Labor-saving driving switch for switching on and off of 40.5KV circuit breaker switch

A circuit breaker switch and drive switch technology, which is applied to contact drive mechanisms, high-voltage air circuit breakers, electric switches, etc., to achieve the effects of improving transmission efficiency, reducing precision requirements, and reducing input angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

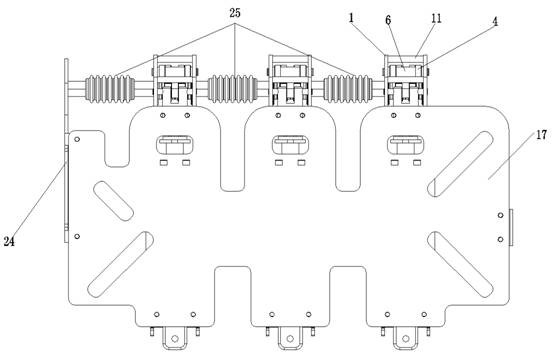

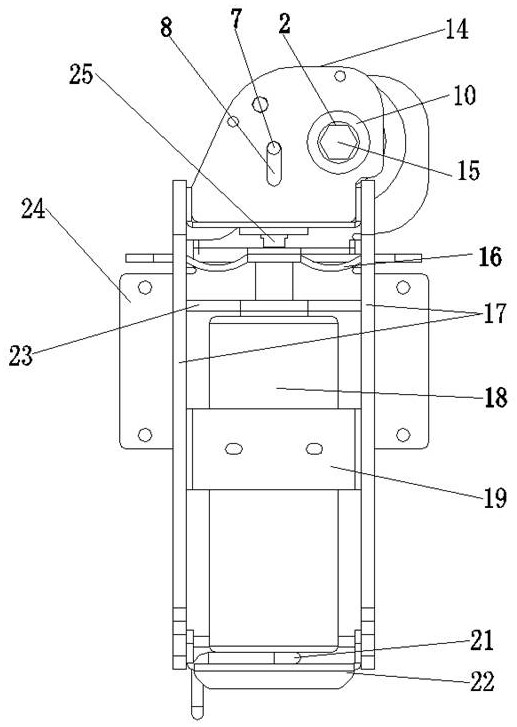

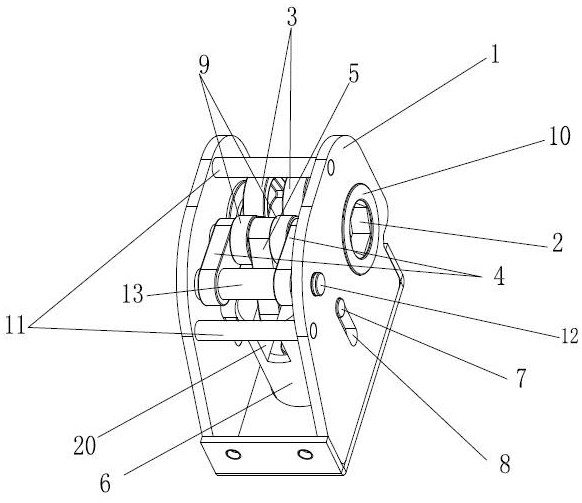

[0072] refer to Figure 1-18 , a 4.5kV circuit breaker closing and opening labor-saving driving switch, including a high-voltage switch closing and opening labor-saving driving structure 14, and also includes:

[0073] The base 1 is equipped with an inner hexagonal flange 2, and the inside of the base 1 is vertically connected with a reinforcing column 11 and a cam 3, which is set on the outer wall of the hexagonal insulating shaft 15, and rotates with the hexagonal insulating shaft 15 at the same time, and the swing of the two support arms 4 The end inner hole, the roller 9 inner hole and the upper end inner hole of the connecting rod 5 are hinged into one body through the coupling pin 28, and the fixed end of the support arm 4 is hinged on the support rod 12; the axial movement of the support arm 4 is limited by the positioning sleeve 13;

[0074] The support rod 12 is fixed to the base 1 through a snap ring, and the inner hole at the lower end of the link rod 5 is hinged wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com