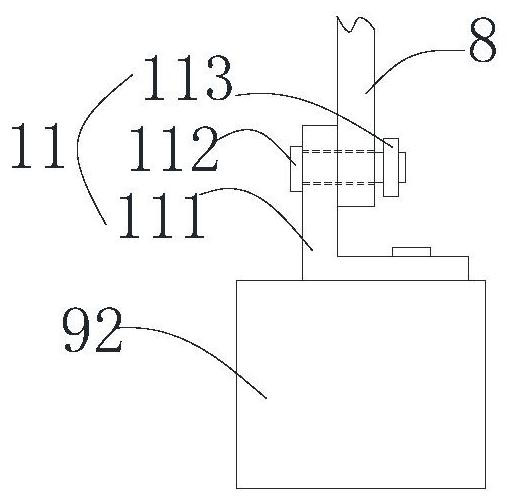

[0046]Such as figure 1 and image 3 As shown, the difference between the present embodiment and the first embodiment is that the connecting rod 8 and the sliding block 92 are connected through the gusset hinge assembly 11 .

[0047] It can be understood that the corner panel hinge assembly 11 realizes the hinge connection between the connecting rod 8 and the slider 92, and is convenient for disassembly and assembly.

[0048] In some embodiments of the present invention, the corner plate hinge assembly 11 includes a corner plate 111 and a hinge bolt 112, the horizontal side plate of the corner plate 111 is fixedly connected with the slider 92, and the vertical side plate of the corner plate 111 is provided with a first Through hole, the connecting rod 8 is provided with a second through hole, and the hinge bolt 112 passes through the first through hole and the second through hole in turn, and the vertical side plate of the connecting rod 8 and the gusset 111 can be realized co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com